In this article, we will be going through Circuit Breakers, We will Look at different Types of Circuit Breakers which are categorized as Low Voltage Circuit breakers, Medium to High Voltage Circuit breakers, Circuit Breakers based on Operations, and Gas Circuit Breakers. In Low Voltage Circuit Breaker we will be Going Through MCB and RCCB. In Medium to High, we will be going Through ACB, Oil Circuit Breaker, Vaccum Circuit Breaker, Sulphur Hexafluoride Circuit Breaker, and HDVC Circuit Breaker. Based on the operation of circuit breakers we will be going through Dead Tank Circuit Breakers, Spring-operated Circuit Breakers, and Pneumatic Operated Circuit Breaker. At last, in the Gas Circuit Breaker, we will go through the SF6 Circuit Breaker.

What is a Circuit Breaker?

An electrical switch is one kind of electric device, used to break any circuit physically through somewhat under ordinary conditions. The principal capability of an electrical switch or CB is to break a circuit in some fault conditions like a short circuit, over-current, and so on. For the most part, an electrical switch switches or safeguards the framework. A few gadgets related to circuit breakers like relays; switches, fuses, and so on are additionally utilized for a similar purpose. The uses of circuit breakers incorporate power frameworks and ventures for safeguarding and controlling different parts in the circuit like transformers, change gears, motors, alternators, generators, and so on. There are various types of circuit breakers utilized in industries.

What is Arc Quenching in Circuit Breaker?

To begin with, we need to realize what an is arc prior to going to talk about an arc extinguishing. In-Circuit Breakers, while opening the current carrying contacts, the medium middle of opening contacts transforms into very ionized all through which the interrupting current on flow will get less resistive path and keeps on providing all through this path even the flow current carrying contacts are isolated physically. At the point when current streams start with one contact and then onto the next, the path will turn out so heated that it blasts. This is known as an arc.

The arc extinguishing is additionally called arc Interruption or arc Extinction, so it is the stoppage of the arc and metal exchange. To break high voltages, then care should be taken to reduce much progression of current at the hour of opening contact to reduce the metal exchange. So diminishing the current flow will increase the contact’s life.

Types of Circuit Breaker

There are lots of type types of circuit breakers. Some of the important types are discussed below:

- Low-Voltage Circuit Breaker

- Medium to High Voltage Circuit Breakers

- Based on Operations

- Gas Circuit Breakers

Low-Voltage Circuit Breaker

It is divided into two types:

- Miniature Circuit Breaker (MCB)

- Residual Current Circuit Breaker (RCCB)

Miniature Circuit Breaker (MCB)

A Miniature Circuit Breaker (MCB) is a kind of electrical circuit protection gadget utilized in commercial, industrial, and modern electrical systems. MCBs are intended to consequently hinder electrical circuits in case of over flows, short circuits, or other electrical flaws. They assume a critical part in ensuring the safety of electrical establishments and preventing damage to equipment. Here are key highlights and qualities of MCBs:

- Smaller Size: MCBs are reduced and space-saving gadgets, which makes them reasonable for use in appropriation sheets, electrical boards, and shopper units where space is restricted.

- Modular Design: MCBs have a measured plan, taking into consideration simple establishment and substitution. They can be immediately snapped onto standard Racket rail mounting frameworks normally utilized in electrical boards.

- Current Rating: MCBs are accessible in different flow appraisals to match the particular prerequisites of various electrical circuits. Normal current evaluations range from a couple of amperes (e.g., 6A, 10A, 16A) to higher qualities (e.g., 32A, 63A).

- Voltage Rating: MCBs are commonly evaluated for use in low-voltage electrical frameworks, with standard voltage appraisals of 230/400 volts AC for single-stage frameworks and 400/415 volts AC for three-stage systems.

- Overcurrent Protection: MCBs are principally intended to safeguard against over flows. At the point when the ongoing in a circuit surpasses the MCB’s evaluated current for a predefined period (normally customizable), the MCB trips, intruding on the circuit to forestall overheating and likely damage.

- Short- Circuit Protection: MCBs likewise give cut off. In case of a short out (an unexpected and very high current), the MCB answers quickly to intrude on the circuit and forestall further damage

Working of MCB

The working of a Miniature Circuit Breaker (MCB) includes a succession of moves toward give dependable security against over flows, short circuits, and other electrical shortcomings in electrical circuits. MCBs are intended to consequently trip (interfere with) the circuit when certain shortcoming conditions are recognized.

Advantages of MCB

- Easy to operate

- Portable Device

- Quick Response

- Resettable

- Compact and space required is less

Disadvantages of MCB

- Limited Breaking Capacity

- Sensitivity to Environmental Factors

- Not Suitable for DC Circuits

- Limited Arc Flash Protection

Applications of MCB

- Residential Electrical Panels

- Commercial Building

- Industrial Facilities

- Manufacturing Plants

- Agricultural Applications

- Renewable Energy Installations

Residual Current Circuit Breaker (RCCB)

A Residual Current Circuit Breaker (RCCB), otherwise called a Residual Current Device (RCD), is an electrical safety device intended to safeguard against electric shock and forestall electrical flames brought about by ground deficiencies or spillage flows. RCCBs are normally utilized in private, business, and modern electrical frameworks to give an extra layer of security past customary overcurrent circuit breakers or wires. This is a clarification of the way RCCBs work and their key highlights:

Operation and Key Features

- Detection of Ground Faults: RCCBs consistently screen the electrical flow streaming in a circuit. They look at the approaching current on the live (stage) guide with the active current on the impartial guide. Under ordinary circumstances, the flow entering and leaving the RCCB ought to be equivalent, it is adjusted to show that the electrical circuit.

- Imbalance Detection: Assuming there is a imbalance between the approaching and active flows, it proposes that a piece of the current is spilling from the circuit, conceivably because of a ground shortcoming. RCCBs are profoundly touchy and can identify even little spillage flows as low as a couple of milliamperes.

- Tripping Mechanism: When the RCCB recognizes an unevenness past a preset limit (generally 30 mA or 300 mA, contingent upon the application and wellbeing guidelines), it quickly excursions or disengages the circuit inside a negligible portion of a second. This activity keeps the spillage flow from arriving at hazardous levels and causing electric shock or electrical flames.

- Manual Reset: After a RCCB trips because of a ground issue, it very well may be physically reset by flipping the change to the “OFF” position and afterward back to the “ON” position. This element considers simple reclamation of force after a shortcoming is settled.

.webp)

Residual Current Circuit Breaker (RCCB)

Applications of RCCB

- Residential Electrical Panels: RCCBs are ordinarily introduced in private electrical dissemination boards to safeguard circuits serving outlets, lighting, and other home devices.

- Commercial Buildings: They are utilized in business conditions to safeguard circuits in workplaces, retail spaces, eateries, and other business foundations.

- Industrial Facilities: RCCBs are utilized in modern settings to safeguard circuits powering machinery, equipment, and industrial processes.

- Construction Sites: Convenient RCCBs are involved on building locales to give ground issue assurance to brief electrical distribution and power instruments.

- Outdoor Electrical Installations: RCCBs are much of the time utilized in open air establishments to safeguard circuits in garden lighting, wellsprings, and other outside electrical equipment.

Medium to High Voltage Circuit Breakers

- Air Circuit Breaker (ACB)

- Oil Circuit Breaker

- Vacuum Circuit Breaker

- Sulphur Hexafluoride (SF6) Circuit Breaker

- HDVC(High Voltage Direct Current) Circuit Breaker

Air Circuit Breaker (ACB)

Air Circuit Breaker (ACB) is an electrical gadget used to give Overcurrent and Short-circuit protection for electric circuits over of 800 Amps to 10K Amps. These are typically utilized in low voltage applications beneath 450V. We can find these frameworks in Distribution Boards (underneath 450V). Here in this article, we will talk about the working of Air Electrical switch. An air electrical switch is a circuit activity breaker that works in the air as an arc extinguishing medium, at a given environmental tension. There are a few kinds of air circuit breakers and changing gears accessible in the market today that are durable, high-performing, simple to introduce and keep up with. The air circuit breakers have totally replaced by oil circuit breakers.

Construction

The development of an air circuit breaker should be possible by utilizing different inside and outer parts like the following.

The outer pieces of ACB basically incorporate the ON and OFF button, a marker for the place of the primary contact, a pointer for the instrument of energy storage, rocker repository, LED indicators, displays, RST button, controller, appraised nameplate, handle for energy capacity, shake, fault trip rest button, and so on.

Air Circuit Breaker

The inner pieces of ACB mainly incorporate supporting construction with steel sheet, the current transformer used to protect the outing unit, post bunch protecting box, level terminals, arcing chamber, trip unit for insurance, terminal box, shutting springs, CB opening and shutting control, plates to move arcing and fundamental contacts, plates for fixed primary and arcing contacts.

Working Principle

- The air circuit breaker working principle is different as contrasted and different kind of CBs. We realize that the fundamental capability of CB is to stop the rebuilding of arcing any place the hole between contacts will oppose the recuperation voltage of the system.

- The air circuit breaker likewise works the equivalent yet another way. While interfering with a bend, it makes a curve voltage instead of the voltage supply. This voltage can be characterized as the least voltage which is important to keep up with the curve. The voltage supply can be expanded in three unique ways by an electrical switch.

- The arc voltage can be upgraded through cooling circular segment plasma.

- When the temperature of curve plasma and molecule movement is diminished, then, at that point, extra voltage angle will be important to keep the circular segment. The curve voltage can be expanded by parting the circular segment into a few series

- When the circular segment way is expanded then Curve voltage can likewise be expanded. As before long circular segment way length is upgraded then the way of obstruction will likewise expand the curve voltage which is utilized across the bend way subsequently bend voltage can be expanded.

- The scope of working voltage is upto 1KV. It incorporates two arrangements of contact where the significant pair involves the current as well as the contact made with copper. One more sets of contact can be made with carbon. When the electrical switch is opened, the main significant contact opens.

- While opening the significant contact, the bend contact stays associated. At the point when curve contacts are isolated then arcing begins. The electrical switch is obsolete for normal voltage

Working

Air circuit breakers work with their contacts in free air. Their technique for circular segment extinguishing control is altogether not quite the same as that of oil circuit-breakers. They are constantly utilized for the low-voltage interference and presently will in general supplant high-voltage oil breakers. The below shown figure outlines the rule of air breaker circuit activity.

Air Circuit breakers by and large have two sets of contacts. The principal sets of contacts (1) conveys the current at typical burden and these contacts are made of copper metal. The subsequent pair is the arcing contact (2) and is made of carbon. At the point when the electrical switch is being opened, the fundamental contacts open first. At the point when the primary contacts opened the arcing contacts are still in contact with one another.

As the current helps an equal low resistive way through the arcing contact. During the opening of the main contacts, there won’t be any arcing in the primary contact. The arcing is possibly started when at last the arcing contacts are isolated. Every one of the curve contacts is fitted with a circular segment sprinter which makes a difference.

The bend release moves up because of both warm and electromagnetic impacts as displayed in the figure. As the curve is driven vertical it enters the circular segment chute, comprising of splatters. The curve in the chute will become colder, stretch, and split subsequently bend voltage turns out to be a lot bigger than the framework voltage at the hour of activity of an air electrical switch, and in this way the circular segment is doused at last during the flow zero.

The compressed air brake circuit box is made of protecting and flame resistant material and it is partitioned into various areas by the boundaries of a similar material. At the lower part of every hindrance is a little metal directing component between one side of the obstruction and the other. At the point when the curve, driven upwards by the electromagnetic powers, enters the lower part of the chute, it is parted into many segments by the obstructions, however every metal piece guarantees electrical congruity between the bends in each part, the few bends are thus in the series.

The electromagnetic powers inside every single part of the chute make the circular segment in that segment start the type of a helix, as displayed above, figure (b). Every one of these helices are in series with the goal that the absolute length of the curve has been extraordinarily expanded, and its obstruction is bounteously expanded. This will influence the ongoing decrease in the circuit.

Figure (a) shows the improvement of the curve from the time it leaves the principal contacts until it is inside the circular segment chute. At the point when the ongoing next stops at an ongoing zero, the ionized air in the way of where the bend had been being in lined up with the open contacts and goes about as a shunt obstruction across both the contacts and the self-capacitance C, displayed in the beneath figure with red as a high opposition R.

At the point when the wavering beginnings among C and L as depicted for the romanticized electrical switch displayed in Figure beneath, this opposition damps the swaying vigorously. Surely, it is normally weighty to such an extent that the damping is basic, the swaying can’t then happen by any means, and the restricking voltage, rather than showing up as a high-recurrence wavering, ascents loser to its inevitable worth of pinnacle generator voltage. This is displayed beneath the lower waveform.

Idealized Circuit Breaker with Waveforms

Advantages

The benefits of an air electrical switch incorporate the accompanying.

- High velocity re-terminations office

- Utilized for regular activity

- maintenance is less compared with other circuit breaker

- High velocity activity

- Fire chance can be wiped not like in oil circuit breakers

- Steady and short arcing time, so burning of contacts is less

Disadvantages

- A drawback of the arc chute principle is its shortcoming at low currents where the electromagnetic fields are weak.

- The actual chute isn’t really less effective in its extending and de-ionizing activity than at high flows, however the circular segment development into the chute will in general turn out to be more slow, and fast interference isn’t really obtained.

Applications

Air Circuit Breakers are utilized for controlling the power station helpers and modern plants. They offer security to modern plants, electrical machines like transformers, capacitors, and generators.

- They are essentially utilized for the insurance of plants, where there are potential outcomes of fire or blast risks.

- The compressed air brake standard of the air breaker circuit bend is utilized in DC circuits and AC circuits up to 12KV.

- The air circuit breakers have high obstruction power that aides in expanding the opposition of the curve by parting, cooling, and extending.

- An air electrical switch is likewise utilized in the Power sharing framework and NGD around 15kv

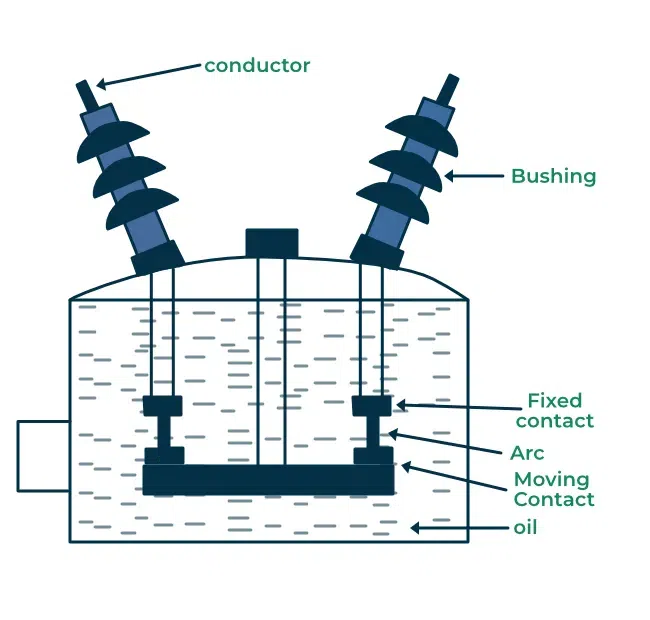

Oil Circuit Breaker

The most established type of circuit breaker is an oil circuit breaker. It incorporates separate contacts and the primary function of these contacts is to separate a protecting oil. It has great protecting properties contrast and air. At the point when the issue happens then the contacts of the breaker will open underneath the oil. When the curve is struck among the two contacts of the breaker then the intensity of the circular segment will disintegrate the encompassing oil and isolates into a critical volume of vaporous hydrogen at high tension. The fundamental elements of this electrical switch are minimal expense, unwavering quality, and simplicity.

Construction

The construction of this type of e Circuit Breaker is very simple. It incorporates current-carrying contacts that are encircled in areas of strength for a metal tank. Here the tank is stacked with transformer oil. The transformer oil fills in as a cover and arc extinguishing medium among the current component and earth.

Oil Circuit Breaker

At the peak of the transformer oil, the air can be filled inside the tank that goes about as a cushion to deal with the moved oil on the making of gas in the locale of the circular segment. It assimilates the mechanical shock of the rising development of oil. The oil tank in this breaker will be dashed to complete the vibration that is caused while intruding on the high progression of current. This incorporates a gas outlet which is fixed in the oil tank cover for the disposal of the gases.

.webp)

Miniature Circuit Breaker (MCB)

Working

In ordinary activity of this electrical switch, the contact in the breaker will be shut as well as conveys the flow. When the shortcoming occurs inside the framework, then the contacts will move separated and a circular segment will be struck among the contacts

Due to this arc, a gigantic measure of intensity will be delivered and high temperature can be accomplished to disintegrate the close by oil to gas. So this gas will be encircled by the curve and its shaky increment around it will move the oil savagely.

The arc will be switched off once the space between the contacts like fixed and moving shows up at a specific basic worth. It essentially relies upon the recuperation voltage and bend current. The activity of this electrical switch is very dependable and modest. The primary element of this electrical switch is, there is no specific gadgets are utilized while controlling the circular segment which is brought about by moving contact.

Advantages

- It utilizes less measure of oil

- Dielectric strength of oil is high

- Oil in the breaker will retain the energy of bend while disintegrating.

- Less space

- Hazard of fire can be diminished

- It reduces Maintenance

Disadvantages

- It utilizes less amount of oil with the goal that carbonization sum will be expanded

- Eliminating of the gases inside the contact space is troublesome

- The dielectric strength will declines the oil rapidly due to the high amount of carbonization.

- It is high to Circular segment time

- Try not to permit interference with fast

- Controlling of circular segment interference should be possible in view of the length of curve.

- It can frame any unstable combination through the air

Vacuum Circuit Breaker

A vacuum Circuit Breaker is a type of Circuit Breaker where the arc extinguishing happens in a vacuum medium. The activity of turning on and shutting of current carrying contacts and interrelated arc interference happens in a vacuum chamber in the breaker which is known as a vacuum interrupter.

A vacuum that is utilized as the circular segment extinguishing medium in an circuit breaker is known as a vacuum circuit breaker since vacuum invigorates high protecting because of superior arc extinguishing properties. This is reasonable for most standard voltage applications on the grounds that, for higher voltage, vacuum innovation was grown anyway not monetarily practical.

The activity of current-conveying contacts and related circular segment interference occur inside a vacuum office of the breaker, which is known as a vacuum interrupter. This interrupter incorporates a steel curve chamber inside the focal point of evenly positioned clay covers. The upkeep of vacuum strain inside a vacuum interrupter should be possible at 10-6 bar. The vacuum circuit breaker execution essentially relies upon the material utilized for flow conveying contacts like Cu/Cr

Working Principle

The vacuum circuit breaker working principle is, when the electrical switch contacts are opened inside the vacuum, then, at that point, a circular segment can be produced among the contacts through the metal fumes ionization in the contacts. Be that as it may, the circular segment can be extinguished effectively as the electrons, particles and metallic fumes are created all through the curve rapidly gather over the exterior of the CB contacts, so the dielectric strength can be immediately recuperated.

The main component of a vacuum is that once the circular segment is produced inside the vacuum, then, at that point, it tends to be quenched rapidly due to the fast improvement rate in the dielectric strength of the vacuum.

Construction

The vacuum Circuit Breaker contains a steel arc chamber in the middle evenly organized ceramic encasings. The strain inside the vacuum interrupter is kept up with beneath 10-4 torr.

The material utilized for current-conveying contacts assumes a significant part in the exhibition of the vacuum electrical switch. Amalgams like, Copper-bismuth or copper-chrome is the best material to make VCB contacts.

Vacuum Circuit Breaker

From the figure displayed over, the Vacuum Circuit Breaker comprises of fixed contact, a moving contact, and a vacuum interrupter. The moving contact is associated with the control system by hardened steel roar. The curve safeguards are upheld o the protecting lodging with the end goal that they cover these safeguards and is kept from gathering on the protecting nook. The chance of a hole is disposed of because of the extremely durable fixing of the vacuum chamber for that a glass vessel or ceramic vessel is utilized as the external protecting body.

Working

The sectional perspective on a vacuum Circuit Breaker is displayed in the figure beneath when the contacts are isolated because of a few unusual circumstances, a curve is struck between the contacts, the bend is delivered because of ionization of metal particles and relies especially upon the material of contacts.

The circular segment break in vacuum interrupters is not the same as different sorts of circuit breakers. The partition of contacts causes the arrival of fume which is occupied in the contact space. It comprises of positive particles freed from the contact material. The fume thickness relies upon the ongoing in the bend. At the point when the flow diminishes, the pace of fume discharge diminishes, and after flow zero, the medium recaptures its dielectric strength on the off chance that the fume thickness is decreased.

At the point when the current to be intruded on is tiny in a vacuum, the curve has a few equal ways. The absolute current is partitioned into many equal bends that repulse one another and spread over the contact surface. This is known as a diffused arc segment which can be intruded on without any problem.

At high upsides of current, the circular segment gets packed in a little district. It causes fast vaporization of the contact surface. The interference of the curve is conceivable on the off chance that the bend stays in a diffused state. On the off chance that it is immediately taken out from the contact surface, the arc segment will be re-strike.

Arc segment termination in vacuum breakers is enormously affected by the material and state of the contacts and the strategy of thinking about metal fume. The way of the circular segment is continued to move with the goal that temperature at any one point won’t be high.

After the last arc segment interference, there is a quickly developing of dielectric fortitude which is impossible to miss of the vacuum breaker. They are reasonable for capacitor exchanging as it will give a re sans strike execution. The little current is intruded on before regular current zero, which might cause hacking whose level relies upon the material of contact.

Advantages

- Vacuum offers the most extreme protecting strength. So it has very superior arc extinguishing properties than some other medium.

- The vacuum Circuit Breaker has a long life.

- Dissimilar to Oil Circuit Breaker (OCB) or air blast Circuit Breaker(ABCB), the blast of VCB is kept away from. This improves the wellbeing of the working staff.

- No fire danger

- The vacuum CB is quick in activity so great for shortcoming clearing. VCB is reasonable for rehashed activity.

- Vacuum circuit breakers are nearly support free.

- No fumes of gas to the environment and Silent activity.

Disadvantages

- The fundamental inconvenience of VCB is that it is uneconomical at voltages surpassing 38 kV.

- The expense of the breaker becomes over the top at higher voltages. This is because of the way that at high voltages (over 38 kV) multiple quantities of the electrical switch are expected to be associated in series.

- Besides, VCBs creation is uneconomical whenever delivered in little amounts.

Applications

The Vacuum Circuit Breaker is today perceived as the most dependable flow interference innovation for medium voltage switchgear. It requires least upkeep contrasted with other Circuit Breaker innovations.

The innovation is essentially reasonable for the most part medium voltage applications. For higher voltage vacuum innovation has been grown, yet it isn’t monetarily plausible. Vacuum circuit breakers are utilized in metal-clad Switchgear and furthermore in porcelain housed circuit breakers.

HDVC (High Voltage Direct Current) Circuit Breaker

HVDC(High Voltage Direct Current) circuit breaker is a unique type of circuit breaker that is explicitly intended to use for protection against fault current in a HVDC circuits.

As we discussed earlier, the major significant part that separate the DC circuit breaker from other type of breakers is the arc extinguishing technique. In AC breaker, it is simpler to break the circuit at zero intersection on the grounds that the energy by then is zero which doesn’t permit producing arc at that voltage level. While in DC, the voltage and current never goes to zero. So there is in every case extremely high voltage and current between the contacts during its separation.

Based on Operations

- Dead Tank Circuit Breaker

- Spring-Operated Circuit Breaker

- Pneumatic Operated Circuit Breaker

Dead Tank Circuit Breaker

A dead tank circuit breaker is a type of circuit breaker utilized in high-voltage power system to hinder or break the flow of electrical current in case of a shortcoming or unusual condition. The expression “dead tank” alludes to the plan of the circuit breaker, where the intruding on component is situated in a grounded tank or nook, rather than a live tank circuit breaker where the interrupter is mounted in a protecting bushing that reaches out into the high-voltage equipment.

Here is a clarification of the critical parts and activity of a dead tank electrical switch:

- Tank: The fundamental part of a dead tank electrical switch is the grounded metal tank or nook that houses different parts. This tank gives electrical protection and insurance from outside ecological variables.

- Interrupter Assembly: The interrupter gathering is the core of the circuit breaker and is liable for interfering with the electrical flow when a shortcoming happens. It commonly comprises of fixed and moving contacts isolated by a protecting medium, for example, sulphur hexafluoride (SF6) gas or vacuum. At the point when the breaker is shut, the contacts are in electrical contact, permitting flow to stream. At the point when now is the right time to open the circuit, the contacts move separated, making a curve. The interrupter’s job is to rapidly smother this circular segment to forestall harm to the gear and keep up with electrical well-being.

- Control and protection System: Current dead tank circuit breakers are frequently outfitted with complex control and security frameworks. These frameworks screen the electrical boundaries of the circuit and give insurance against different deficiencies, for example, over-current, short-circuits, and over-voltages. They can likewise empower distant activity and give demonstrative data about the circuit breaker’s status.

- Working Instrument: A dead tank electrical switch is furnished with a working component that controls the opening and shutting of the circuit breaker. This instrument can be physically worked or engine driven, contingent upon the application. It gives the essential power to move the contacts and make the fundamental leeway to smother the bend during opening.

- Grounding System: Since the tank is grounded, it serves to securely disperse any short-circuit current that could move through the fenced in area, decreasing the risk of electrical hazards.

The activity of a dead tank circuit breaker can be summed up as follows:

- Closing: At the point when the circuit breaker is closed, the contacts connect, permitting current to flow through the circuit.

- Opening: At the point when a short circuit or strange condition is identified, the working instrument moves the contacts separated. This activity makes an arc between the contacts. The interrupter gathering then, at that point, attempts to rapidly extinguish and quench the arc, hence intruding on the ongoing current flow.

Spring-Operated Circuit Breaker

A spring-operated circuit breaker, or also called as a spring-loaded circuit breaker, is a kind of circuit breaker that utilizes mechanical springs to control the opening and closing of electrical contacts inside the breaker. These circuit breakers are generally utilized in low-voltage and medium-voltage power distribution systems. This is the way they work and a few key characteristics:

- Working Mechanism: At the center of a spring-worked circuit breaker is a working instrument that incorporates at least one strong mechanical springs. These springs are regularly preloaded or charged when the electrical switch is in the shut position. The put away energy in these springs empowers the electrical switch to open rapidly when a shortcoming or over-burden is recognized.

- Opening Operation: At the point when a shortcoming or over-burden condition happens in the electrical circuit being safeguarded, an outing signal is shipped off the electrical switch. This sign deliveries the hook or lock, permitting the put away energy from the springs to quickly drive the contacts to open. The quick partition of the contacts smothers any curve that might have shaped because of the shortcoming, interfering with the electrical flow.

- Closing Operation: At the point when the electrical switch is physically or electrically shut, the working component draws in a hook or lock to keep the contacts in the shut position. The energy from the charged springs is put away, prepared for use.

- Arc Interruption: Spring-worked circuit breakers might integrate circular segment dousing instruments, for example, curve chutes or attractive victory curls, to help extinguish and cool the electrical bend that structures when the contacts open. This further develops the electrical switch’s capacity to hinder high-flow blames securely.

- Resetting: After the fault is cleared and the circuit breaker has opened, the springs should be re-energized or reset for the circuit breaker to be prepared for the following activity. Contingent upon the plan, this reset interaction might be manual or programmed.

Pneumatic Operated Circuit Breaker

A pneumatic operated circuit breaker is a sort of circuit breaker that uses compressed air or other pneumatic (gas) mediums to control the opening and closing of electrical contacts inside the breaker. These circuit breakers are regularly utilized in modern and utility power system, especially in medium and high-voltage applications.

Pneumatic Operating Mechanism

The center part of a pneumatic worked circuit breaker is its pneumatic working system. This system comprises of a chamber loaded up with compacted air or another gas. It is liable for controlling the development of the contacts inside the circuit breaker.

Pneumatic worked circuit breakers are usually found in substations and power appropriation frameworks where solid and fast interference of electrical flaws is fundamental for keeping up with the trustworthiness of the electrical matrix. They give a reasonable option in contrast to other electrical switch advances like oil circuit breakers or vacuum circuit breakers, especially in applications where pneumatic frameworks are now being used for different purposes.

Gas Circuit Breakers

- Sulphur Hexafluoride (SF6) Circuit Breaker

Sulphur Hexafluoride (SF6) Circuit Breaker

The SF6 Circuit Breaker or Sulphur Hexafluoride is one sort of Circuit Breaker (CB) that utilizations compressed SF6 gas to extinguish the arc segment. SF6 is a dielectric gas that has the properties like arc segment extinguishing and predominant protecting. It is mainly utilized for extinguishing the arc inside high voltage CBs in electrical grids and power stations up to 800 kV.

The SF6 Circuit Breaker working time primarily varies in view of the makers, however the regular working time is around 18 – 20 seconds. SF6 Circuit Breaker voltage range is 800 kV in electrical systems and 35 kV in distribution systems.

When a arc is struck among the contacts of an Circuit Breaker, then it retains the free electrons from it and changes into negative particles. When contrasted with electrons, these are heavier. In view of the significant burden of the particles, their versatility can be diminished. In SF6 gas, the versatility of the charge has less portability which builds the dielectric force of the medium on the grounds that the development of the charge is answerable for the progression of flow.

Construction

The SF6 Circuit Breaker incorporates two fundamental parts basically the interrupter unit and the gas system.

Interrupter Unit

In the SF6 circuit breaker, the interrupter unit incorporates fixed and moving contacts that are encased inside a chamber. Here, the decent contacts are not versatile while the moving contacts will move back and forward through an arm enacted by a component.

Here, this chamber is known as the arc interference chamber which incorporates SF6 gas. The association of this chamber should be possible straightforwardly associated with the SF6 gas repository where a valve instrument permits the SF6 gas toward the arc interference chamber.

The decent contact is an empty tube shaped contact that is associated through an arcing horn while the moving contact can likewise be an empty chamber through rectangular openings inside the sides. These openings permit the SF6 gas to let out all through them once streaming along &across the arc.

The contacts like fixed and moving and arcing horn are covered through a copper-tungsten material. SF6 gas is costly; it is cleaned and recovered through the auxiliary system after each circuit breaker operation.

Gas System

The SF6 gas is expensive and its item gases outflow is risky for the environmental factors. In this way, a closed gas system is used, any place the used SF6 is recombined for going back over. Its strain is likewise kept up with as its dielectric strength significantly relies on it. At the point when the gas pressure is extremely high, then care ought to be removed to keep from the gas leakage at joints by giving ideal scaling.

At the point when the tension of a gas is incredibly high, then, at that point, more consideration care to be taken to keep away from the leakage of gas at joints by offering ideal scaling.

The association of both the low and high-pressure frameworks should be possible through low-pressure-based cautions and a few lockout switches which give a notification when the gas pressure diminishes under a specific worth in any case the dielectric strength is decreased and arc extinguishing limit of the electrical switch will be endangered.

The SF6 gas can be put away inside the high-pressure chamber at 16 ambiances though the strain of the gas on the less tension side is three ambiance. The 20◦C temperature is utilized to keep away from liquefaction of SF6 gas inside the high-pressure chamber. A radiator is associated at less temperature inside the high-pressure chamber. When the surrounding temperature decreases under 16 degrees Centigrade, then an indoor regulator is associated with switch ON.

Working

In generally, the Circuit Breaker contacts are closed in typical working circumstances. When the mistake or fault happens inside the system, then at that point, Circuit Breaker contacts will be pulled independently and a arc is struck among them. The moving contacts uprooting can be synchronized through the valve which enters the high-pressure gas inside the intruding on office of curve at 16kg/cm2 pressure.

The SF6 gas draws in the free electrons inside the bend path to frame particles where particles don’t perform like a charge transporter. These Particles will upgrade the strength of the dielectric of SF6 gas, subsequently the circular segment can be doused. Thus, this technique will diminish the power of the gas up to 3kg/cm2 so; it is essentially put away inside the less tension supply.

This less pressure SF6 gas is pulled back to the supply to utilize once more. Presently, puffer cylinder force is used essentially for creating the strain of bend extinguishing all through an initial cycle other than a cylinder associated with the moving contacts.

Advantages

- The advantages of the SF6 circuit breaker incorporate the following.

- The property of SF6 gas is arc extinguishing that is multiple times compelling when contrasted with air.

- Extremely short arcing time.

- Dielectric strength is high a direct result of electronegativity.

- Enormous flow can be intruded on due to high dielectric strength.

- Configuration is minimal

- It has a compact design.

- Requires low maintenance

- It handles a wide range of switching.

- This CB incorporates a shut circuit gas framework through no spillage. In this way, it very well may be associated in an extreme climate.

- Noiseless operation.

- SF6 gas isn’t combustible and nontoxic

Disadvantages

- When contrasted with oxygen, the SF6 is heavier.

- These Circuit Breakers are costly

- SF6 spillage should be observed.

- It needs extraordinary transportation.

- Reconditioning and recombination of this gas needs additional equipment.

Applications

- These CBs are utilized to safeguard exceptionally high voltage-based circuits up to 800 kV.

- It can depower and break a high voltage-based circuit for an upkeep and review.

- These CBs safeguard circulation frameworks and power transmission. These are utilized in power networks and power age plants.

- Power Distribution and control.

- Utilized in power circuits for Line protection.

- Utilized in rectifier and capacitor circuits

- Utilized in transformer protection.

Conclusion

In this article we have discussed the various types of circuit breakers in detail. The principal capability of the circuit breaker is to break a circuit in some fault conditions like a short circuit, over-current, and so on. There are many more types of circuit breakers, but we have discussed the important one.

FAQs on Types of Circuit Breakers

1. Why SF6 is used in Breaker?

The reasons to utilize SF6 gas in circuit breakers are non-combustibility, high electrical insulating properties, non-toxicity, competitive cost and low maintenance.

2. When would you use a vacuum circuit breaker?

Vacuum Circuit Breakers are essentially utilized where system voltage levels are up to 72 kV.

3. What is the pressure of SF6 gas in the circuit breaker?

The pressure of SF6 gas in Circuit Breaker is about 2.8 kg/cm2

Share your thoughts in the comments

Please Login to comment...