Types of RCM Approaches

Last Updated :

08 May, 2023

Introduction :

RCM (Reliability-Centered Maintenance) is a maintenance strategy that aims to improve the reliability and maintainability of physical assets in an organization.

Reliability Centered Maintenance (RCM) is a process that is used for determining overall maintenance in a system so that it can operate effectively in terms of cost, function, production availability, etc. without any failure interruption. It simply helps one to implement maintenance strategy that is both cost and equipment effective. RCM simply assign best maintenance strategies to individual assets so that it can reduce inefficiencies if present. RCM generally focuses on what can happen if root cause of failure is present in system. This simply makes it easier for one to assign appropriate strategy to each asset according to their priority and severity of failure.

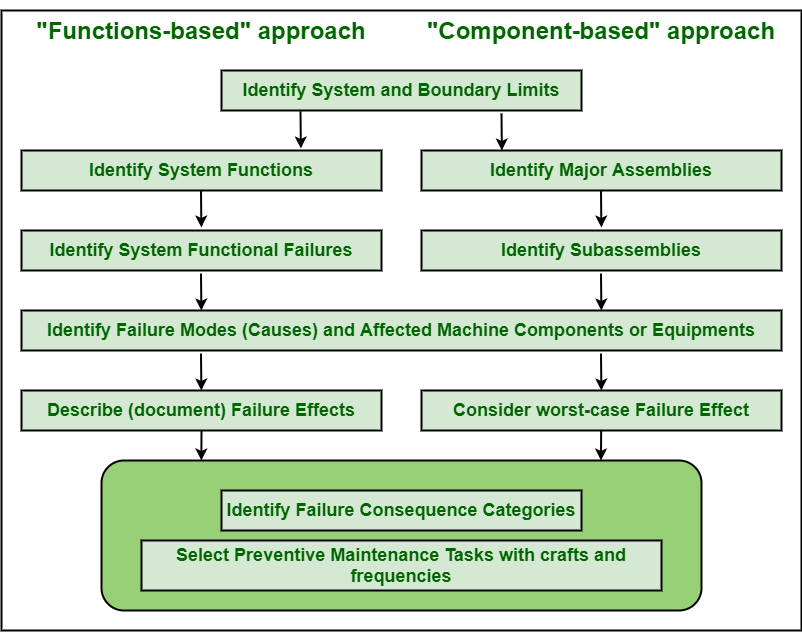

Types of RCM : There are basically two types of RCM techniques available nowadays. Selection of RCM technique is generally based on several factors as given below :

- Failure consequences.

- Probability of failure.

- Risk Tolerance.

- Availability of resources.

- Availability of historical data.

Two types of RCM techniques are as follows :

1. Classical RCM :

Classical RCM (Reliability Centered Maintenance) is a structured approach to develop maintenance strategies for complex systems and equipment. It was first developed in the 1960s by the United Airlines company for use in the aviation industry, but it has since been adopted by many other industries.

The classical RCM approach involves a detailed and systematic analysis process to identify potential failure modes of equipment and determine the most appropriate maintenance tasks to prevent or mitigate those failures. The process involves the following steps:

- System and Equipment Selection: Identify the system and equipment that will be analyzed.

- Function Analysis: Determine the function of the equipment and how it relates to the overall system.

- Failure Mode and Effects Analysis (FMEA): Identify all potential failure modes and their effects on the equipment and system.

- Criticality Analysis: Evaluate the impact of each failure mode on safety, operations, and economics.

- Maintenance Task Selection: Develop and select the most appropriate maintenance tasks to prevent or mitigate each failure mode.

- Task Optimization: Optimize the maintenance tasks to minimize costs while maintaining or improving equipment reliability.

- Implementation: Implement the maintenance plan and monitor its effectiveness.

The classical RCM approach requires significant resources and time to complete, but it is effective in improving equipment reliability, reducing maintenance costs, and ensuring safety and operational integrity. It is particularly useful for critical and complex equipment, where the consequences of failure can be severe.

Classical RCM is also known as Rigorous RCM. In this RCM technique, RCM creates list of all possible failure modes from rigorous assessment of all functions, considering all possible functional failures. After then an assessment of every failure mode that is being related to each functional failure. RCM then further focus on analyzing all possible failure mode on every asset i.e. equipment within system being analyzed. Rigorous RCM is slow process as it analyzes all possible failure modes separately. These techniques require rigorous documentation of functions, function failures, failure modes, failures effects. This approach is time-consuming as well as labor-intensive also. It is function-based approach.

2. Abbreviated RCM :

Abbreviated RCM is also known as Intuitive RCM, Streamlined RCM. We know that classical RCM is very time-consuming process and labor-intensive activity. There are various shortened versions of RCM being developed to speed up RCM Analysis or maximize overall value of time required for analysis. Therefore, such streamlined process is known as streamlined RCM techniques. It is a component and condition-based approach that does not require rigorous documentation. It simply considers hierarchical structure of equipment system and saves quarter of total analysis and implementation time. This RCM approach requires at least one individual that have full knowledge and understanding of different condition monitoring technologies.Abbreviated RCM (sometimes also called streamlined RCM) is a modified version of the classical RCM approach. It is a simpler and quicker process that is used for equipment that is less critical or lower in complexity. The abbreviated RCM approach still follows the same principles as classical RCM, but it involves a more streamlined analysis process that may skip some of the detailed steps of the classical approach.

The abbreviated RCM approach is often used in situations where time and resources are limited, and where the potential consequences of equipment failure are not as severe. It can be a cost-effective way to implement an RCM program for equipment that is not considered critical to the overall operation of the organization.

Despite its more simplified approach, the abbreviated RCM approach still involves a systematic and structured analysis process to identify potential failure modes and develop appropriate maintenance tasks to mitigate those failures. It may involve the use of decision trees, checklists, and other tools to guide the analysis process.

Uses of RCM Approaches :

Some of the common uses of RCM approaches are:

- Develop and optimize maintenance strategies: RCM approaches are used to develop and optimize maintenance strategies for complex and critical equipment. By identifying potential failure modes and selecting appropriate maintenance tasks, RCM helps to ensure that equipment operates reliably and safely while minimizing maintenance costs.

- Improve equipment reliability: RCM approaches help to improve equipment reliability by identifying potential failure modes and selecting appropriate maintenance tasks to prevent or mitigate those failures. This helps to minimize unexpected downtime and repair costs.

- Ensure safety and operational integrity: RCM approaches are used to identify potential safety hazards and develop appropriate maintenance tasks to prevent or mitigate those hazards. This helps to ensure that equipment operates safely and does not pose a risk to personnel or the environment.

- Reduce maintenance costs: By optimizing maintenance tasks, RCM approaches help to reduce maintenance costs by minimizing unnecessary maintenance activities and extending equipment life.

- Compliance with regulations: RCM approaches are often used to comply with regulatory requirements for equipment maintenance and safety. By following a structured and systematic approach, organizations can demonstrate compliance with regulatory requirements and avoid penalties and fines.

Share your thoughts in the comments

Please Login to comment...