Automation Systems

Last Updated :

01 Nov, 2023

Automation systems play a pivotal role in various industries by simplifying and streamlining processes, reducing human intervention, and improving efficiency. Automation systems, also known as industrial automation systems, are a set of hardware and software components designed to operate and monitor industrial processes, machinery, and equipment with little or no human intervention. In manufacturing and other industrial contexts, these systems play a critical role in increasing efficiency, improving output, improving product quality, and assuring safety.

What is an Automation System?

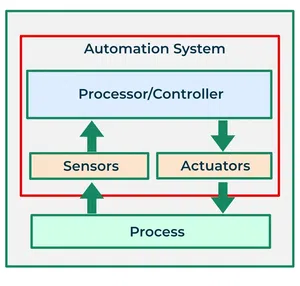

Automation System

An Automation System is a comprehensive solution designed to perform tasks and processes with minimal human intervention. It integrates hardware and software components to achieve efficiency and consistency in various industrial and non-industrial applications. Automation systems can encompass a spectrum of technologies, from simple programmable logic controllers (PLCs) to complex robotic systems. They are employed in manufacturing, automotive, and logistics industries to streamline operations, reduce labor costs, and improve product quality.

Important Terminologies Related to Automation Systems

Before diving deeper into automation systems let’s clarify some essential terminologies:

- PLC (Programmable Logic Controller): A specialized digital computer used to control various electromechanical processes in the industrial environments.

- SCADA (Supervisory Control and Data Acquisition): A system used to monitor and control industrial processes and equipment.

- HMI (Human-Machine Interface): A graphical user interface that allows users to interact with the automation systems.

- Sensors: The Devices that detect physical properties like temperature or light and provide data to control system.

- Actuators: Components that carry out actions based on control system commands such as motors or valves.

Types of Automation Systems

1. Fixed Automation Systems

The Fixed automation systems is known as hard automation are designed for the dedicated tasks. They are ideal for high-volume production of identical products. Examples include assembly line robots in automotive industry.

2. Programmable Automation Systems

The Programmable automation systems offer flexibility by allowing the reprogramming of tasks for the different product variations. They are commonly used in the industries where product changes occur frequently like consumer electronics.

3. Flexible Automation Systems

The Flexible automation systems combine the advantages of fixed and programmable automation. They can handle varying tasks with the minimal setup changes. The Flexible manufacturing systems (FMS) fall into this category.

4. Integrated Automation Systems

The Integrated automation systems connect multiple processes and components into unified system. These systems are prevalent in smart factories and Industry 4.0 initiatives. where data exchange and analysis are crucial.

Basic Components of Automation Systems

The Automation systems comprise several fundamental components including:

Basic Components of Automation System

1. Sensors

The Sensors collect data from the environment such as temperature, pressure or position. They provide critical input for the decision-making in automation processes.

2. Controllers

The Controllers often based on PLCs or microcontrollers execute control algorithms based on sensor inputs. They determine the actions of the other system components.

3. Actuators

The Actuators are responsible for physical actions such as moving a robotic arm or opening a valve. Electric motors and hydraulic pistons are common types of the actuators.

4. Human-Machine Interface (HMI)

The HMIs allow human operators to interact with the automation system. They provide visual feedback, control options and monitoring capabilities.

Components of Automation System

An automation system typically consists of hardware components like sensors, actuators and an HMI. The software component involves programming logic and control algorithms that govern system behavior. Communication protocols ensure data exchange between the components.

- Sensors: Detect physical changes and provide data.

- Actuators: Execute actions based on the control signals.

- PLC: Control unit that processes data and commands.

- HMI: Interface for the human interaction.

- Control Algorithms: Software for the decision-making.

- Communication Protocols: Enable data exchange.

End-Of-Arm-Tools (EOAT)

End-of-arm tools, or EOATs are essential components of the robotic automation systems. They are specialized attachments mounted at the end of robotic arms to perform the specific tasks such as gripping, welding or painting.

Working Principle of Automation Systems

The working principle of an automation system depends on the type and application. For instance in a manufacturing assembly line sensors detect the position of components controllers analyze the data and actuators execute precise movements to assemble products. An automation system operates on the premise of using hardware and software components to control and monitor numerous processes or tasks with minimal human intervention. The fundamental purpose in industrial or other applications is to improve efficiency, productivity, safety, and consistency.

Construction of Automation Systems

The construction of automation system varies based on its purpose. It typically involves assembling sensors, controllers and other components into a cohesive and efficient configuration. Automation systems continue to revolutionize industries and driving innovation and efficiency. Understanding their component and applications is crucial for businesses seeking to leverage the advantages of automation in a rapidly evolving technological landscape.

The design, build, and implementation of automation systems is a systematic process that combines numerous hardware and software components to create a system that can control and monitor industrial processes or tasks with minimal human interaction. The following are the major steps in the construction of automation systems:

- Define your goals and requirements : Define the automation system’s aims and goals clearly. Determine which jobs or processes must be automated. Determine the requirements, such as performance standards, safety standards, and regulatory compliance.

- System Development : Create a detailed system design that outlines the automation system’s architecture. Determine the hardware and software components required. Create a functional specification outlining how the system will work, including control logic, user interfaces, and communication protocols.

- Hardware Selection and Integration : Choose the right hardware components for your automation system, such as sensors, actuators, PLCs, HMI panels, industrial PCs, and networking equipment. Ensure that different hardware components are compatible and integrated.

- Software Creation : Create control software for programmable logic controllers (PLCs), microcontrollers, and other control devices. Control logic, algorithms, and user interfaces must be implemented exactly as described during the design process. Before deploying the software, it should be tested in simulation environments.

- Installation of Sensors and Actuators : Install sensors to get information from the physical world. Sensors should be calibrated and configured as needed. Connect actuators to the system so that they can respond to control signals.

- Debugging and testing : Test the automation system thoroughly to discover and resolve any software or hardware faults. Test the system using simulations and, if possible, actual processes or equipment.

Advantages of Automation Systems

- Increased Efficiency: The Automation systems can work continuously without breaks or fatigue.

- Improved Accuracy: Reduced human error leads to the higher precision and quality.

- Enhanced Safety: The Dangerous tasks can be performed without the risking human lives.

- Cost Reduction: Labor and operational costs decrease with the automation.

- Scalability: The Systems can adapt to changing production demands.

- Data Collection: The Automation systems provide valuable data for the analysis and optimization.

Disadvantages of Automation Systems

- High Initial Cost: Implementing automation can be expensive.

- Technical Challenges: Designing and maintaining automation systems require the specialized skills.

- Job Displacement: The Automation may lead to job losses in certain industries.

- Limited Adaptability: The Complex tasks or rapid changes may challenge automation.

- Dependence on Electricity: The System failures or power outages can disrupt operations.

- Security Risks: The Automation systems can be vulnerable to cyberattacks.

Conclusion

Automation systems are a critical part of modern industries offering numerous advantages such as efficiency and cost savings. However, they also come with the challenges including the high initial costs and job displacement. The Careful planning and implementation are key to maximizing the benefits of the automation. Finally, automation systems are critical in current industrial processes and operations. They are intended to improve efficiency, productivity, safety, and quality by decreasing the need for human interaction and enabling precise control over numerous jobs and processes.

FAQs on Automation Systems

Q1. What is the main purpose of automation systems?

Answer:

The Automation systems aim to perform tasks and processes with the minimal human intervention and improving efficiency and quality.

Q2. What are the key components of an automation system?

Answer:

The Key components include sensors, controllers, actuators, HMIs and software.

Q3. How do automation systems enhance productivity?

Answer:

They operate continuously reducing downtime and perform tasks with the precision leading to the higher output levels.

Share your thoughts in the comments

Please Login to comment...