Steps to Perform RCM

Last Updated :

11 Nov, 2020

Reliability Centered Maintenance (RCM) is a process that is generally used to optimize maintenance programs simply in order to preserve reliability and function of system. RCM is used more widely in all types of industries. We know that, at some time, equipment and machinery or systems fail. Therefore, one needs to obtain a suitable maintenance strategy. This maintenance strategy will help one to identify maximum probability of failure, all possible causes of failure, and then finally cost and time effective solutions or methods to preserve system from these failures.

RCM Process :

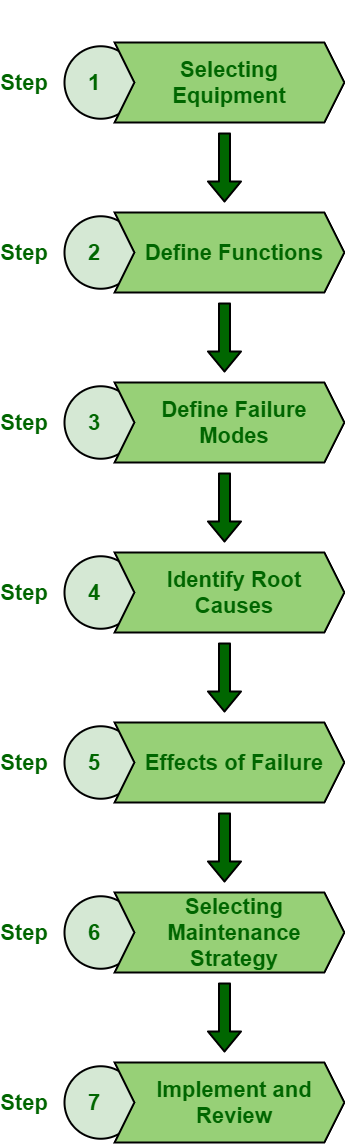

RCM process is completed in seven steps as given below :

- Selecting Equipment :

Initially, one needs to select an asset i.e. equipment, process, system, etc. that is needed to analyze. This selection should be done basis of its severity, cost required to repair it previously, maintenance cost, and impact on overall production and quality. After analyzing all these factors, one can select appropriate asset for RCM Analysis.

- Define Functions :

Secondly, one needs to define function of selected equipment. One should know how system works so that it can be handled accordingly. A system contains many equipment’s therefore it’s essential to know function of selected equipment so that appropriate maintenance strategy can be chosen.

- Define failure Modes :

Thirdly, one needs to identify different ways in which selected equipment and system can fail. Defining failure modes should be one of main objectives so that one can determine ways to preserve it before its occurrence.

- Identify root causes :

Fourthly, one needs to identify main causes of such failures so that failures can be removed permanently. Root causes are main reason for occurrence of such failures. It’s necessary to identify main causes of failure so that one can identify and implement effective solutions and maintenance strategies to eliminate failure permanently. Root causes can be determined using operators, experienced technicians, RCM teams, experts, etc.

- Effects of failure :

Failure can have greater impact on system. It can affect design, quality, process r application of system or equipment. A failure starts from its root cause and then lead to one particular end effect. It is very essential to identify how failure affects system, production, overall cost. It’s very necessary to determine criticality of failure before its occurrence. There are various techniques that can be used to identify effect of failure as given below :

- Failure mode and effect analysis (FMEA).

- Hazard and operability studies (HAZOPS).

- Fault tree analysis (FTA), etc.

- Selecting Maintenance strategy :

This step is very crucial and important. Identification of maintenance strategy is only way to preserve failure so it is very essential to choose appropriate maintenance strategy that must be cost-effective and reliable as well as technically feasible. There are two maintenance strategy i.e. condition-based maintenance and usage-based preventive maintenance. Maintenance strategy is chosen accordingly. If any failure mode does not have any maintenance options than only thing one can do is redesign system to eliminate and modify failure mode.

- Implement and Review :

RCM is a process that requires continuous improvement and maintenance. Therefore, after implementing maintenance strategy, one to review and check it on regular basis and should main continuous improvement. It should be reviewed regularly so that new updates can be implemented.

Like Article

Suggest improvement

Share your thoughts in the comments

Please Login to comment...