SISO and MIMO Control Systems

Last Updated :

27 Feb, 2024

In Electronic Engineering, there are Two Key approaches in the field of control engineering are SISO (Single Input Single Output) and MIMO (Multiple Input Multiple Output) control systems, which are essential to the design and analysis of dynamic systems. SISO systems are designed to control or modify a particular variable with a single control input. These systems are useful for processes that have a single input and output. These systems are frequently employed in many different technological applications, such as motor control speed regulation, and temperature control in heating systems.

MIMO (Multiple Input, Multiple Output) systems are similar to control systems in that they handle scenarios in which numerous variables can simultaneously affect a wide range of outcomes. In today’s networked systems, this is essential because many components need to communicate with each other. In industries like robotics, airplanes, and chemical processes, where effective control and optimization need the consideration of several factors, MIMO control systems are extensively used.

In the fields of control theory and engineering, SISO and MIMO control systems are important, and solving a variety of real-world control issues requires an understanding of each system’s features and design concepts. The particular application requirements, system complexity, and intended performance results all play a major role in determining which of SISO and MIMO to choose.

SISO and MIMO Control System

In control systems, there are two basic categories: SISO (Single Input Single Output) and MIMO (Multiple Input Multiple Output). SISO systems have a single input and output, similar to having a single remote control for a single device. It is easy to operate and frequently used for simple jobs like changing the temperature in a single room. Everything is really straightforward; one thing directly affects another. MIMO systems, on the other hand, work more like a universal remote control and let you control multiple devices at once. Since each input affects several outputs in addition to its own, they are more complex. Consider it similar to controlling a multifunctional robot or organizing a sophisticated industrial process. Different methods are needed for these systems’ design and comprehension. For the design and understanding of these systems, several approaches are required. SISO systems are easier to understand and regulate than MIMO systems because there is a clear cause-and-effect relationship. MIMO systems require more

In control systems, a system or process that involves only one input and generates a single related output is referred to as Single Input Single Output, or SISO. The goal of SISO systems is usually to modify or control the output in accordance with the features of the input, as there is a clear and direct relationship between the input and the output. The structure’s simplicity facilitates a focused analysis of the system’s behavior and makes it easy to apply various control and signal processing techniques.

In many engineering applications, including automation, communications, and electronics, the primary objective is to regulate and optimize a single variable or parameter in response to a given input. This is where SISO systems come into play. Researching and designing SISO systems is crucial to understanding and enhancing the operation of many tools and procedures in the real world. An essential part of comprehending and improving the functioning of numerous devices and processes in the actual world is the research and design of SISO systems.

Single Input Single Output

Advantages

- The former are frequently easier to build and analyze.

- Stability analysis is usually simpler. Engineers can study and design controllers for stability.

- SISO control systems often have lower implementation and maintenance costs.

- SISO systems often have simpler troubleshooting and diagnosis since there are fewer intricate relationships between many inputs and outputs.

Disadvantages

- It is possible that SISO systems aren’t flexible enough to manage processes with plenty of inputs and outputs.

- SISO controllers may find it difficult to operate at peak efficiency in systems with plenty of interdependencies and variables.

- It could be challenging for SISO controllers to handle coupling effects between several variables.

Application

- SISO control systems are used to HVAC systems, heating, and air conditioning systems.

- SISO control is used in robotics and industrial automation, among other applications where precise motor speed control is essential.

- Storage tank liquid level is regulated using SISO systems. The liquid level is the output, and the liquid flow rate into the tank is the input.

- Power systems use SISO controllers to control voltage levels.

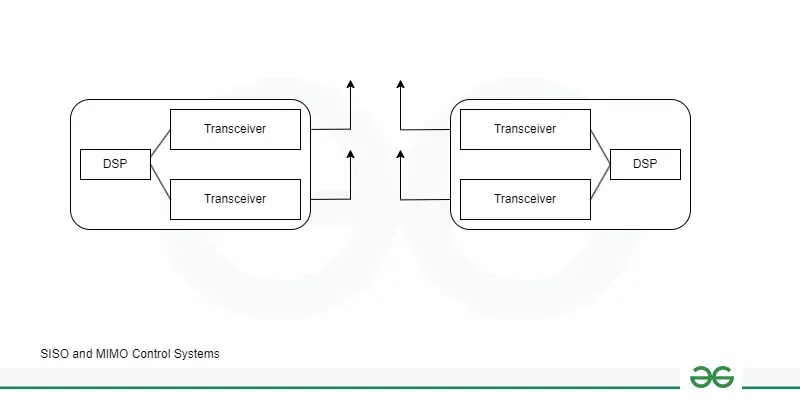

In control systems MIMO technology is like a cool upgrade for sending and receiving data. Instead of using just one antenna on each end, it uses a bunch of them.It functions similarly to several lanes on a freeway for the flow of data. Multiple antennas are used in MIMO transmission to send multiple streams of data, while many antennas are used in reception to gather the data. Multiple-antenna multiple-input multiplexing, or MIMO for short, is the fancy name for this procedure.

MIMO’s primary objectives are to increase data throughput, optimize the utilization of available frequencies, and ensure optimal system performance. It’s similar to supercharging your Wi-Fi. MIMO uses multipath propagation and spatial diversity to address signal difficulties, such as fading or interference. These are only technical terminology for ensuring that signals travel distinct routes to their intended locations, hence improving overall wireless system performance.

Also, the control strategies for MIMO systems are inherently more complex, requiring the consideration between various inputs and outputs. As compared to SISO systems, designing control techniques for MIMO systems is more difficult since these complex relationships must be taken into account. Multiplier transfer functions and state-space models are two ways matrices are used to represent MIMO systems. These representations offer a thorough picture of the contributions of each input to each output. Though they also bring extra design issues, the greater dimensionality and interconnectedness of variables in MIMO systems add to the richer representation.

Multiple Input Multiple Output

Advantages

- In situations where numerous variables need to be controlled simultaneously, MIMO systems can perform better than SISO systems.

- MIMO systems can adjust better to disturbances and shifting operational conditions. Responding to changes in the system can be done with more flexibility when there are various inputs and outputs.

- In order to achieve optimal system behavior, controllers can be built to take into account relationships between different inputs and outputs in addition to the setpoints for specific outputs.

- The controller is able to optimize the system’s functioning for energy efficiency by taking into account the relationships between variables.

Disadvantages

- MIMO systems have more inputs and outputs than SISO systems, they are by nature more complicated.

- MIMO systems frequently exhibit heightened sensitivity to errors in system modeling. Accurate modeling is essential because even tiny modeling mistakes can have a big effect on the control system’s performance.

- Compared to SISO systems, the implementation of MIMO control algorithms might need more advanced computational resources.

Application

- MIMO control systems are used to simultaneously manage numerous control surfaces in aircraft flight control. .

- Chemical facilities use MIMO systems to regulate a variety of parameters, including flow rates, pressure, and temperature. Variables that are altered, such as valve positions, are called inputs, and variables that are controlled are called outputs.

- Wireless communication systems having multiple antennas at the transmitter and receiver employ MIMO methods.

- Robotic systems with numerous actuators and sensors employ MIMO control systems.

Difference Between SISO and MIMO Control Systems

|

SISO

|

MIMO

|

|

In SISO, its has One input and one output

|

In MIMO, it has Multiple inputs and multiple outputs

|

|

Its is describe by a single transfer function

|

It is describe by a matrix of transfer functions

|

|

The design of SISO simple and easy

|

The design of MIMO is more complex due to interactions between multiple inputs and outputs

|

|

It has limited interaction between input and output

|

It has significant interaction between inputs and outputs

|

|

In SISO, we are easy to analyze and design

|

But in MIMO, it is more challenging due to coupling and interactions

|

|

Example : Temperature/Sensor Control Machine

|

Example : Aircraft Control System

|

Conclusion

In conclusion, the particular needs of the application and the complexity of the system being managed determine whether to use a Multiple Input Multiple Output (MIMO) or Single Input Single Output (SISO) control system. SISO systems provide ease of design and analysis and are appropriate for relatively basic processes with little interactions between variables. Applications such as liquid level management, motor speed regulation, and temperature control are commonplace.

FAQs on SISO and MIMO Control Systems

What are the difference between SISO and MIMO ?

In SISO, denotes the presence of a single controllable variable (output) and one manipulated variable (input), where MIMO, is an acronym that denotes the presence of numerous controlled and manipulated variables and permits more intricate control setups.

Which SISO control systems are commonly used for?

SISO control systems are frequently utilized in applications including voltage regulation in power systems, temperature control in HVAC systems, speed control in electric motors, and liquid level management in tanks.

Could you give instances of systems or industries that frequently use MIMO control?

Applications for MIMO control systems include robots, driverless cars, bioprocess control in biotechnology, chemical process industries for multiple variable management, and communication systems employing multiple antennas.

Does the choice between MIMO and SISO control systems impact the resilience and stability of the system?

Stability in SISO is usually easier to attain and analyze and MIMO possessing More sophisticated control techniques may be needed to successfully manage uncertainties and disturbances in order to achieve stability in MIMO systems.

Share your thoughts in the comments

Please Login to comment...