Difference Between BLDC Motor and PMSM Motor

Last Updated :

27 Feb, 2024

BLDC Motor and PMSM Motor form an integral part of the modern-day electronics industry. We know that two types of motors can be used to convert electrical energy into mechanical energy. We talk about these motors when referring to automotive motors. In this article, we will study the motor that uses DC and AC to convert electrical energy into mechanical energy.

Even when dealing with DC motors, we can divide them into certain types like Brushless Direct Current Motor, DC shunt motors, DC series motors, and AC motors like Permanent Magnet Synchronous Motor Motor. In this article, we will focus on Brushless Direct Current Motor and Permanent Magnet Synchronous Motors. We will see the construction and working of each of these types of motors and we will try to analyze the differences between the two. After comparing their work, we will study the Advantages and Disadvantages of the two types of motors.

What is a BLDC Motor?

BLDC motor stands for Brushless Direct Current Motor. Typically a DC Motor is a motor that works on a direct current supply. A DC motor is made up of different major parts namely, magnetic field system and rotors. Now when we talk about BLDC Motor which is a type of DC motor. This motor is characterized by the absence of brush assembly for performing commutation. Basically, it uses an electronic commutation system for performing the operations. To understand it better let us see the construction and operation of BLDC Motor.

Construction of BLDC Motor

Here is the circuit diagram of BLDC Motor.

BLDC Motor

In this circuit we can see how it is made up of stator and rotor. The basic circuit construction includes a DC power source which will produce DC current, the stator which is the stationary part has windings attached to it. The control circuit is connected to stator part which is used for exciting it and then there comes a rotor which is the rotating part made up of magnets. This is the construction of BLDC Motor. The rotor is important since it aligns with the stator to produce energy.

Operation of BLDC Motor

To understand the working of BLDC Motor, see that the stator is initially stationary and rotor is stable. Initially the DC motor is turned on and power flows to the stator part of the circuit. Due to this the stator gets excited due to the flow of energy. After this, the rotor which is made up of magnets gets influenced by the magnetic field of stator.

This generated magnetic field then interacts with the magnets in the rotor. The interaction between the rotor and and stator magnet makes the rotator align with the stator windings. When the rotor gets aligned with stator magnet, the next winding of stator gets excited. This continuous cycle is created due to which the rotor begins rotating. The electronic control circuit used in the BLDC motor is responsible for generating unidirectional torque. The direction of this rotation can be calculated using certain laws of electromagnetics. This is how mechanical energy is generated form electrical energy.

What is a PMSM Motor?

PMSM stands for Permanent Magnet Synchronous Motor. Typically an AC Motor is a more complicated motor that works on alternating current supply. An AC motor is made up of different major parts namely, magnetic field system and permanent magnets which help in field generation. Now when we talk about PMSM Motor which is a type of AC motor. It is a motor that is characterized by its use of permanent magnets to provide the necessary field excitation and thereby generate electricity. To understand it better let us see the construction and operation of PMSM Motor.

Construction of PMSM Motor

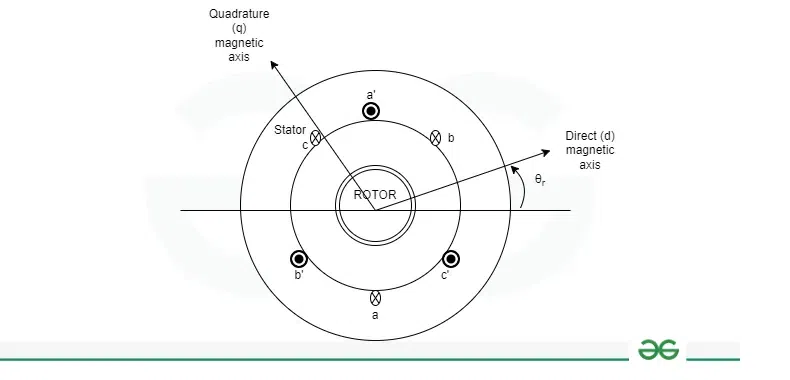

Here is the circuit diagram of PMSM Motor

PMSM motor

In this circuit we can see how it is made up of stator and rotor. The basic circuit construction includes a AC power source which will produce AC current, the stator which is the stationary part has windings attached to it. We see that the motor also has some permanent magnets attached to it. Apart from the stator and permanent magnets PMSM has some rotors responsible for performing rotations. This is the construction of AC PMSM Motor. The rotor is important since it aligns with the stator to produce energy. Note that the AC power supply is necessary because this motor is not self-starting.

Operation of PMSM Motor

To understand the working of PMSM Motor, see that the stator is initially stationary and rotor is stable. Initially when the AC motor is turned on, the AC power supply is switched on and power flows to the stator part of the circuit. Due to this the stator gets excited due to the flow of energy. After this, the rotor which is made up of magnets gets influenced by the magnetic field of stator. This can be seen by the setting rotating magnetic field which is developed in the air gap between the stator and rotor.

This generated magnetic field then interacts with the magnets in the rotor. The interaction between the rotor and and stator magnet makes the rotator align with the stator windings. Eventually the poles of rotor magnet align with the rotating magnetic field of the stator and starts rotating at the synchronous speed. When the rotor gets aligned with stator magnet, the next winding of stator gets excited. This continuous cycle is created due to which the rotor begins rotating. The direction of this rotation can be calculated using certain laws of electromagnetics. This is how mechanical energy is generated form electrical energy.

Difference Between BLDC Motor and PMSM Motor

Let us compare BLDC Motor and PMSM Motor

|

Parameter

|

BLDC Motor

|

PMSM Motor

|

|

Name

|

Brushless Direct Current Motor

|

Permanent Magnet Synchronous Motor

|

|

Type

|

DC motor

|

AC synchronous motor

|

|

Description

|

A DC motor which does not have carbon brushes and commutator assembly.

|

AC synchronous motor that uses permanent magnets to provide the necessary field excitation.

|

|

Torque

|

Lower torque than PMSM motor.

|

Has higher torque than BLDC motor.

|

|

Efficiency

|

Less efficient (Around 85% to 90%)

|

More efficient (around 92% to 97%)

|

|

Switching losses

|

high core losses because of harmonics.

|

Less due to less harmonic content.

|

|

Torque ripple

|

Present

|

Absent

|

|

Control

|

Uses simple control algorithms.

|

Uses complex and mathematically intensive controls.

|

|

Cost

|

less expensive.

|

More expensive.

|

|

Uses

|

Used in hard drives, CD/DVD drives, washing machines, fans, pumps, robotics, etc

|

Used in servo drives, traction control, robotics, aerospace, power factor improvement, machine tools, etc.

|

Advantages

Let us see some advantages of BLDC Motor and PMSM Motor :

- BLDC motor is better form of DC motor due to absence of brushes. BLDC Motor has high efficiency as compared to conventional DC motor.

- The BLDC motor is safer and has less hazards associated with it due to absence of brushes. This means there is no sparking due to absence of brushes.

- BLDC motor offers a quick and wide range of control operation, it has fast operations. In addition to it ,it is more reliable and long-term adding on to its unique features.

- PMSM motor offers wide range of advantages like it has high efficiency, it is compact in size. It also has a permanent magnet rotor offering higher torque with smaller frame size and no rotor current

- PMSM motor becomes best choice for driving heavy loads. It has extremely high dynamic performance making it a better choice than other motors.

Disadvantages

Let us see some disadvantages of BLDC Motor and PMSM Motor :

- The installation charges of BLDC and PMSM motor is very high meaning that it raises the initial cost of production due to different components like permanent magnets.

- The component like brushes and rotors in BLDC motor requires high maintenance and cautiousness. There is a particular range of operation of these motors because rotors operate on a temperature limit due to the magnets .

- The power requirement of BLDC motor is very high. Brushless motors require an electronic controller which requires additional power which can reduce the overall efficiency.

- The PMSM motor uses permanent magnet. These motors undergo irreversible magnetization due to changes in temperature which can be a major disadvantage.

- The controlling of PMSM motor is difficult as compared to other motors. The managing of whole motor requires a complex control system, including power electronics and microcontrollers.

Applications

Let us see some Applications of BLDC Motor and PMSM Motor:

- In case of applications that require varying load, we use DC motors like BLDC. This include domains like hard drives, CD/DVD drives, washing machines, fans, pumps, robotics, etc.

- In case of applications that require permanent magnets we use PMSM Motor. This include domains like servo drives, traction control, robotics, aerospace, power factor improvement, machine tools, etc.

- In general any electronics task which requires conversion of electrical energy into mechanical energy, BLDC motor and PMSM are a choice.

- The major use of using BLDC motor is in fields of industrial control, automotive, aviation, automation systems, health care equipment’s where it performs tasks efficiently

- Major use of using PMSM Motor motor is in the metallurgical industry, ceramic industry , rubber industry , petroleum industry, textile industry and even some low voltage machinery.

Conclusion

We have seen how there are different methods of converting electrical energy to mechanical energy using DC current and AC current. We also saw that using BLDC Motor and PMSM Motor are two of the many methods. Although both of these methods vary in construction and working yet both are responsible for performing one basic task that is conversion of electrical energy to mechanical energy.

Depending on the type of work being done, we can decide any one of the to circuits to achieve the task . It is important to identify which type of motor will work better in which case. This can be done by understanding the applications of each type of motor. Readers are advised to go through the construction and working of the motors carefully to ensure proper clarification of the topic. You can refer to the frequently asked questions in-case of any doubt.

FAQs on Difference Between BLDC Motor and PMSM Motor

What is rotor in a motor and why is it necessary?

The rotating part of DC motor is called rotor, due to its metallic nature it experiences a torque when exposed to magnetic field therefore it converts electrical energy to mechanical energy through rotations.

Why do we need to provide an additional variable power supply to PMSM motor?

The reason that PMSM motor requires an additional power supply is that it is not self-starting. It needs a variable frequency power supply for getting started.

What are some other types of DC motor?

Some other types of DC motors include Stepper Motor, Hysteresis Motor, Servo Motor, DC shunt motor and DC series Motor .

Share your thoughts in the comments

Please Login to comment...