The RAC systems act as essential features of advanced societies since people prefer the ease and means to keep edibles fresh depending on cold storage services while industries need such operations to guarantee some produce quality. Indeed, at the heart of these systems are thermodynamic principles that facilitate heat transfer from one location to another; primarily between indoors and outdoors. In refrigeration systems, a substance called the ‘refrigerant’ circulates within a closed circuit alternately evaporating and condensing; absorbing heat during the process of evaporation and contributing it when in a state of conversion to liquid after becoming hot by absorption.

This cycle is carried out within a complex of components, namely the compressors, condensers, expansion valves, and evaporators. Through adjustment of the pressure and temperature, such as fridge air condition system bris-bane these systems can provide heat removing function to cool spaces or for special purposes like food storage, pharmaceuticals, chemicals processing, etc. Innovations in refrigeration and air-conditioning technology have made significant changes to various industries, modernizing cold storage for both transport functionality as well as available comfort within homes or offices. With the advancement of society, so will progress in the fridges and air conditioners which are essential to maintaining our modern life.

What is Refrigeration?

The process of cooling a space, substance, or system by removing heat from it is referred to as refrigeration. This is usually achieved through a process of evaporation and condensation in the form of refrigerant fluid. Refrigeration is essential for the storage of perishables, keeping indoor environments comfortable and covering a wide range of industrial processes. One of the most common kitchen appliances is a refrigerator, which uses the principle of cooling to preserve foods and drinks. It consists of several key components.

- Compressor: This part compresses the refrigerant gas, boosting its pressure and temperature.

- Condenser: The hot, high-pressure refrigerant gas is forced into the condenser coils, where it gives off heat to its surroundings and condenses back as a liquid under pressure.

- Expansion valve: The liquid refrigerant flows in through the expansion valve that decreases its pressure and temperature as it enters an evaporator.

- Evaporator: Low-pressure, rather low temperature liquid refrigerant evaporates to the gaseous state inside the fridge absorbing heat off from its interior is additionally cooled.

- Refrigerant: This fluid runs in a continuous loop around the system and transfers heat out from inside of the refrigerator to outside. The evaporation and condensation that take place in the system transfer heat from inside of refrigerator to outside, therefore maintaining much low temperature within.

The temperature of the refrigerator is adjusted by varying compressor operation which determines the flow rate and hence cool output. In brief, refrigeration is a mechanism that removes heat from the air or object to cool it down while making use of a fridge as an appliance in which one can keep foods and put drinks. In terms of refrigeration, it is the act or process in which heat from space and/or materials is drawn out to make its temperature lower.

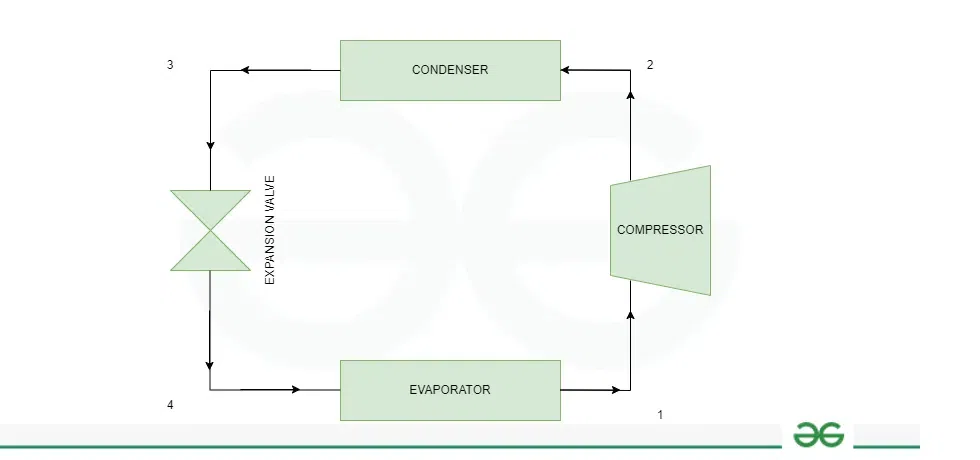

This process is achieved through the use of a refrigeration cycle, which typically involves the following components: the compressor, condenser expansion valve and evaporator. Here’s a simple diagram illustrating the refrigeration cycle:

Refrigeration

Working of Refrigerator

- The compressor is an acting variable that increases the pressure and temperature of refrigerant.

- The high pressure and hot refrigerants flow via the condenser coils where they become liquid, giving out heat into air.

- The liquid refrigerant flows into the expansion valve and is decreased in pressure by this process.

- The cold liquid refrigerant with low pressure flows through evaporator coils inside the wine fridge and absorbs heat from inside, causing it to vaporize.

- Thereafter, the gas refrigerant sucked back to a point of compression and this process continues.

- The repeated process of compression and condensation, expansion and evaporation keeps the refrigerator cold while extracting heat from whatever was stored there.

Refrigeration Cycle

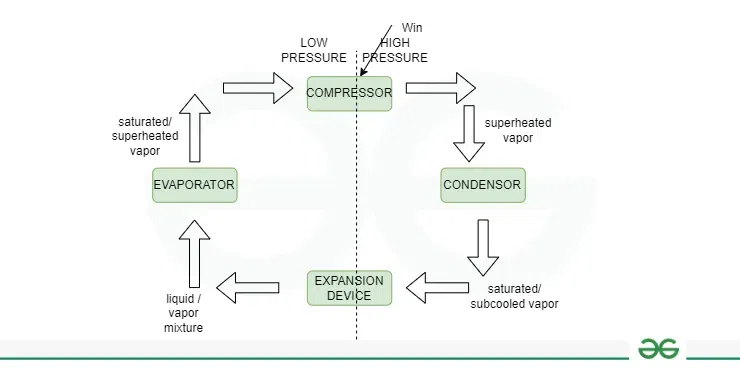

It cyclic processes heat away cooling spaces or the entities within such places either by way of conduction. One common cycle is the vapor compression cycle, which involves several steps:

- Compression: By being compressed, refrigerant gas becomes heated as a result of pressure and temperature.

- Condensation: In this, it is the gas that goes through a hot and high-pressure those condensers in condenser coil has to emit heat; which results into leaving very much of pressure liquid substance.

- Expansion: Loss of Time with the rise in valve high-pressure liquid refrigerant, its pressure decreases which leads to lowering of temperature.

- Evaporation: The low-pressure liquid line refrigerant is trapped in the evaporator coils where it absorbs both space or substance being cooled by entrapment and expansion.

The cyclic loop in refrigeration system makes it possible for the cycle to discharged heat from cold body or product hence lower his temperature. In such processes as that of the fridge, air conditioners and so on applications.

Refrigeration Life Cycle

Refrigerants

Refrigerants are chemicals which work by absorbing heat from inside the system and delivering it outside facilitating cooling process. They flow through the refrigeration cycle changing from liquid to gas formworks as a communicator of heat in that system.

Types of Refrigerants

There are several types of refrigerants, each with its own characteristics and environmental impact:

- Chlorofluorocarbons (CFCs): CFCs have been widely used as the refrigerant; it was known to document for its good performance characteristics in time past. Yet, they were proven to be major contributors in eating away the Ozone layer and practically phased out of use.

- Hydrochlorofluorocarbons (HCFCs): HCFCs were developed as substitutes to CFCs which have a lower atomic. They do less damage to the ozone layer but contribute still equally towards global warming thus becoming a relic under international treaty.

- Hydrofluorocarbons (HFCs): In recent years, the most common refrigerants are HFCs as their ozone depletion potential is rather insignificant. Yet they are highly intendable, contributes to the climate change. Measures are being taken to move away from HFCs to more eco-friendly substitutes.

- Hydrocarbons (HCs): Hydrocarbons like propane, or R-290, and isobutene as well referred to as R-600a are some of the natural refrigerants with low GWP values ranging between 1G WP/Kg per kg CO z mole; ozone depletion potential zero. Not only are they very effective and eco-friendly products, but due to their flammability issues certain considerations regarding proper handling become inevitable.

- Ammonia (NH3): Ammonia is another natural refrigerant that has 0 from ozone depletion potential factor with low GWP coefficient. It has excellent thermodynamic properties and is one of the most utilized in industrial refrigeration systems. But its toxicity and flammability restricts it so that some can be applied for.

Every refrigerant has its pros in terms of the performance, environmental impact and convenience for processing operation with some cons that may come along. To be specific, the type of refrigerant selected depends on the particular application; regulatory constraints as well as environmental concerns.

Refrigerants Properties

- Thermodynamic Properties: A refrigeration cycle includes phase changes of the used materials – liquid or vapor. As a result, they transfer heat efficiently from one place where it is unwanted to another hotter region which represents an ideal location for its dissipated energy at lower temperatures than other surrounding points within this system that facilitates circulation processes required repeatedly throughout such process ends without requiring additional input power supplies beyond those needed The thermodynamic properties like specific heat, latent heat of vaporization and pressure-temperature relationships hence determine the characteristics performance for refrigerant.

- Chemical Stability: An ideal refrigerant must be chemically stable and should thermodynamically survive in temperature points encountered within the system without getting involved into chemical reactions. The stability condition guarantees long-term operational dependability and efficiency of the refrigerated system.

- Ozone Depletion Potential (ODP): Ozone-depleting substances (ODS), which include chlorofluorocarbons[CFCs] and hydrochlorofluorocarbons [HCFCs], have high (ODS) values in reference to ozone depletion. Refrigerants which are environmentally sound have effectively zero or minute to almost no DP value and thus do not render any negative impact on the stratospheric ozone.

- Global Warming Potential (GWP): GWP measures the global warming impact of a refrigerant over some period relative to that for carbon dioxide. GWP values for some refrigerants, such as R245fa and HFC 134a are relatively high causing a greater contribution to global warming. Hydrocarbons (HCs) and natural refrigerants are popular, primarily for low GWP.

- Flammability: Refrigerant selection is based on flammability safety consideration. Among other available refrigerants like hydrocarbons with compounds such as propane and isobutane – are basically very highly flammable; therefore, in their design, installation & operation certain precautions must be taken. Namely, refrigerants that do not burn out or slightly combustible one’s such as HFCs and CO2 provide safer substitutes in certain uses.

Components of Refrigeration Systems

here are the key components of a refrigeration system along with explanations for each: on the top first third to understand all of them and then go downwards.

.webp)

Refrigeration System

- Compressor: Hoping to the refrigeration system this compressor, therefore is a heart. Compression is done with the intention to reduce refrigerant so that it can pass over other parts of vice while in form of high-pressure, hot gas. This increases the pressure and temperature of refrigerant leading to heat release on arrival at a condenser.

- Condenser: The condenser is a heat exchange system which will use compressed hot high-pressure refrigerant gas and cool it down by changing them into the pressure liquefaction above normal. The heat thus liberated passes into air or water surrounding it as the result of which actually transpires to condense.

- Expansion Valve: The expansion valve controls the flow of refrigerant from pressure and temperature into evaporator coils. This leads to the introduction of high-pressure liquid refrigerant which is expanding very quickly into low temperature and pressure that are commencing in to evaporator.

- Evaporator: Evaporator is the referral to yet another heat exchanger that may contain inside in case of a refrigeration space or substance. From the evaporator coils, low temperature and pressure liquid refrigerant gas is withdrawn here come the condenser where it takes heat which increases its other end form of high-pressure gaseous refrigerants. The refrigeration cooling results in a temperature reduction of the space or material undergoing such process.

- Refrigerant: The refrigerant that is flowing through the whole stages of a cooling system and which absorbs heat to give it out by discharging this cycle heats can be termed as working fluid. Along its course at every point of the compressor, condenser evaporator and expansion valve it goes through phase changes (liquid to gas).

What is Air Conditioning System ?

The various air conditioning systems are critical in creating survivable environments through monitoring temperature, humidity and quality of the air. All these systems utilize machines and techniques to produce cooling as well the drying effects. Air conditioning units function based on law of refrigeration where the behavior of physical state changes depending on whether it absorbs or releases heat. The main parts of an air conditioner system are the evaporator, compressor, condenser capacity estimates refrigerant and expense valve.

The evaporator, which is mostly placed indoor or in the air handling unit acts as a heat exchange. The warm air trapped inside the room with no refrigeration passes over extremely cold coils storing absolutely sub-zero temperatures to which heat is absorbed by vibrating molecules of super cool liquid and goes through phase change called evaporation making it go back into vapor state losing its negative impact on Earth’s surface temperature. At the same time, in most cases located outside of unit with compressor which cycles through refrigerant for circulation throughout that system. It scores the low-pressure, less – temperature refrigerant vapor into a high pressure and High Temperature gas which is ready to process condensation.

The refrigerant acting as a working fluid during this process passes through the system. It takes up heat from the air in an indoor environment through the evaporator, gives off heat into a surrounding area outdoors using condenser, changes phases becoming liquid and gas as well it undergoes phase transitions going via compressor –compressing vapors; condenser –– circulatory cooling of returning composition to high temperature by way heavy steam .

Air Conditioning System

Types of AC systems

Different types of air conditioning systems are available and designed for specific purposes are as follows:

- Window Air conditioner

- Split Air conditioner

- Central air conditioning system

Window Air Conditioner

A single window air conditioning unit comprises a front grille that draws in the cooling bank, a navigation panel to adjust temperatures and fan speed level as well as ducts for outlet of the current. At the inside it has expulsion coils, compressor and condenser wraps up consolidated in one housing and this air conditioner system works in the flow: The window air conditioners are a single unit fixed through the wall or wholly on a window. They have all parts incorporated in one compartment which includes the compressor, condenser, expansion valve and evaporator coil. Inside air heated by the furnace warms units circulates is pass around evaporation coils where it gets cooled and returns back to surroundings. While the refrigerant absorbs heat, it is discharged to outside air in fact through condenser coils.

Window-Air-Conditioners

Split Air Conditioner

In the case of splitting air conditioners, their indoor unit usually hangs above a wall or ceiling to have the evaporating coils with its holding air handler and filter in it. The outside unit encloses the compressor, condenser coils and a fan. Indoor and outdoor units are also joined via copper tubing and electrical wiring.

There are two types of air conditioners which include split type; its main components being indoor unit and outdoor unit. The evaporator coils and the air handler are located in the indoor unit; meanwhile, a separate outdoor unit holds compressor and condenser part. Refrigerant flows the indoor and outdoor side through copper tubing. In the indoor unit, warm air from inside is introduced to it whereby when passes over evaporator coils gets cooled. Cooled air then continues to supply the room as heat absorbed from it with refrigerant is transmitted outside through outdoor equipment.

Split Air Conditioner

Central Air Conditioning System

The main component of a central air conditioning system is the compressor, condenser coils and evaporator coils which are all contained within its centrally located unit. It is usually a standalone room for machinery or placed outside. Ducts take cold air to different rooms or zones by the supply vents and return warm supplied air within a building system through various retrofit ductwork installed in residential buildings.

Air conditioning systems used in central air to cool entire buildings or large spaces. These are made of a centralized cooling element that is generally mounted external to the interiors which is linked with several ducts and channels these pipes or tubes channel fresh cold air into various rooms or regions. The central unit consist of a compressor, condenser and evaporator coils with duct work from which cool air continuously delivered through out the home. All warm air is sucked back into the unit for cooling as it enters in to room return vents throughout your house.

Central Air Conditional System

Heat Exchangers

The heat exchangers are built to accomplish the operation of transferring from one fluid (liquid or a gaseous material ) through another liquid without the fluids being in contact. They have industrial practice in process, HVAC system refrigeration and power generation. The fundamental principle of heat exchangers is that thermal energy flows from a hot fluid to another colder one through an obstacle – it may be a solid (in certain constructs) or liquid, similar as in direct contacting. This goal is to develop optimum heat transfer, whilst minimizing energy losses and keeping the fluids intact.

Here’s how a typical heat exchanger works:

- Fluid Circulation: The two working fluids that are engaged in the heat transfer process pass on through different paths or ducts present inside of the drawn out exchanger. On one side of the exchanger, there is a fluid that flows on it while on another opposite side; an alternative different type of fluids flow side by side. Parallel or crossed passing in these sections are dependent on the design.

- Thermal Contact: With the fluids going through their different channels, they approach close to the heat exchange surface. This interface is conventionally crafted from a thermal material, like metal, with the intent of ensuring ease in heat transference.

Heat Transfer: The hot fluid transfers its energy through the heat exchange surface to the cooler fluid. This transfer is arising with the difference in temperature between two types of fluids and conductive properties of a material separating them. As the warm liquid transfers thermal energy, this decreases its temperature whereas cold fluid receives heat thus increasing it.

- Temperature Equalization: The process continues until either the difference between temperatures of two fluids reduces to a level where equilibrium is reached or when design criteria are followed. The objective is to attain the specified temperature of output fluid streams.

Application of Refrigeration and Air Conditioning

Although the underlying principle of refrigeration and mainstream air conditioning technologies is based on a common formula, their practical uses are poles apart in the sectoral perspective – from households to commercial objects passing by facilities meant for industrial use with advanced scientific principles. Here are some specific applications:

1. Food Preservation and Storage

- Uses of refrigeration in food industry Applications include.

- Bulk handling facilities for chilling, freezing and cold storage of raw materials, additives and final products.

- In public locations such as restaurants, cafeterias and other commercial kitchens walk – in ref can be for refrigerators , freezers also ice machines.

2. HVAC Systems for Buildings

- Because of this, it air conditioning and heating is used in homes or places which can either be business areas or offices as well other institutes for example schools.

- The steady comfort cooling and heating for temperature control in the indoor air its humidity content.

- Ventilation that will provide adequate fresh air and remove contaminants indoors.

- Energy conserving from the progress of modern HVAC technologies, including VRF systems and some type thermostat.

3. Medical and Pharmaceutical Applications

- Cryogenics is critical to Store vaccines; drugs and biological materials accordingly at recommended temperatures to prevent product inactivation or spoilage.

- Laboratory equipment including ultra-low temperature freezers and cryogenic storage system used for research or clinical trials.

4. Data Center Cooling

- Air conditioning systems are required in the Maintaining cool server rooms and data centers to remove heat generated from computer servers as well electronic equipment, maintaining proper operation conditions.

- The need for proper temperature and humidity control, thus ensuring that the equipment gets neither too hot to cause damage.

5. Industrial Processes

Different industrial applications use refrigeration like:

- Industries that utilized petrochemical in cooling reactors, distillation columns and other related equipment.

- Stamping and mold casting, Lancing hot/cold rolling mills are used for controlling temperatures during welding machining heat treatment processes.

- Pharmaceutical manufacturing for temperature controlled storage and process active drugs ingredients.

Advantages and Disadvantages of Refrigeration and Air Conditioning

Apart from providing so many advantages, refrigeration and air conditioning systems also have some drawbacks. Let’s explore the advantages and disadvantages of these technologies:

Advantages

- Comfortable Indoor Environment: Comfortable temperatures and humidity levels achieved using passive type of air conditioning systems are preferred more by occupants in their homes, offices or business common areas.

- Preservation of Perishable Goods: Refrigeration systems keep perishable foods, pharmaceuticals and biological samples fresh by keeping the temperatures low reduce shelf life issues as well as curb spoilage of items.

- Temperature Control in Industrial Processes: Technologies associated with refrigeration are critical in regulating temperature a variety of the industry processes to ensure product quality, consistency and safety especially within sectors such as food processing for instance; chemical manufacturing industries and pharmaceutical.

- Energy Efficiency: The contemporary refrigeration systems and air conditioning appliances employ energy-saving technologies that include variable speed compressors, intelligent controls as well as a heat recovery mechanism since it minimizes their consumption level together with operation costs.

- Data Center Cooling: Air conditioning systems are one of the essential aspects in ensuring that data centers and server rooms stay cool enabling worker as well as equipment to remain at a steady low temperature.

Disadvantages

- Environmental Impact: HCFCs and HFCs are known refrigerants which when released into the atmosphere cause ozone depletion as well as global warming if used in conventional air conditioning systems.

- Energy Consumption: As energy conversion, refrigeration and air conditioning systems make great use of electricity which accelerates the greenhouse gas emission that leads to environmental degradation especially in fossil fuels driven regions.

- Maintenance Requirements: Refrigeration and air conditioning systems are maintained for making filter replacement, coil cleaning procedure besides refrigerant recharges as a norm to get the best results. Lack of maintenance will result to decreased efficiency and increased energy consumption hence breakdowns.

- Initial Cost: However, relatively high upfront cost associated with buying and setting up refrigeration or air-conditioning systems, more so when such include hi spec models dealers; useful add on features could represent another inherent deterrent if factored in the user’s budget.

- Noise and Aesthetic Considerations: Window units and some of he older models can produce noise when in operation, which may be uncomfortable to occupants. Moreover, in addition to the noise and other bothersome facts condenser units on building façades or even along streets visually discredit buildings as well as outdoor areas.

Difference Between Refrigeration and Air Conditioning

Here’s a comparison between refrigeration and air conditioning in tabular form:

Aspect

|

Refrigeration

|

Air Conditioning

|

|

Purpose

|

mostly as cooling facilities and refrigerators.

|

Primarily applied in areas where the dehumidifying and cooling of hot air is required within buildings to maintain temperature at a favorable level.

|

|

Application

|

The standard uses include refrigerators, freezers cold rooms, refrigerated trucks and industrial process such as food preservation pharmaceutical processing laboratories etc.

|

Used more often in the residential, business and industry for comfort cooling room conditioning.

|

|

Cooling Method

|

Refrigeration is defined as the process of cooling a limited environment or storage medium such as cold room and so on.

|

The process of cooling and circulating through hot air inside an enclosure, characterized by draw heat, moisture in a chamber called refrigerant.

|

|

Temperature Control

|

It keeps a low temperature to maintain product quality and shelf life of perishable goods.

|

It regulates the temperature to a pleasant level for occupants.

|

|

Humidity Control

|

Depending on some specific application to answer or not address the humidity control.

|

Usually the process of dehumidification that is aimed either at ensuring comfort or preventing any impact related to moisture.

|

|

System Components

|

With the exception of a few situations where it is usually made up by a compressor, vaporizers, condensers expansion valve and coolant.

|

Comprises of compressors, evaporators condensers expansion valves and refrigerants are like that of Refrigeration systems.

|

|

Environmental Impact

|

Refrigerants used and other forms of application with regards to the cooling systems may also result in ozone depletion alongside global warming.

|

Both refrigerants used in air conditioning systems could lead to global warming as well the depletion of ozone layer however there are newer and environmentally friendly coolant being developed.

|

|

Maintenance Requirements

|

Has to be kept up with on a regular basis in order to stay at its optimum.

|

Need regular cleaning to improve performance, energy efficiency and indoor air quality.

|

|

Energy Consumption

|

Energy needed to maintain the low temperatures and preserve perishable products of quality.

|

Energy required to cool and dehumidify the air, with energy used also dependent on system efficiency as well as operating conditions.

|

|

Cost

|

Primary cost may be very high due to specialized tools and installation restrictions.

|

Upfront cost depends upon the system type, size, and its complexity fluctuate between moderate to high.

|

Conclusion

To conclude, refrigeration and air conditioning technologies are crucial in contemporary civilization although they serve different roles. Air conditioning systems are needed because they make indoor places more comfortable either at home or office as well business premises across various industries since modernization sets down that cooling air using these devices Though these two technologies vary in some aspects, they use the same components and need regular maintenance to achieve maximum results. Nevertheless, these systems also pose environmental risks because the refrigerants used by them subject ozone depletion and greenhouse effect. Measures to implement energy efficient technologies and work towards finding more environmentally sound refrigerants are vital in coping with this type of impact. In conclusion, although refrigeration and air conditioning systems provide many advantages in luxury life comfortably conveniently conserved chemical substance preservations foodstuff saving theirs environment economic social feet therefore it is necessary to study deep its influences by around.

FAQs on Refrigeration and Air Conditioning

What are the impacts of refrigerants in refrigeration and air conditioning systems on environmental ?

Major emitters of HCFCs and HFCs including older cooling systems have been implicated in ozone depletion and global warming. This has resulted in global programs aimed at phasing out these compounds under agreements such as the Montreal Protocol. Developments in refrigerants with lower environmental impact, such as (HFOs) and the like include natural coolant ammonia and carbon dioxide.

What role do refrigeration and air conditioning systems play in energy consumption as well the issue of climate change ?

Electricity used in refrigeration and air-conditioning systems is particularly high especially where majority of energy sources are from fossil fuel. This also adds to the greenhouse gas emissions and intensifies climate change. The positive effects can be achieved with the use of energy-efficient technologies, improved system design and utilization renewable sources.

What new trends and innovations are we seeing in refrigeration and air conditioning technology ?

New trends observed in the industry are energy efficient systems, heat pump technology both heating and cooling applications; natural refrigerants to reduce climate change. Other innovations are integration of smart controls and automation to enhance performance that takes care of sustainable cooling solutions for off-grid as well as remote areas. What’s more, cooling methods in passive refrigeration technologies and thermal storage systems are also conducted for better efficiency and effectiveness.

Share your thoughts in the comments

Please Login to comment...