How to implement RCM?

Last Updated :

07 Dec, 2020

RCM (Reliability Centered Maintenance) is a process that helps one to identify failures or problems which when eliminated or resolved increases overall production of particular equipment as well as decrease maintenance cost. It is basically a method that helps one to determine which maintenance method will be the best for a particular piece of equipment that is being selected for RCM Analysis. RCM usually affects the bottom-line of the company in a very huge manner.

Implementing RCM :

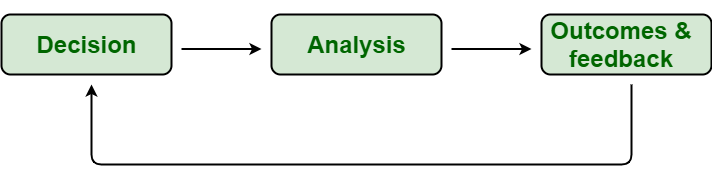

RCM is a somewhat complex process. To implement RCM, the process of RCM is divided into three different phases that simply ensure that RCM is fully implemented. Three different phases are given below –

- Decision Phase :

This is one of the important phases as in this phase, a decision is taken regarding which equipment will be put first under RCM analysis. A system consists of more than one piece of equipment. Each piece of equipment has some failure modes which might occur at any time. Some types of equipment have a less or limited number of failure modes and such system is considered simple systems whereas some types of equipment have many failure modes and therefore are considered complex systems.

In this phase, a decision is made regarding which equipment will be analyzed first on basis of the probability of failures and their severity. Some failures cause a greater impact on system safety, production, functions, operational cost, etc. Therefore, more crucial equipment is selected first that have large consequences of failure.

- Analysis Phase :

The next important phase is the analysis phase. In this phase, the main reason for the occurrence of failures is identified. In simple words, the main causes usually known as root causes of failure have identified that lead to the occurrence of such failures. One particular failure can have more than one root cause. So, it’s a very crucial step as one needs to identify all possible root causes of failure. Even if one root cause is not being identified by some mistake then it can lead to greater damage to the system.

RCM team and experts need to work together with full focus to identify root causes of failure. Root causes can be human error, design error, equipment failure, etc. One also needs to analyze and evaluate the impact or effect of failure on the system if somehow failure happens.

- Outcome and Feedback Phase :

The last phase is the outcome and feedback phase. After decision and analysis are done, one needs to take some measures actions to mitigate issues and improve equipment design. The decision regarding maintenance strategy is based on the above decision and analysis done by the RCM team and expert. RCM is a process that should be performed continuously, not only when it is needed to be performed.

RCM provides an opportunity for improving systems production and increasing quality by adding value to different organizations. It simply keeps the system more reliable and maintains the integrity of the equipment. RCM mitigates all possible failures that can occur and increases the lifetime of particular equipment as well as reduces maintenance cost also.

Share your thoughts in the comments

Please Login to comment...