Difference Between DC Series Motor and Shunt Motor

Last Updated :

27 Feb, 2024

DC Series Motor and DC Shunt Motor form an integral part of the modern-day electronics industry. We know that there are two types of motors that can be used to convert electrical energy into mechanical energy. While one uses AC for it, the other uses DC for it.

In this article, we will study the motor that uses DC to convert electrical energy into mechanical energy. Even when dealing with DC motors, we can divide them into certain types like Series DC Motor, Shunt/Parallel DC Motor, Compound DC Motors, and Permanent Magnet DC Motor.

In this article, we will focus on Series DC Motor and Shunt DC Motor. We will see the construction and working of each of these types of DC motors and we will try to analyze the differences between the two. After comparing their work, we will study the Advantages and Disadvantages of the two types of motors.

Later we will study which applications require which kind of motor. The article concludes with some frequently asked questions that readers can refer to.

What is a DC Series Motor?

Typically a DC Motor is a motor that works on direct current supply. A DC motor is made up of two main parts namely, magnetic field system and an armature. Now when we talk about DC Series Motor, it is the motor where the armature winding and the field winding are connected in series. Basically, it gets the name series motor because of the placement of components in this kind of motor. To understand it better let us see the construction and operation of DC Series Motor.

Construction of DC Series Motor

Here is the circuit diagram of DC Series Motor.

DC Series Motor

In this circuit we can see how the armature winding is placed in series with respect to field winding. The basic circuit construction includes a DC power source which will produce DC current, a series field and an armature which is connected in series through a wire. This is the construction of DC Series Motor. The armature is important since it interacts with the magnetic field to produce energy.

Operation of DC Series Motor

To understand the working of DC Series Motor, see that the armature and the winding are placed in series. Initially the DC motor is turned on and power flows through both armature and winding. Due to the series circuit, we can say that the current flowing in field winding is equal to the armature current. This is based on the properties of series circuit. When current flowing through armature passes in the field winding, it generates an electric field . This is based on the law that any current carrying conductor will generate magnetic field around it.

This generated magnetic field then interacts with the current-carrying conductors in the armature. The interaction between the armature and magnetic field generates a mechanical torque which results in the rotation of the rotor. The direction of this torque can be calculated using Fleming’s left-hand rule. Note that the direction of the torque is such that it tries to match armature’s magnetic field and the magnetic field of field winding. This is how mechanical energy is generated form electrical energy.

What is a DC Shunt Motor?

Typically a DC Motor is a motor that works on direct current supply. A DC motor is made up of two main parts namely, magnetic field system and an armature. Now when we talk about DC Shunt Motor, it is the motor where the armature winding and the field winding are connected in parallel. Basically, it gets the name shunt motor because of the placement of components in this kind of motor. To understand it better let us see the construction and operation of DC Shunt Motor.

Construction of DC Shunt Motor

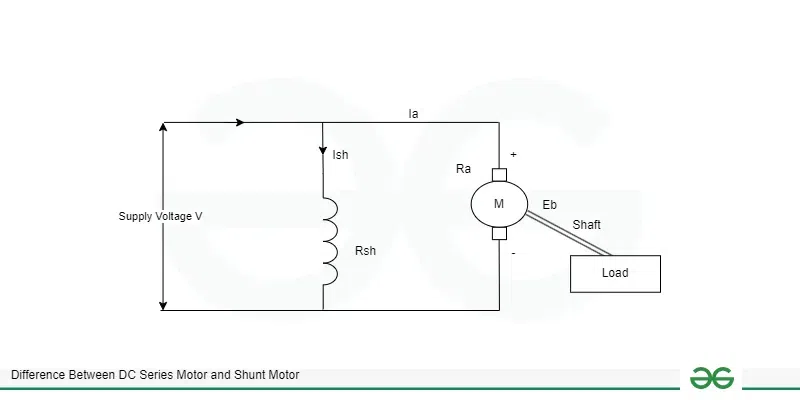

Here is the circuit diagram of DC Shunt Motor

DC Shunt Motor

In this circuit we can see how the armature winding is placed in parallel with respect to field winding. The basic circuit construction includes a DC power source which will produce DC current, a winding field and an armature which is connected in parallel through a wire. Not that the shunt field winding has comparatively a large number of turns with high resistance compared to the armature winding. This is the construction of DC Shunt Motor. The armature is important since it interacts with the magnetic field to produce energy.

Operation of DC Shunt Motor

To understand the working of DC Shunt Motor, see that the armature and the winding are placed in parallel. Initially the DC motor is turned on and power flows through both armature and winding. Due to the parallel circuit, we can say that the voltage developed in field winding is equal to the armature voltage. This is based on the properties of parallel circuit. Voltage and current across the shunt winding remains constant due to which DC shunt motor operates at constant speed. Now the current splits between the armature and the winding in a way that voltage developed across both of them remains same. Due to this current in shunt field ,a constant magnetic field is generated which remain unaffected by the armature current.

This generated magnetic field then interacts with the current-carrying conductors in the armature. The interaction between the armature and magnetic field generates a mechanical torque which results in the rotation of the rotor. The direction of this torque can be calculated using Fleming’s left-hand rule. Note that the direction of the torque is such that it tries to match armature’s magnetic field and the magnetic field of field winding. This is how mechanical energy is generated form electrical energy.

Advantages of DC Motor

Let us see some advantages of DC motor :

- The presence of high shunt resistance in DC shunt motor gives us the direct control of the speed of motor by controlling the current in the field. This feature is known as speed regulation.

- The torque generated by DC shunt motor is linear in nature which makes it easier for us to predict and stabilize the torque generated by DC shunt motor.

- The torque generated by DC series motor is non-linear in nature which makes the starting torque generated by it quite high and produce large rotations.

- Dc motor offers a quick and wide range of control operation, it has fast operations like quick starting, stopping, reversing, and fast acceleration. This is a unique feature.

- DC motor becomes best choice for driving heavy loads. Due to its ability to change electrical energy to mechanical energy ,it is used for driving purposes.

Disadvantages of DC Motor

Let us see some disadvantages of DC motor :

- The installation charges of DC motor is very high meaning that it raises the initial cost of production due to different components.

- The component like brushes and commutators require high maintenance meaning that even after installation , you have to spend a lot of money on the maintenance.

- Care need to be taken because working with DC motors can lead to mishaps that occur due to sparking at brush DC motors. These can lead to explosions.

- After a certain amount of time ,the armature begins to get destroyed which is mainly because of the vibrations in the shaft due to increased speed.

- The mechanical energy of rotating DC motor can’t be accessed directly and some conversion device like a convertor is needed for accessing the energy produces.

Applications of DC Motor

Let us see some Applications of DC motor :

- In case of applications that require high starting torque, we use DC series motors. This include domains like electric locomotives, hoists , cranes, electric bikes and cars, etc.

- In case of applications that require constant speed, we use DC shunt motors. This include domains like fans, blowers, elevators, centrifugal pumps, lath machines, etc.

- In general any electronics task which requires conversion of electrical energy into mechanical energy, DC motor is the first choice.

- The major use of using DC motor is in conveyors where it ensure that its starting torque is five times more efficient than rated torque. These conveyer belts are then used in industries, factories , markets.

- Another major use of using DC motor is in high speed elevators. AC motors can’t be used in elevators because they are difficult to decelerate and accurately making DC motor the best choice.

Difference Between DC Series Motor and Shunt Motor

Let us compare DC Series Motor and DC Shunt Motor

|

Parameter

|

DC Series Motor

|

DC Shunt Motor

|

|

Field winding arrangement

|

Field is in series orientation with respect to armature.

|

Field is in parallel orientation with respect to armature.

|

|

Starter

|

It uses a 4 point starter.

|

It uses a 3 point starter.

|

|

Construction

|

Dc Series Motor |

Dc Shunt motor |

|

Torque magnitude

|

High

|

Low

|

|

Field Current

|

Field current is same.

|

Field current is not necessarily same.

|

|

Staring torque

|

High starting torque.

|

starting torque is not as high as series motor.

|

|

Starting current

|

High starting current due to combined field and armature winding in series.

|

Small starting current due to high resistance.

|

|

Speed-load characteristics

|

Speed is not constant

|

Constant speed

|

|

Speed regulation

|

The speed regulation is good around 10%.

|

The speed regulation is less than 10%.

|

|

Torque-current relation

|

Torque increases as the square of armature current.

|

Torque is directly proportional to armature current.

|

|

Resistance of field winding

|

Low resistance

|

Very high resistance

|

|

Voltage developed

|

Voltage across armature and field windings is not necessarily same.

|

Voltage across armature and field windings is same.

|

|

Dynamic response

|

It has a faster dynamic response.

|

It has a slower dynamic response.

|

|

Rotor design

|

Rotor is designed for high starting torque.

|

Rotor is designed for high constant speed.

|

|

Field current adjustment

|

It has same field and armature currents so no current adjustment allowed.

|

Current adjustment allowed without changing armature current.

|

|

Need of load balancing mechanism

|

It requires a load balancing mechanism to prevent over-speeding.

|

It doesn’t require load balancing mechanism due to constant speed.

|

|

Energy efficiency

|

Low energy efficiency

|

Better energy efficiency

|

|

Uses

|

Electric trains, cranes, conveyer belt

|

machine tool, printing, paper machine.

|

Conclusion

We have seen how there are different methods of converting electrical energy to mechanical energy using DC current. We also saw that using shunt motor and series motor are two of the many methods. Although both of these methods vary in construction and working yet both are responsible for performing one basic task that is conversion of electrical energy to mechanical energy. Depending on the type of work being done, we can decide any one of the to circuits to achieve the task . It is important to identify which type of motor will work better in which case. This can be done by understanding the applications of each type of motor. Readers are advised to go through the construction and working of the motors carefully to ensure proper clarification of the topic. You can refer to the frequently asked questions in-case of any doubt.

FAQs on Difference Between DC Series Motor and Shunt Motor

What is rotor in a DC motor?

The rotating part of DC motor is called rotor, due to its metallic nature it experiences a torque when exposed to magnetic field therefore it converts electrical energy to mechanical energy through rotations.

Why is the resistance of shunt field relatively high resistance compared to the armature winding in DC shunt motor?

The reason that shunt field has high resistance is because shunt field winding needs to produce a constant magnetic field in the motor, which is essential for stable working of motor this is only possible when it has higher resistance than armature.

What are some other types of DC motor?

Some other types of DC motors include Stepper Motor, Hysteresis Motor, Servo Motor, Brushless DC Motor (BLDC) and Permanent Magnet DC Motor.

Share your thoughts in the comments

Please Login to comment...