A perfect weld is essentially unachievable in practice, and most of the time it is not necessary to give the requisite level of service functions. As a result, in order to define what is appropriate and suitable for use, numerous industries have set standards and tolerances for welds. These allow for different kinds, sizes, and frequencies of flaws and are described as codes or standards.

The identical weld may be permitted under one code but not under another because some rules are more stringent than others. Weld surface irregularities, discontinuities, flaws, or inconsistencies that appear in welded objects are referred to as welding defects. Weld joint flaws may cause assemblies and parts to be rejected, expensive repairs to be made, a major decrease in performance under working conditions, and, in the worst situations, catastrophic breakdowns that cause property and human casualties.

These flaws have multiple root causes. The majority of the time, poor weld design, inappropriate welding techniques, and the use of incompatible materials lead to flaws. These flaws can also be caused by inadequate welder training, shoddy workmanship, and a lack of process expertise. Furthermore, because of the inherent weaknesses in welding technology and the properties of metals, there are always certain faults in the welding.

Welding Defects

A bad weld weakens the joint and causes a weld fault. It is described as the welding process’s point beyond allowable tolerance. Dimensional flaws could occur, leading to an inadequate outcome. They could also occur in the form of material qualities or discontinuities. Incorrect welding patterns, material selection, skill, or machine parameters, such as welding speed, current, and voltage, are common reasons of welding faults.

Defects in welding

External Welding Defects

Any discontinuities in the weld metal that are visible to the unaided eye are referred to as external welding errors.

External welding are of different types :

- Cracks

- Porosity

- Undercut

- Overlap

- Burn Through

- Spatter

- Underfilled

- Excess Reinforcement

- Mechanical Damage

- Distortion

- Misalignment

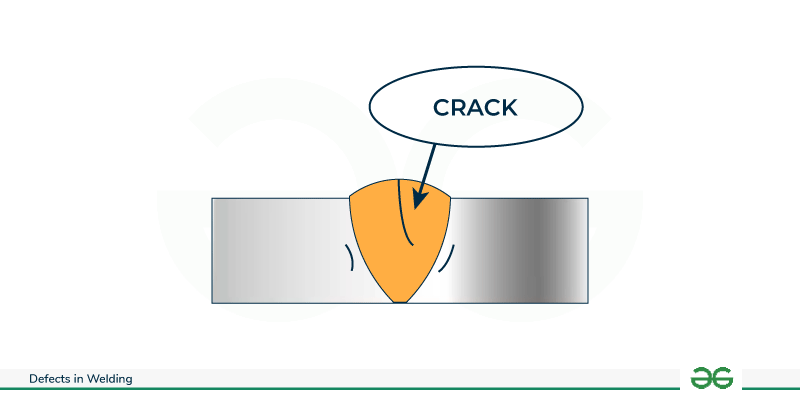

Cracks

The worst kind of welding flaw is a crack since it can spread quickly to get larger and eventually cause failure. The way that weld cracks originate in the weld bead determines how they are primarily categorized.

We have two types of crack :

- Hot cracks : It will be created when parent and base metals are heated above 10,000°C and the weld joints crystallize. The two main causes of hot cracks are using the wrong filler metal and subjecting the workpieces to rapid heating and cooling during procedures like laser welding.

- Cold cracks : It follows the weld metal’s cooling process, cold fractures appear. Days or even hours may pass after the metal cools before the weld break appears.

Causes of Cracks

- The expansion and contraction of the metal.

- Ductile base metal.

- The application of residual stress.

- Sulphur and Carbon.

Prevention of Cracks

- Preheating the metals.

- Cooling the joint of weld.

- Maintaining acceptable gaps between weld joint.

Crack Defect

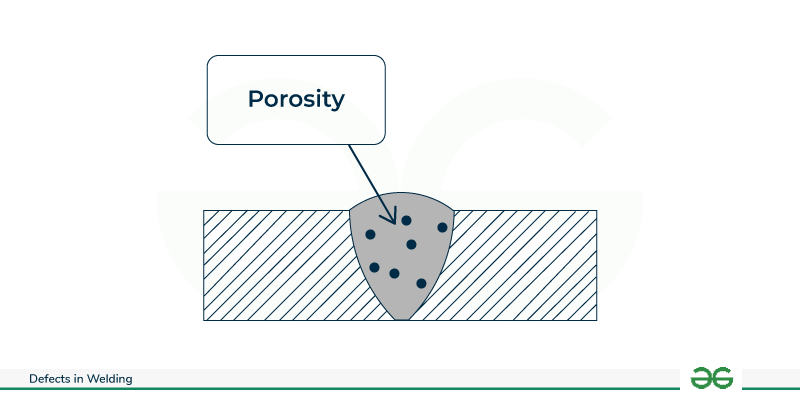

Porosity

The creation of holes in the weld pool as a result of trapped gas bubbles is known as porosity. When employing shielding gas, which is a component of welding processes like TIG and stick welding, it is typically one of the most prevalent welding faults.

On the other hand, when big gas bubbles become trapped in the weld pool, extreme forms of porosity manifest as blow holes or pits. Smaller gas molecules may also mix with the welded metal to create an impure mixture.

Causes of Porosity

- Unclean welding surface.

- Wrong electrode selection.

- Lack or absence of shielding gas.

- Fast travel speed.

- Too high welding current.

Preventions of Porosity

- Cleaning the weld surface.

- Using correct welding electrode.

- By preheating the metals before welding.

- Adjustment of welding current.

- Travel speed setting.

Porosity defect

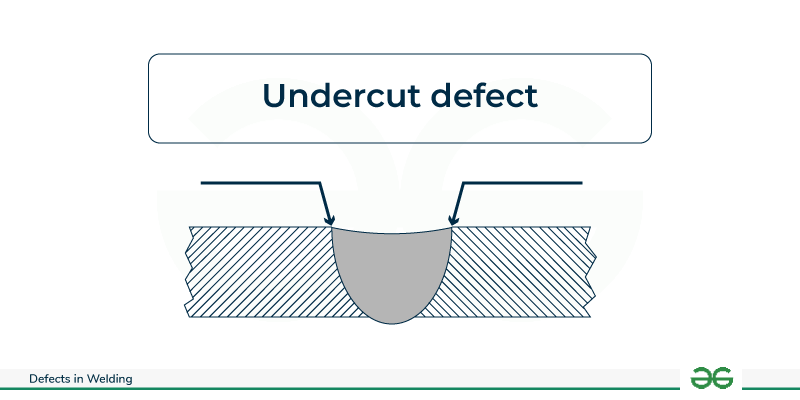

Undercut

There are two basic reasons why an undercut forms, though it can happen for other causes as well. The first involves employing too much current, which causes the joint’s edges to melt and leak into the weld. The second reason is that the weld does not have enough filler metal placed in it. As a result, the cross-section is reduced, resulting in notches or grooves along the weld that enhance stress when fatigue loading is applied to the material. This flaw appears at the weld’s toe or, in the event of many runs of welding, at the fusion face. Inter-run, intermediate, and continuous runs can all result in an undercut.

Furthermore, dirt and water have a tendency to get trapped in the groove, which can hasten corrosion in the area that is already weak.

Causes of Undercut

- High arc length.

- Incorrect electrode selection.

- Wrong angle.

Preventions of Undercut

- Smaller arc length.

- Small voltage.

- Small travel speed.

- Reducing the electrode diameter.

Undercut defect

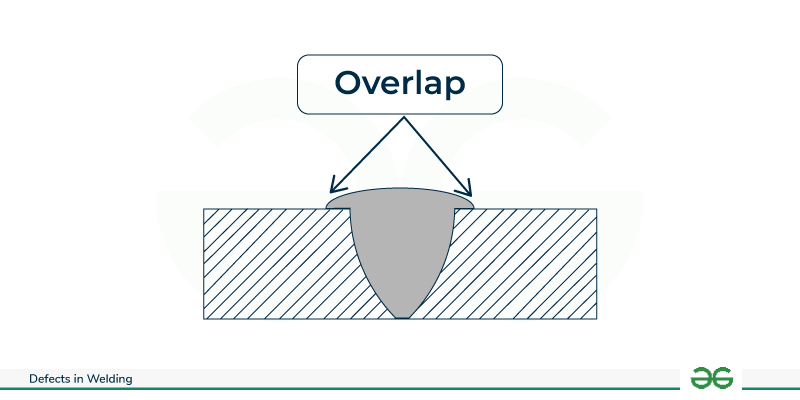

Overlap

The extra metal that extends around the bead is called overlap. The base metals are not adequately combined with the dispersed filler metal. It usually has a rounded form over the weld joint.

Causes of Overlap

- Wrong selection of metal.

- Incorrect welding procedure.

- Improper arrangement of base metal.

Preventions of Overlap

- The Smaller welding current.

- Use of proper welding techniques.

- Shorter welding electrode.

Overlap defect

Burn Through

When a burn-through or melt-through is created by the welding process inadvertently penetrating the entire thickness of the base metal, an exposed hole results. When welding thin metals, one of the most frequent weld faults is this one.

Causes of Burn Through

- High welding current.

- Extreme gap to the root.

- Not enough root face metal.

Burn Through

Preventions of Burn Through

- Maintaining a proper root gap.

- Use small welding current.

- By re-welding we can remove this defect.

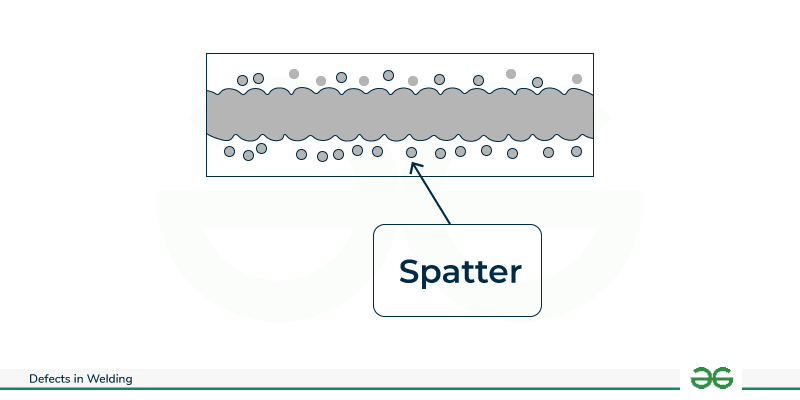

Spatter

When metal droplets are released onto a metal surface, a welding problem known as spattering takes place. When it cools, it hardens and sticks to the metal surface. Spatter often doesn’t affect the weld’s structural integrity, but it usually needs to be removed, which raises the overall cost.

Causes of Spatter

- High arc length

- High welding current.

- Improper shielding.

- Wrong polarity can create this defect.

Preventions of Spatter

- Correct welding polarity.

- Reduce the welding current.

- Selecting a better shielding gas.

- Better shielding technique.

Spatter defect

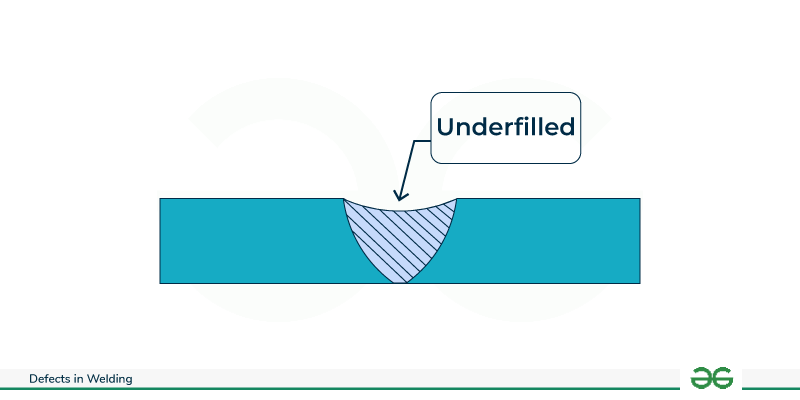

Underfilled

When there is insufficient weld metal deposited in the joint, underfill happens. Consequently, the joint is underfilled and a portion of the parent material is left unfused. Even in little regions, these unfused areas have the ability to cause stress.

Causes of Underfilled

- Welding current.

- Incorrect weld bead placement.

- To high travel speed.

Preventions of Underfilled

- Proper electrode size.

- Right current setting.

- Avoid fast moving.

Underfilled Defect

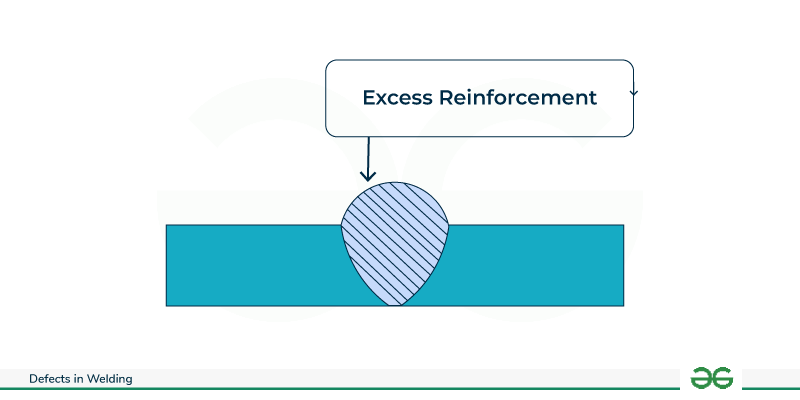

Excess Reinforcement

Overfilled, or excess reinforcement, welds that have an excessive amount of build-up. Since too much filler metal is put into the joint, it is the opposite of underfilled welds. High concentrations of stress accumulate in the weld toes as a result of this flaw.

Causes of Excess Reinforcement

- Travel speed.

- Incorrect procedures.

- Excess flux on the feed wire.

Preventions of Excess Reinforcement

- Maintain optimal pace.

- Avoid excess heat.

- Aligning the workpieces properly.

- Gap not two large.

Excess Reinforcement defect

Mechanical Damage

Indentations in a weld caused by preparation, handling, welding, equipment use, and other reasons are known as mechanical damage.

Causes of Mechanical Damage

- Incorrect handling.

- Unnecessary extra force.

- Not engaging the arc before the welding procedure.

Preventions of Mechanical Damage

- Safe and correct handling

- Engaging the arc metal before welding.

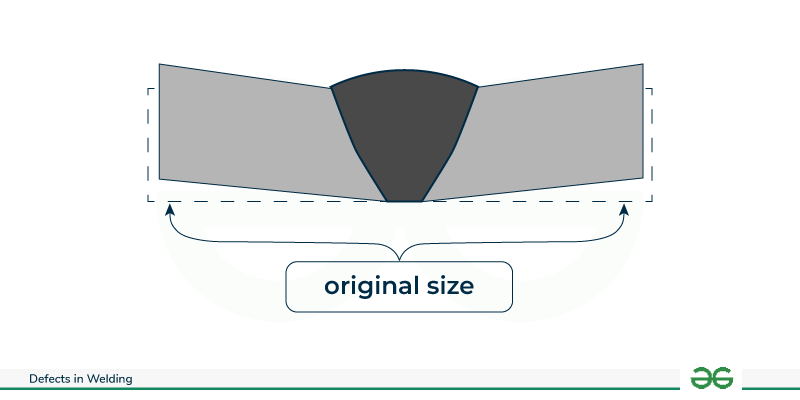

Distortion

An unintentional alteration in the form of the surrounding metal of the weld is called distortion or warping. The main cause of distortion in the vicinity of the weld joint is overheating. Four types of warpage or distortion are identified in thin metals: angular, longitudinal, fillet, and neutral axis.

Causes of Distortion

- Thin weld metal.

- High amount of weld passes.

- Incompatible base metal and weld metal.

Preventions of Distortion

- Correct metal.

- Optimising weld passes.

- Selection of better welding method.

Distortion defect

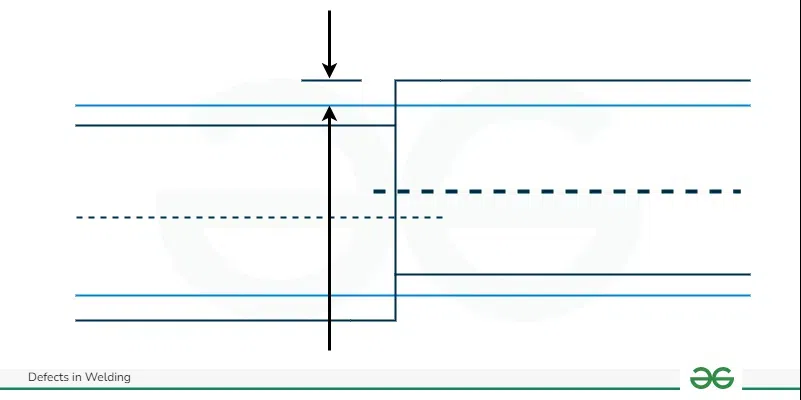

Misalignment

Misalignment can occur when metals are positioned incorrectly either before or during a welding procedure. Inadequate metal alignment can lead to fatigue problems, particularly when pipe welding is involved.

Causes of Misalignment

- Rapid welding process.

- Incorrect metal alignment.

- lack of skills.

Preventions of Misalignment

- Slow and reduce the rate of work.

- Correct welding technique.

- More stable welding procedure.

- Conducting checks regularly.

Misalignment defect

Internal Welding Defects

Internal welding faults are those produced by welding procedures that result in weld imperfections that are not visible to the human eye.

Different Types of Internal Welding Defects are

- Slag Inclusion

- Incomplete Fusion

- Incomplete Penetration

Slag Inclusion

The toughness and structure of the metal are compromised by a weld bead that has slag in it. Slag inclusion can happen between welding cycles or merely on the weld metal’s surface. This type of weld fault is frequently seen in flux-using procedures like brazing, stick, flux-cored, and submerged arc welding.

Causes of Slag Inclusion

- Poor cleaning of edge of the welding surface.

- Low welding current density.

- Incorrect welding angle.

- Travel speed of the welding torch.

Preventions of Slag Inclusion

- Using higher welding current density.

- Weld edge cleaning.

- Slag removal after each layer.

Slag inclusion

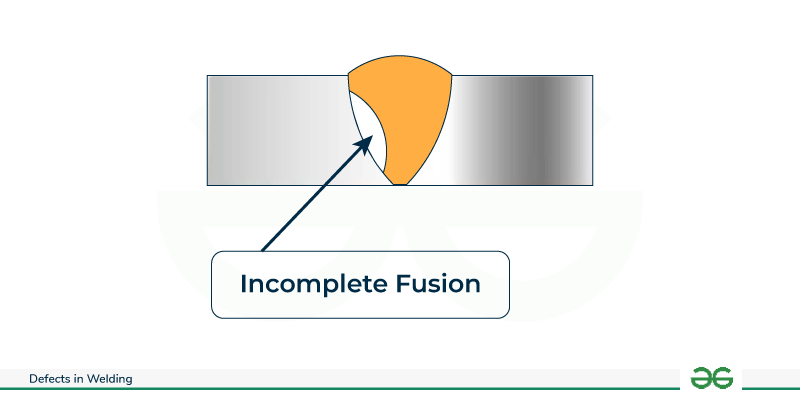

Incomplete Fusion

Poor welding causes the metals to pre-solidify and create gaps in the weld zone, which leads to incomplete fusion. Fusion fails when the welder is unable to adequately fuse the parent metal with the base metal.

Causes of Incomplete Fusion

- Low heating metal doesn’t melt properly

- Wrong joint angle

- Wrong torch angle

- Wrong bead position.

Preventions of Incomplete Fusion

- Low deposition rate.

- High welding current.

- Right angle of joint.

Incomplete fusion

Incomplete Penetration

Butt welding frequently results in incomplete penetration, which happens when the joint thickness isn’t thick enough to fill the space between the metals. This indicates that the joint’s one side is not fused to the root.

Causes of Incomplete Penetration

- Incorrect welding.

- Wrong electrode size.

- Incorrect welding technique.

Preventions of Incomplete Penetration

- High deposition rate.

- Proper electrode size.

- Using correct welding technique.

Incomplete Penetration

How to Detect Welding Defects

Testing techniques are a useful tool for determining if welding patterns satisfy requirements. It enables us to identify the root causes of welding problems and potential solutions. Even though it takes longer, it guarantees risk-free and secure welds.

We have Two methods to detects the welding defect,

- Destructive Testing

- Non-Destructive Testing

Destructive Weld Testing

Destructive testing gathers data by pushing completed projects to their limits using rigorous approaches. Destructive testing is sometimes necessary in conjunction to non-destructive testing to achieve a considerable reduction in weld faults in production. The limits of the weld metal can be found using destructive methods such tensile strength, guided bend, free bend, back bend, nick break, and acid etch.

Non-Destructive Weld Testing

Using testing methods that don’t change any of the characteristics of the product being examined is known as non-destructive testing. Its strength, integrity, toughness, conductivity, corrosion resistance, wear resistance, and other qualities could be among them.

Non-destructive assessment, non-destructive analysis, non-destructive examination, and non-destructive inspection are other names for non-destructive testing.

The product remains usable even after passing an NDT test. The test has not had any negative effects on the specimen

Conclusion

To joint two metals , gas metal arc welding is a technique used to fuse two or more materials together. The GMAW is still in use in industry today due to its smooth learning curve, ability to weld nearly any metal, and inexpensive equipment cost. Consequently, it can aid welders in honing their craft to create better joining processes. It will hence decrease faults. Additionally, by utilizing a steady voltage that gives more energy to achieve effective fusion, welding can prevent excess welding and poor fusion. It can also prevent the weld from burning through the material by lowering the voltages or energy. Furthermore, the welding process’s current ratio can be changed to manage the weld bead’s width. Wire speed can also be used to alter the weld bead’s height.

This parameter can be used based on the thickness of the component that needs to be joined as well as the required joining strength. Finally, the usage of welding will result in a number of welding process defects. When welding, this flaw can be minimized by employing the proper technique and expertise. The welder needs to get experience in the welding process by participating in training taught by an expert in the field. On the other hand, compared to manual welding, utilizing a robotic welding machine will also yield better results.

FAQs on Defects in Welding

Define term welding.

A series of techniques called welding is used to join two workpieces—steel in the case of SSAB. Usually, the two workpieces are locally melted to form a shared liquid pool by a single heat source, usually an electrical arc. The components are connected once the steel hardens. To achieve a good weld joint, it is frequently necessary to melt a specific steel rod or wire (consumable filler) into the weld pool.

List the defects in welding.

We have different types of defect which varies when weld process is done. All defects mention below

- Undercut

- Spatter

- Slag inclusions

- Cracks

- Porosity

- Overlap

Why does the plate deform after welding ?

Different peak temperatures will cause different plate shrinkage in the area around the welded connection, and different-sized residual strains may also manifest. While thick plates will have more strains, thin plates will respond with deformation and stress relaxation.

What is the reason behind when welding joints fails?

There are numerous reasons why a welded junction could malfunction. The most prevalent ones are residual stresses, weak microstructure, and physical discontinuities. These factors, which include design selection, joint type, joint geometry, welding procedure, heat input, preheating, and welding consumables, are caused by a number of parameters.

Share your thoughts in the comments

Please Login to comment...