A vacuum circuit breaker is a type of breaker that utilizes a vacuum as the medium to extinguish electrical arcs. Within this circuit breaker, there is a vacuum interrupter that houses the stationary and mobile contacts in a permanently sealed enclosure. When the contacts are separated in a high vacuum environment, the electrical arc is effectively extinguished. As an illustration, when the contacts of a circuit breaker are opened within a vacuum environment, the interruption takes place precisely at the moment of the initial current reaching zero. This results in the dielectric strength between the contacts rapidly increasing at a rate thousands of times greater than what is achieved with alternative types of circuit breakers.

What is Vacuum Circuit Breaker?

A vacuum circuit breaker is a type of breaker that employs a vacuum as the medium for extinguishing arcs. The permanently sealed vacuum interrupter of this circuit breaker houses both the fixed and movable contacts. The separation of contacts within a high vacuum ensures the extinction of the arc. This device is used to prevent the unexpected current which is caused because of the short circuit in any system. Also it interrupts the voltage in some applications .Basically arc quenching takes place in this in the vacuum medium. Insulating medium is high for the arc extinction as compared to the other circuit breakers.

Vacuum-Circuit-Breaker

Types of Vacuum Circuit Breaker

Some types of Vacuum Circuit Breaker are as follows:

- Hybrid Vacuum Circuit Breaker

- Axial Magnetic field Vacuum Circuit Breaker

- SF6 Vacuum Circuit Breaker

- The Oil Vacuum Circuit Breaker

Hybrid Vacuum Circuit Breaker

The hybrid circuit breaker represents an enhanced low-voltage direct current (LVDC) breaker incorporating current injection, leveraging a pre charged capacitor. This innovation significantly augments the dielectric recovery performance of the vacuum interrupter subsequent to the artificial current zero, achieved through the incorporation of a freewheel diode.

Hybrid circuit breakers represent a category of protective devices designed to effectively manage fault current and ensure rapid interruption in both AC and DC power systems. These breakers play a pivotal role in supporting multi-terminal DC transmission and distribution systems, serving as a crucial enabling technology. As the power capacity of DC systems continues to rise, the adoption of mechanical switches within the normal conduction path becomes a preferred choice to minimize on-state losses in hybrid circuit breaker configurations.

Hybrid Vacuum Circuit Breaker

Axial Magnetic Field Vacuum Circuit Breaker

The Axial Magnetic Field Vacuum Breaker utilizes a magnetic field along the axis to swiftly extinguish arcs. It finds application in medium-voltage scenarios, effective up to 72.5 kV’.

Axial Magnetic Field Vacuum Circuit Breaker

A specific magnetic field determines the minimum arc voltage. In this state, the interrupting current sees a significant boost, and it’s closely tied to the electrode diameter. Approximately a decade ago, a useful axial magnetic field electrode was created for vacuum circuit breakers. Since then, ongoing enhancements to its structure have made it suitable for practical use in interrupters for vacuum circuit breakers.

This application has proven successful not just in medium-voltage circuit breakers but also in high-voltage (up to 84 kV), DC high-voltage, and high-current circuit breakers. This paper outlines a decade of experience and improvements in this field.

SF6 Vacuum Circuit Breaker

The SF6 Vacuum Circuit Breaker utilizes the insulating and arc-quenching characteristics of SF6 gas within its interrupter chamber, resulting in a more compact size compared to air blast breakers.SF6 gas exhibits a robust electronegativity, facilitating the easy removal of free electrons during discharge through the formation of negative ions. Notably, it possesses a distinctive quality of rapid recombination post the cessation of the energizing spark source, rendering it a remarkable 100 times more effective compared to other arc-quenching mediums.

With a dielectric strength 2.5 times greater than that of air and 30% less than traditional dielectric oil, SF6 gas further distinguishes itself. Notably, its dielectric strength experiences an augmentation under high pressure conditions.

SF6 Vacuum Circuit Breaker

It’s imperative to underscore that moisture poses a significant threat to SF6 circuit breakers. The amalgamation of humidity and SF6 gas leads to the formation of hydrogen fluoride during arc interruption, posing a potential risk to the integrity of circuit breaker components.

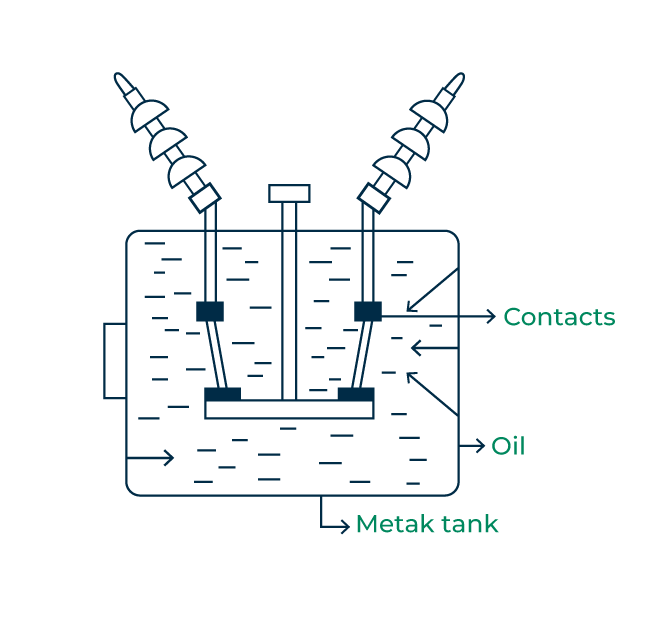

The Oil Vacuum Circuit Breaker

The Oil Vacuum Circuit Breaker relies on an insulating oil medium within its tank, in conjunction with vacuum interrupters. However, this antiquated design is less prevalent today due to environmental apprehensions associated with oil usage.

The Oil Vacuum Circuit Breaker

An Oil Circuit Breaker, also known as OCB, is a specific type of circuit breaker that relies on insulating oil to safely stop electrical arcs and interrupt circuits. This insulating oil, often transformer oil, has superior dielectric strength compared to air. When the arc generates heat, it causes the oil to vaporize, creating a bubble of hydrogen gas around the arc. The pressure from the oil compresses this gas bubble, making it stronger and effectively putting out the arc when the electrical current reaches zero.

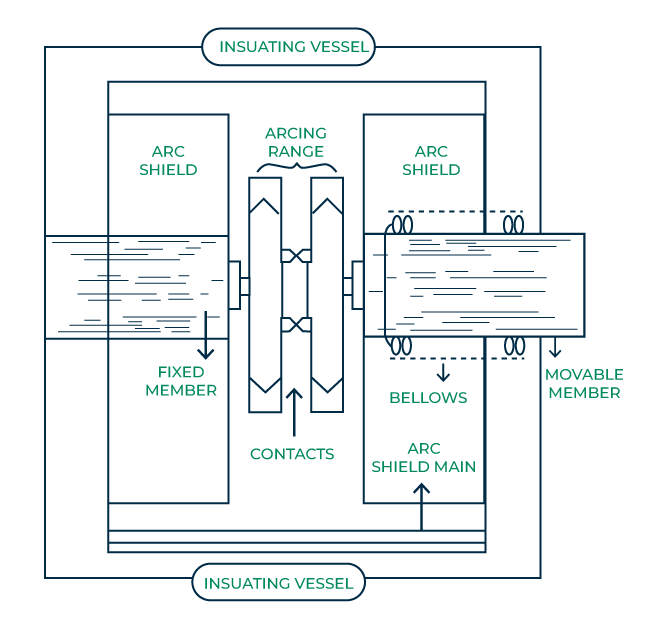

Construction of Vacuum Circuit Breaker

The construction of a vacuum circuit breaker is easy when compared to other types of circuit breakers. It primarily consists of three key components: fixed contacts, moving contacts, and an arc shield located within the arc interruption chamber. The outer casing of the vacuum circuit breaker is crafted from glass, which enables external inspection of the breaker’s condition after operation. If the glass changes from its original mirrored appearance to a milky one, it signals a loss of vacuum within the breaker. The fixed and moving contacts are housed within the arc shield, and during the sealing process, the vacuum interrupter is maintained at approximately 10^-6 torr. The extent of movement for the circuit breaker’s moving contacts typically ranges from 5 to 10 mm, depending on the operating voltage. The most important is the design of the metallic below because the durability of this device depends on the repeated operations performed.

Construction of Vacuum Circuit Breaker

Stainless steel metallic bellows are employed to actuate the movement of the moving contacts, and the design of these metallic bellows is of utmost importance, as the durability of the vacuum circuit breaker relies on the component’s ability to perform repeated operations reliably.

Working Principle of Vacuum Circuit Breaker

When the contacts of the circuit breaker are separated within the vacuum environment, typically ranging from 10^-7 to 10^-5 torr, an arc is generated between the contacts through the ionization of metal vapors emitted by the contacts. So as the fault occurs in the system , contact of the breaker is moved apart and arc is developed between this.

However, this arc is promptly extinguished because the metallic vapors, along with electrons and ions produced during the arc, swiftly condense on the surfaces of the circuit breaker contacts. This rapid condensation leads to a swift restoration of the dielectric strength. The key characteristic of using vacuum as an arc quenching medium is that as soon as the arc forms within the vacuum, it is rapidly extinguished due to the high-speed recovery of dielectric strength within the vacuum. So arc does not restrike again as the metal vapour is removed from that zone of operation.

Working of Vacuum Circuit Breaker

In the event of a fault in the system, the circuit breaker’s contacts are separated, leading to the formation of an electrical arc between them. As the current-carrying contacts are pulled apart, the temperature at their connecting points becomes significantly high, resulting in ionization. This ionization process fills the contact space with positive ion vapors emitted from the contact material.

Working of Vacuum Circuit Breaker

The density of these vapors depends on the current magnitude during the arcing phase. As the current wave diminishes, the rate of vapor release decreases, and once the current reaches zero, the medium regains its dielectric strength as the vapor density around the contacts diminishes. Consequently, the arc is prevented from restriking because the metal vapor is swiftly removed from the contact area.

Current chopping in a vacuum circuit breaker is influenced by both the vapor pressure and the electron emission characteristics of the contact material. The level of chopping is also affected by thermal conductivity, with lower thermal conductivity resulting in reduced chopping levels.

It is theoretically possible to lower the current level at which chopping occurs by selecting a contact material that releases enough metal vapor to allow the current to decrease significantly or reach zero. However, this is rarely employed in practice as it can adversely impact the dielectric strength of the system.

Tests of Vacuum Circuit Breaker

Some of the test perform of the Vacuum Circuit Breaker are:

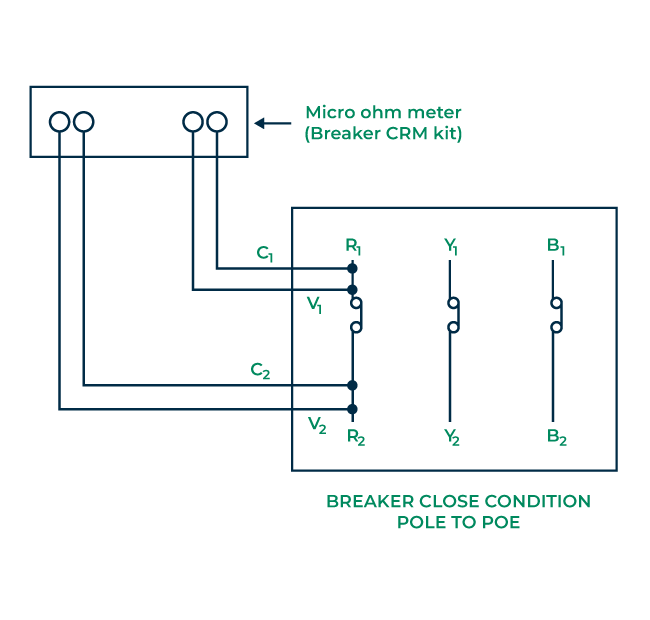

- Contact Resistance Test

- High Potential Testing

Contact Resistance Test

A contact resistance test using a micro-ohmmeter, where the resistance is measured and documented. The obtained result is then compared to either the design specifications or the average values of other Vacuum Interrupters within the same operation. Contact resistance testing, commonly referred to as Ductor testing, involves assessing the resistance in electrical connections, including terminations, joints, connectors, busbar sections, and cable connections. These assessments apply to connections between any two conductors, such as cable links or busbar sections. The instrument employed for conducting the Ductor test is called an Ohmmeter, also known as a Ductor tester due to its dedicated function.

Contact Resistance Test

Ductor testers come in various variants, including Micro, Mega, and Milli-Ohmmeters, as well as static resistance testers or DLRO, which stands for Digital Low Resistance Ohm Meter. These instruments are crucial for measuring resistance in diverse applications within the realm of electrical testing.

High Potential Testing

The open contacts of the vacuum interrupter (VI) undergo a high potential voltage test, where the voltage is incrementally raised to the specified test value, and any resulting leakage current is measured. Factory testing can utilize either AC or DC high-potential test sets, and various portable test sets from manufacturers are accessible for conducting high-potential tests on open vacuum interrupters.

The high potential test is designed to ascertain whether a bus bar can endure its specified withstand voltage once installed on-site or if it is prone to breakdown. Additionally, it aims to evaluate the integrity of the vacuum bottle, measure leakage current, and assess insulation between the circuit breaker (CB) and the ground. The essential testing equipment for conducting a high potential test includes an AC high-voltage injection machine (100KV, 60HZ), a Megger 5KV DC supply, and tools for mechanical and visual inspection.

High Potential Testing

During the test, it is crucial to verify the adequate clearance (distance) between the circuit test ends and other grounded objects, as well as other phases not under test. Additionally, attention must be given to maintaining sufficient clearance with other electrical equipment to prevent potential flashovers. These precautionary measures contribute to the reliability and safety of the high potential testing process.

What is Current Chopping in Circuit Breaker?

Current chopping in a circuit breaker refers to the phenomenon where the current is intentionally interrupted before reaching natural current zero. This occurrence is particularly notable in Vacuum Circuit Breakers and Air Blast Circuit Breakers, while it is absent in Oil Circuit Breakers. Current chopping is most pronounced during the switching of a Shunt Reactor or an unloaded Transformer.

In the context of a reactor, the energy stored in its inductance is transferred to a capacitor.

|

Vacuum Circuit Breaker

|

Vacuum Contact Unit

|

|

A Vacuum Circuit Breaker is a specialized circuit breaker designed to safeguard high-voltage systems from potential damage.

|

A vacuum contactor is a device capable of enduring numerous operations with a strong mechanical lifespan.

|

|

They are commonly employed for voltage levels ranging between 3 kV and 36 kV.

|

The necessary ratings those of vacuum contactors, reaching values of 200 A or 630 A at voltages up to 15 kV.

|

|

The loads contain transformers, capacitors, sizable motors, generators, or distribution feeders.

|

The continuity of the process aligns with the time required for fuse replacement.

|

|

Switching occurrences are infrequent.

|

Switching occurrences are frequent.

|

Applications of Vacuum Circuit Breaker

- The vacuum circuit breaker, known as VCB, finds application in various industrial settings as a high-speed switching device.

- These circuit breakers are well-suited for systems operating within the voltage range of 11V to 33 kV.

- They are commonly paired with static overcurrent relays to achieve a total clearance time of less than 40 milliseconds in the case of phase-to-phase faults.

- VCBs are employed in high-voltage circuits, generators, and electrical substations.

- They are particularly useful for interrupting both double earth faults and phase currents.

- These breakers are the choice when rapid and high-frequency switching is required, and they also serve in railway applications for tasks like electric supply switching and managing traction current.

- The vacuum circuit breakers play a significant role in switching motor drives in various applications.

Advantages and Disadvantages of Vacuum Circuit Breaker

The advantages and disadvantages of the circuit breaker are given below:

Advantages

- There is no risk of fire hazards.

- Vacuum exhibits strong dielectric properties.

- No gas is produced after the operation.

- Offers an eco-friendly alternative compared to SF6 circuit breakers.

- Operates quietly with minimal vibrations.

Disadvantages

- High-tech production of vacuum interrupters demands the inclusion of supplementary surge suppressors to handle the interruption of low magnetizing currents within a specific range.

- Further, any loss of vacuum during transit damage or failure renders the entire interrupter inoperable, with no possibility of on-site repair.

- Initial cost is more.

- There is a limited current carrying capacity.

- It requires maintenance to protect from dust, moisture and some environmental conditions.

- High Density

- High Electrical conductivity of the material so that normal load current can pass easily

- High arc withstand ability of the material

- Current chopping level must be low.

Conclusion

The using of vacuum circuit breakers has been increasing due to their dependable performance in medium voltage networks. Additionally, they abolish the requirement for costly switchgear, particularly crucial in low or high-voltage networks. Vacuum circuit breakers are engineered to automatically open and close in response to signals from sensors. Vacuum circuit breakers are primarily employed for medium voltage applications, typically in the range of 11 KV to 33 KV.

FAQs on Vacuum Circuit Breaker

What is the definition of Vacuum Circuit Breaker?

A vacuum circuit breaker is a type of breaker that utilizes a vacuum as the medium to extinguish electrical arcs. Within this circuit breaker, there is a vacuum interrupter that houses the stationary and mobile contacts in a permanently sealed enclosure.

What are the advantages of Vacuum Circuit Breakers Over Other Types?

There is no risk of fire hazards. Vacuum exhibits strong dielectric properties. No gas is produced after the operation. Offers an eco-friendly alternative compared to SF 6 circuit breakers.

What are the Voltage Ranges for Vacuum Circuit Breakers?

When the contacts are separated in a high vacuum environment, the electrical arc is effectively extinguished. Vacuum circuit breakers are primarily employed for medium voltage applications, typically in the range of 11 KV to 33 KV.

What is the applications of Vacuum Circuit Breakers in Power Distribution?

They are particularly useful for interrupting both double earth faults and phase currents. These breakers are the choice when rapid and high-frequency switching is required, and they also serve in railway applications for tasks like electric supply switching and managing traction current. The vacuum circuit breakers play a significant role in switching motor drives in various applications.

Share your thoughts in the comments

Please Login to comment...