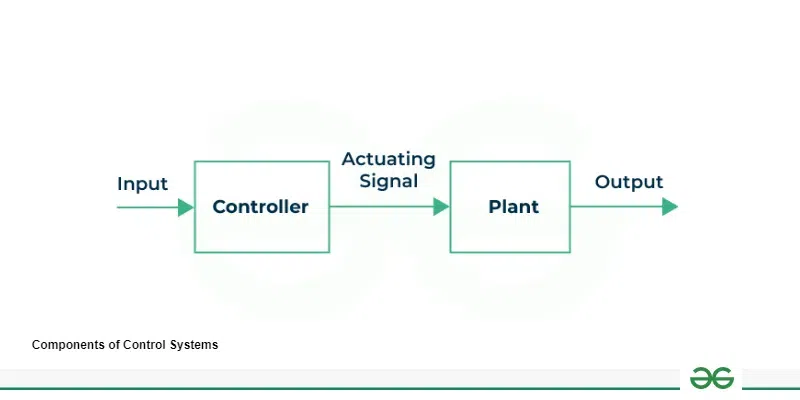

Components of Control Systems

Last Updated :

27 Feb, 2024

With the advancement of technology, Human dependency on control system have increased over years and are being used everywhere, playing significant role in our daily lives. Contributing to different applications, they made the work easier by reducing human effort and involvement. They are used to control the behavior of devices and systems to accomplish the desired task. Control system consist of different components which play significant role and work together to produce the desired output. Some of the major components of control system are controller, sensors and actuators. Sensors are used to convert physical changes into electrical signals. Controllers are used to adjust the functions in control system to get the desired result. In this article we will see the components of control system which made a complete control system and how they work simultaneously to produce output.

What is Control System?

Control system is combination of multiple devices that manages the command and directs the behavior of other systems, ensuring seamless operation. They are used in many fields like electronics, automation, manufacturing sectors and etc. The output in control system is govern by the input given to it and provides the desired response by controlling the output. Many components contribute to control system for its proper functioning and each of them has some specific function. The most common example of a control system is a traffic light system. As we all know how a traffic light system works seamlessly by providing the correct combination of output to control the traffic on the roads it’s a perfect example of how different components of traffic light work together to show the desired color of light at a particular time.

Control System

Types of Control System

There are two types of control systems:

- Open-loop control system.

- Closed-loop control system.

1. Open-Loop Control System

In this type of control system, the system responds without considering what the output is and doesn’t continuously monitor the system’s behavior. They are used in the systems where the output is already known and predictable so that there were no errors in the system in the future. The controller in the system sends commands to the plant without receiving feedback about the actual output and thus do not consider what is the output. They do not have complex design like closed-loop systems. Open-Loop Control System are used in applications where there is no feedback and error handling are required because they do not have feedback sensors and controllers to control the system and since there are no feedback to control the system, it often makes mistakes under changing conditions. They are used in system like electric bulb, micro-ovens, traffic signals and etc.

Open Loop Control System

2. Closed Loop Control System

In this type of system, the output is monitored continuously and can be adjusted whenever there is a need of it. The feedback mechanism helps to adapt to varying conditions and maintain the system in a stable state. They are used in voltage stabilizer, thermostat heater and etc. They have a very complex design as compared to open-loop control system.

.webp)

Closed Loop Control System

Components of Control System

There are some list of components of control systems given below :

- Plant

- Sensors

- Controllers

- Actuators

- Feedback

1. Plant

Physical system that produces desired output by regulating the output to accomplish a specific objective. It means something which can be controlled. The plant is designed in such a way that it can produce a certain output or perform a specific function. The output can be anything from specific motion in a mechanical system or a biological process. The entire plant can be viewed on a display in a GUI whereas custom-made software and GUI are also responsible for regulating the output of the plant to achieve specific objectives. For example, a DC motor is an example in which you can control mechanical aspect of the system like angular position, velocity and torque. Therefore, if something can be controlled can consider it as the plant in the control system.

Some of the common examples of plant are:

- Refrigerator,

- Speed control system,

- Boiler,

- steering system,

- Industrial process control

2. Sensors

Sensors or transducers are devices which convert physical changes like change in temperature, pressure and etc into electrical signals. Sensors provide feedback to controllers so that the process continuous and to reach the desired result. There are many types of sensors in a control system, and each have its own specific function. Example:

- Temperature sensor

- Pressure sensor

- light sensor

- Heat sensor

- Motion sensor

- Humidity sensor

- color sensor

.webp)

Sensor

3. Controllers

Controllers are used to control the behavior of dynamic system. They adjust themselves based on the feedback given to it. Controllers have fast response to errors but cannot remove steady-state error.

There are three types of controllers:

- Proportional Controller (P-Controller)

- Derivative Controller (D-Controller)

- Integral Controller (I-Controller)

The block diagram of control system helps us to understand the process more easily.

.webp)

Controller

The block diagram consists of five major components and function which contribute to control system.

- Input signal : Input signal represent the signal that the controller aims to regulate.

- Controller : The controller in the system is responsible for processing the error signal.

- System or process : The control output is applied to system or process that needs to be controlled.

- Feedback : The feedback is a process variable which is obtained from system.

- Output : Control output is the output signal generated by controller.

4. Actuators

Actuators are used to implement the actions which are determined by controller. They convert the control system received from controller into physical actions. After they receive signal from controller, they execute actions in the system. Actuators are used in automation, machines, in medical industry and automobiles. They play major role in a control system and work with the integration of sensors, controllers and other components of system.

.webp)

Actuators

There are five types of actuators based on power used:

- Hydraulic Actuators

- Pneumatic Actuators

- Electrical Actuators

- Magnetic Actuators

- Mechanical Actuators

Based on Type of motion there are two types of Actuators:

5. Feedback

The feedback loop connects the output of the plant from sensors to input of controller so that the controller can continuously adjust itself based on the signals from sensor. The error signal is crucial component in the feedback loop as it helps to guide the controller how to react and adjust accordingly. The error signal is difference between the desired setpoint and actual output. The closed loop feedback system helps to reduce disturbance and improve system’s stability. Ther can be two possibilities of feedback- positive feedback and negative feedback. Negative feedback helps to stabilize the system.

Advantages of Control System

- They are fast and error free : Control system have very fast response to the input, and they work faster than humans. They reduce the time and human effort in doing the same work. Control system make very minimal error while giving output, which makes it perfect in the jobs where there is a high risk of mistakes and errors. They subsequently reduce the error which humans can make easily because they are designed in such a way that they can operate with precision, leading to error free performance.

- Integration with other complex system : It integrate its function with other systems for better performance. This integration with other systems increases the capability of system and coordination provides perfection and productivity inside the system.

- Optimization : We can optimize the complex process into smaller different process and find the best operation to achieve the goal. It can be monitored and remotely controlled which is important aspect of control system and ensures error free performance, especially in task which are prone to high risk and mistakes.

Disadvantage of Control System

- Maintenance : Control systems require Maintenance on the regular basis to work properly. The maintenance also increases the cost factor which is a big disadvantage of a control system. Components like sensors and actuators are calibrated so that the efficiency of control system is maintained. Also to increase the life cycle of system they are updated and replaced with new technologies.

- Complexity : The designing of control system is difficult to understand and not everyone who is a beginner can figure out the functioning of very component in the system. Since the control system is composed of many different types of components, it is very challenging to control and implement task in it.

- Environmental Factor : The accumulation of waste due to its defected parts has serious environmental concerns. Therefore, proper disposal is necessary and recycling parts can be done to decrease environmental impact.

FAQs on Components of Control Systems

What is the role of feedback loop in control systems?

Closed loop adjust its actions in such a way that disturbance it not created in the system.

What is the role of actuator in control system?

They can implement the control actions which is determined by controller.

How does the controller impact the system stability?

The controllers are designed in such a way that they directly influence the stability of system.

Share your thoughts in the comments

Please Login to comment...