PLC stands for Programmable Logic Controller which was invented in automobile manufacturing to provide a flexible, rugged, and easily programmable controller to automate a system in the year of 1964 by Dick Morely. That’s why he is called as father of PLC. The first PLC was Medicon 084. These PLCs were large, expensive, and not easy to maintain and program. That’s why in the next generation it was upgraded to medium and small size PLCs. It is a hardware device with microprocessor-based control system. PLC is a general-purpose computer modified specially to perform control tasks. It is used for industrial automation to automate a specific process, machine function, or even entire production. PLCs are developed for electronic replacement for hard-wired relay logic circuit systems for machine control. They are designed for industrial use to control many automated processes in industries.

In this Article, We will go Through what is a Programmable Logic Controller and how a programmable logic controller works, We will go through Different types of PLC, Then we will proceed with PLC programming Examples and see industrial PLC programming examples, At last, we will conclude our Article with its Applications, Advantages, Disadvantages and Some FAQs on PLC.

What is a Programmable Logic Controller (PLC)?

A programmable Logic Controller(PLC) is a specialized digital computer employed in industrial settings for automation and control. Acting as the central brain of machinery and processes, PLCs receive input from sensors, process the data through programmed logic, and generate output signals to control devices like motors and valves. They use a programming language, often ladder logic, resembling electrical relay diagrams. PLCs are ruggedized for harsh industrial environments and play a crucial role in automating tasks and reducing manufacturing and energy. Their modular design allows scalability, making them versatile components in modern industrial control systems.

Where Can PLC Be Used?

PLCs play a pivotal role in industrial automation, efficiently managing machinery and processes. They receive data from sensors, execute programmed logic, and control actuators, enhancing precision and reducing manual intervention. PLCs find application across diverse industries, from manufacturing to utilities, ensuring streamlined operations, increased productivity, and adaptability to evolving production needs. Their robust capabilities make PLCs indispensable in modern industrial settings, facilities with seamless control and automation for improved efficiency and reliability.

Main Components of a PLC

Their are mainly 6 major part of a PLC that are :

- Processor

- Memory(RAM/ ROM)

- Input device

- Output device

- Power supply

- Programming device

Description of each part of a PLC :

- CPU : CPU is the brain of a PLC, responsible for executing the control program stored in memory. It performs tasks such as data processing, decision-making and communication with other devices.

- Memory(RAM/ROM) : PLCs have main type of memory one is ram and another is rom. RAM is used for storing data and variables temporarily during the execution of the program. ROM is used to store the operating system of a PLC and the user program. The program typically consists of two ladder logic, function block diagrams or other programming languages.

- Input Device : This is responsible for interacting with the machine and the instructor which can be external sensors, switches etc. This part helps to take input and send to to the CPU to response accordingly.

- Output Device : Output device is responsible for interacting with the end point external device like motor, valve or indicator. It converts control signal from the PLC that these devices can interpret.

- Power Supply : PLC requires a stable power supply to run its program and match the voltage levels that needed for a PLC components.

- Programming Device : As PLC is mainly a programmable device, so we need a device where we can write code and execute it, just like a monitor and keyboard.

Basic Structure of PLC with Block Diagram

Structure-of-PLC

Working of PLC controller

- Their are main four part of a PLC, input and output module, controller and a power supply.

- First supply current goes to the power supply machine which is 220v AC, later it is divided into three parts and converts it from AC to DC. Both of the two input and output module takes 24v DC current and the main controller part takes 5v DC current.

- Input part takes signal from sensor and other devices, and passes it to the PLC main part.

- The main controller part sends the signal to the CPU, then starts executing its program in compiler from the memory. After that the program creates a instruction signal, which goes to the output module.

- The output module receives type signal and sends it to the external devices like motor, valve etc. which will execute the instruction by controlling the system according to the instruction.

This part can continue in a loop cyclically. For one single cycle this whole process is called scan time of PLC.

Working-of-PLC-Controller

Types of PLC

PLCs can be classified into three main types based on their capabilities :

- Compact PLC : compact PLCs are small size and typically have a limited number of I/O points. They are designed for space is a critical factor, and the control requirements are relatively simple. Compact PLCs are often used in small-scale control applications where the number of devices to be controlled and monitored is limited. Examples include simple machines, standalone equipment, or processes with minimal complexity.

- Modular PLC : Modular PLCs are designed with s modular architecture, where the CPU, Power supply, and input-output modules are separate components. This modular designed provides flexibility in system configuration, making it easier to expand or modify the system based on changing requirements. Modular PLCs are suitable for applications that may grow or change over time. Industries with evolving control needs, such as manufacturing plants that may expand production lines.

- Rack-Mount PLC : This is a type of High end PLC which is specially designed for complex and demanding application. It has maximum number of I/O points also Rack-mount PLCs are modular and can easily expanded by adding additional modules to the rack.

Compact and Modular PLC

Features of PLC

PLC comes with a wide range of features, which makes it versatile. The features are :-

- Digital and analog I/O : It can handle both digital and analog signals from the sensor and other input device and allows a wide range of input.

- Scalability : Many PLCs offer modulation in their setting by expanding the input/output number or CPUs to accomodate the changing requirements.

- Communication interfaces : PLCs support various communication devices and protocol like ethernet, modbus to devices like CPU monitor and control systems.

- Programming Language : It allows different programming languages like ladder logic, structured text, function block diagram etc. to the user.

- Real-Time monitoring : PLCs operate in real-time by continuously scanning and processing input signals to make rapid decisions and update output devices with minimal delay.

- Mathematical Functions : PLCs support mathematical functions and calculations. enabling users to perform computations within the control program.

Applications of PLC

- Manufacturing Automation: PLCs are extremely used in manufacturing industries for automating processes such as assembly lines, packaging, and material handling.

- Process Control : In industries like chemical, petrochemical, and pharmaceuticals, PLCs play a crucial role in controlling and monitoring complex process.

- Water treatment and Distributions: PLCs are employed in water treatment plants to control the purification process, monitor water quality, and manage the distribution of water in a network.

- Food and Beverage Industry : PLCs can be used in food processing plants for tasks like mixing, backing packaging, quality control etc.

- HVAC System : PLCs play vital role in heating, ventilation, ACs to managing temperature, humidity, air quality etc.

PLC Scope in Future

The PLC will evolve in future as it has a vast application and use in industry while it can enhance its communication between hardware and software. We can expect to see smaller and more compact PLCs with more work power with small micro and mini USB connecter.

PLCs are expected to play a crucial role in industry 4.O revolution, which focuses on the integration of digital technologies, the IOT, cloud computing and AI in industrial automation. We can see adoption of protocols like OPC UA for standardized communication, Inter-corporation of edge computing for faster data processing.

Programmable Logic Controller Programming

PLC is a programmable controller. We can create logic through programming to control a system. Their are several types of programming languages or strategies that can be followed. Some of them are :-

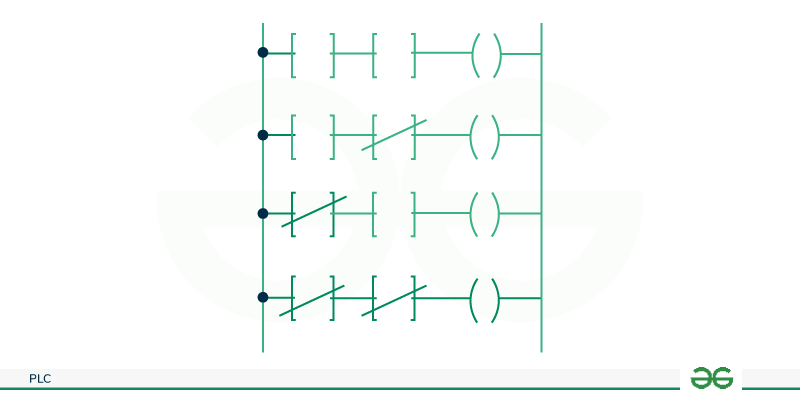

- Ladder Logic : Ladder logic is also known as Ladder diagram. It is basically a graphical representation of relay logic circuit, which consists two vertical parallel lines connected by horizontal lines. This lines are called rail and rungs. the vertical line works to supply power, and the vertical line is responsible for creating logic.

Ladder Logic

- Function Block Diagram : Function Block Diagram(FBD) in PLC programming is a graphical representation of control logic. It uses function blocks to depict operations, such as comparisons or timers, with inputs and outputs conducted by lines. Contacts and coils symbolize input conditions and output actions. Branches and junctions control logic flow. For instance, motor control system FBD might include a start or stop button, a motor and a control relay illustrating the interconnection of these components in a visual and intuitive format for programming complex control algorithms.

Function-Block-Diagram

Examples of PLC Programming

Lets program an AND logic for PLC using ladder logic :

Truth Table

|

A

|

B

|

Output(A.B)

|

|

0

|

0

|

0

|

|

0

|

1

|

0

|

|

1

|

0

|

0

|

|

1

|

1

|

1

|

Now from this truth table we will try to program it using ladder logic. In ladder logic there are two switches, NO(normally open) means it will not pass any signal and NC(normally closed) means it will pass signals. And there is a output terminal. Switches are connected with a vertical line, which is called rung, and those rungs are connected to the supply line, which is vertically, call rails. Rungs are also connected to output terminals to get output signals.

Here 0 means no current is passing, means we will use a NO switch for exact 0, and 1 means current or signal is passing, we will use a NC switch for that. and will se what is the output, and will check it with the truth table.

Ladder-logic-diagram-of-AND-gate

In the first three horizontal line, the output is 0, means no signal or current is coming, because at least one of the switch is NO. In the last rung the output is 1, means it passes current or signal. This is how we generally program a PLC.

Advantage and Disadvantages of PLC

Some of the advantages and disadvantages of PLC are:

Advantages

- Flexibility and Reliability : PLCs are highly flexible. They can be easily programmed and edited. Manufacturing process of PLCs can be done virtually, without physical presentation. It makes PLC more flexible. They are made for robust condition, which makes it more reliable for industry.

- Programming : PLCs are programmable device. Which means it can be edited. The code and the instructions given to it are easily changeable.

- High Speed Operation : Because of being a programming device, it can create instant output instruction, which depends on the program complexity and the CPU memory, makes it more efficient.

- Monitoring system : PLCs provide inbuilt monitoring tools, make them easier to identify the troubleshoot in the system.

Disadvantages

- Cost : Initial investment for installation for a PLCs are costly. Mainly for small business it can be costly.

- Programming : Ladder logics are comparatively easy but complex control system may require extensive algorithm and program.

- Software update : It is quite challenging to maintain and upgrade when older PLC system become obsolete or when software hardware updates are required.

- Scalability issue : Some PLC system may face scalability issues, particularly if the initial design did not account for future expansions or changes in the manufacturing process.

Conclusion

Programmable Logic controller or PLC in short stand at the forehead of industrial automation. PLCs have emerged as indispensable tools in the realm of industrial automation, playing a pivotal role in enhancing efficiency, precision, and flexibility across diverse manufacturing processes. Over the years, PLCs have evolved from simple relay based control system to sophisticated programmable devices capable of executing complex tasks. Their adaptability, reliability and scalability make them integral components in various industries, including manufacturing, energy and process automation.

Furthermore PLCs have proven instrumental in reducing downtime and maintenance costs, as their modular nature allows for swift replacement of faulty components. The continuous advancements in PLC technology, including the integration of communication protocols and connectivity with other smart devices, position them at the forefront of the fourth industrial revolution.

FAQs on PLC

What is PLC ?

PLC or Programmable logic controller, is an industrial digital computer designed to control manufacturing process, machinery and other control system.

How PLCs are integrated with other automation systems ?

PLCs can be integrated with other systems, such as SCADA, through communication protocols like Modbus or OPC to provide a comprehensive and centralized control solution.

Can PLC programs be edited or modified ?

Yes. PLCs can be edited and modified easily, allowing for flexibility in adapting to changes in the manufacturing process.

What are the primary components of a PLC ?

A typical PLC system includes a CPU, memory, input and output modules, programming device and power supply.

Share your thoughts in the comments

Please Login to comment...