VRM stands for Voltage Regulator Module. VRM acts as dedicated power stations for sensitive electronic components such as Smartphones, TVs, and Servers. By Ensuring they receive the lower voltage they require. Think of them as miniaturized power grids, adapting the main power supply to the specific needs of each component.

VRM plays an important role in various electronic devices, including computers, tablets, and even power supplies. They are responsible for improving efficiency, stable voltage, and flexibility.

What is a VRM?

A VRM is a special circuit that converts the input voltage to stable voltage which is required by delicate components like CPU and GPU. For example, a city with different buildings requires specific amounts of electricity. A VRM acts like a dedicated power station for sensitive electronic components, ensuring they receive the lower voltage they need to function properly. It’s like a voltage controller where each component gets its specific power to function optimally.

Most commonly, VRMs are found on motherboards, CPU, and GPU which are used to regulate the power supply or stabilize input voltage. They are also found in other electronic devices such as laptops, phones, networking equipment servers, etc.

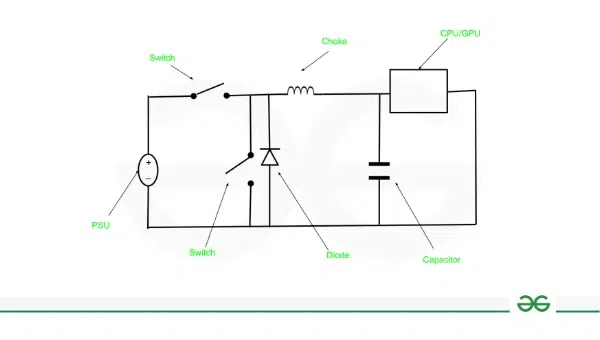

Circuit diagram of VRM

How does a CPU and GPU uses VRM?

CPU(Central processing unit) and GPU(Graphics processing unit) are brains of the computer which are responsible for calculations, graphics rendering and certain operations respectively.

When they not receive specific voltage, they can cause damage. For the high performance of CPU and GPU we require a specific voltage. VRM(voltage regulator module) plays a major role for providing a stable voltage to the CPU and GPU.

- CPU and GPU Needs: CPU and GPU operate at lower voltages when compared to the standard 12V provided by the power supply. VRM decrease this voltage and provide a specific voltage which is required by the CPU and GPU. Sometimes, fluctuations in voltage leads to damage, instability and crashes the system depending on workload. VRM prevents this by acting as voltage regulator, ensuring a stable and clean power supply.

- Action of VRM in CPU and GPU: VRM receives the voltage from main power supply(i.e., 12V). The CPU and GPU communicates with VRM controller by giving their voltage requirements through a special “VID” signal. VRM convert this higher voltage to specific voltage or stable voltage which is required by the CPU and GPU. This conversion is known as buck conversion which means the conversion of higher voltage to specific voltage. Inductors and capacitors within the VRM act as reservoirs, filtering out fluctuations and delivering a smooth, steady voltage.

- Benefits of using VRM in CPU and GPU: By regulating voltage, the VRM can protect the sensitive components in CPU and GPU from damage caused by the high load or fluctuations. VRMs reduces the heat generation and high power, by delivering required voltage. For CPU and GPU, VRM allow them to operate full potential by translating stable voltage for optimal performance.

So, VRM are the unseen heroes behind the computer performance and smooth operation of our computers CPU and GPU.

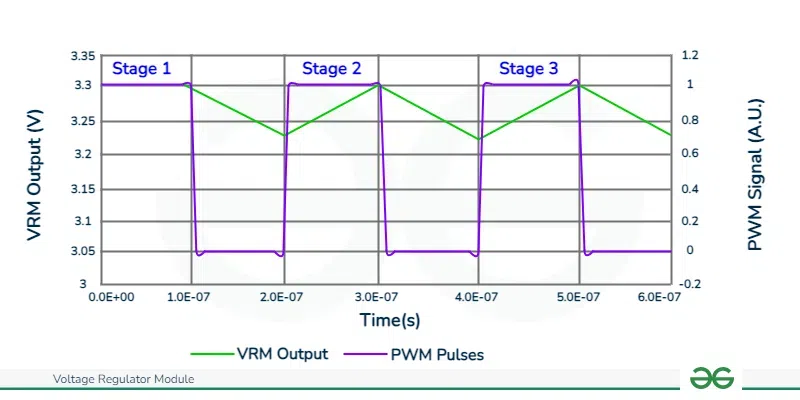

Working of VRM

A VRM acts like a dedicated power station for electronic components, ensuring they receive the lower voltage they need. It takes the main power supply voltage and changes it using a team of components: the controller, power stage, inductors, and capacitors.

Controller is the brain of the operation, it will continuously monitoring and adjusting the output voltage and it also receives voltage information from feedback circuit, forming a closed loop then the controller adjusted to maintain desired output voltage.

Capacitors and Inductors acts like a Reservoirs that stores the energy, delivers stable voltage and release energy quickly. By ensuring the VRM can respond to sudden changes in load, filtering out fluctuations. Power Stage is the muscle, where the conversion of actual voltage takes place. This closed-loop system ensures components get the right amount of power, leading to smooth operation, improved efficiency, and protection from damage.

Voltage Regulator Module

A variety of elements can affect their function, influencing parameters like effectiveness and dependability.

- Voltage Regulation Modules (VRMs) are engineered to manage a spectrum of input voltages while sustaining constant voltage output. If it operates outside this range, power dissipation could increase leading to diminished efficacy.

- The quantity of current the VRM needs (load capacity), also influences its performance level. Suitable load currents warrant that the VRM consistently supplies power during fluctuations in component requirements.

- For steady operation, swift transient response is essential for quick adjusting by the VRM according to varying load conditions; helping maintain stability with minimal changes in voltage levels across different loads served at various time points.

- Thermal management efficiency plays a crucial part in avoiding overheating risking reliable performances due particularly when thermal contexts impact operational efficiency.

Voltage Regulator Module

Types Of Voltage Regulator Models

VRMs are categorized into two types. They are

- Linear Regulators

- Switching regulators

Linear Regulator

Linear regulation employs linear transistor technology towards effective control over your requisite specifics and given large variations between desired outputs and available fed inputs correlatively high heat generations typical limiting application ranges.

It uses an active pass device such as MOSFET. Linear regulators are step-down convertors, so the output voltage is lower than the input voltage. Their simplicity and reliability makes them simple devices and cost effective.

There are few advantages in Linear regulators. Because of this advantages, the Linear regulators employs in various applications. Some if them are wearables, headphones and IOT devices etc., If the designers are interested for creating a low-cost application, Linear regulator is the best choice.

Switching Regulator

Switching regulators can be step-up, step-down convertors or combination of both, which is more efficient than linear regulator. It can achieve more efficiency depending on the requirements of the application. This is the main advantage of the switching regulator. It is useful in applications that need performance and efficiency, such as automotive applications and industrial etc.,

VRM Components and Design

VRM consists of a several Components they are Controllers, Capacitors, Inductors and power stage which is explained below:

Controller is the brain of the operation, it will continuously monitoring and adjusting the output voltage and it also receives voltage information from feedback circuit, forming a closed loop then the controller adjusted to maintain desired output voltage. Capacitors and Inductors acts like a Reservoirs that stores the energy, delivers stable voltage and release energy quickly.

By ensuring the VRM can respond to sudden changes in load, filtering out fluctuations. Power Stage is the muscle, where the conversion of actual voltage takes place. It contains a switching transistors such as MOSFETs and diodes. A circuit that sends voltage information back to the controller, forming a closed-loop feedback system for lower regulation.

VRM Components

Design Considerations of VRMs are efficiency, transient response, noise and thermal management which is explained below:

The arrangement of components, like buck (step-down) or boost (step-up), impacts performance and depends on the desired voltage and application. The speed at which transistors switch affects efficiency, noise, and component size. Finding the right balance is crucial.

Carefully chosen values for inductors and capacitors optimize efficiency, response time, and stability. Improper selection can lead to problems. VRMs generate heat, especially at high power. Effective heat sinks and airflow are essential for reliable operation and preventing damage.

Selection of VRM

There are some factors on which the selection of right VRM depends on such as efficiency, current and output voltage , however there are some guidelines to follow for the selection of the right VRM :

- Load Current Calculation: Maximum load current is calculated which can be handled by the VRM so for the reliable performance of the VRM – suitable current rating equipment are chosen. Accurate load requirements of the VRM combinatorial computational model remain crucial in ensuring optimal performances are reached within applicational contexts.

- Proper Voltage requirements: Input and output voltage rating is considered and then this helps to identify the appropriate VRM and applications.

- Efficiency Consideration: Incorporate efficiency-evaluation techniques with thermal-management into active use regulatory applications – minimizing losses, monitoring acute voltage fluctuations for potential real-time operative services registers .

- Datasheet Consultation: Regularly review datasheets and manufacturing recommendations to ensure compatibility criteria and represented performance charts inclusive descriptive captions.

Conclusion

For a steady and accurate voltage supply to microprocessors or other components in the system, VRMs are essential components for electronic devices. VRMs though often unseen and unappreciated, play a critical role in the world of electronics. By mastering concepts of VRMs, from their design and components considerations, we can empower their significance. This knowledge is important in various fields, from selecting the right VRM for your project to simply understanding the complicated power that takes place within your everyday devices.

FAQs on Voltage Regulator Module

What are the key components of VRM?

Controller, inductors, capacitors, power stage and feedback circuit are the key components of VRM.

What are some common problems with VRMs?

Overheating, overvoltage and instability etc., are some common problems in VRMs.

Do VRMs generate heat?

Yes, especially at high power levels. Proper heat management is essential.

Share your thoughts in the comments

Please Login to comment...