Ward Leonard Method of Speed Control

Last Updated :

27 Feb, 2024

The Ward Leonard Method is a well-known (and reliable) electrical control system for controlling the speed of motors accurately. Leonard developed it in the early 20th century. Nowadays, It is widely used in various industries, particularly in applications where precise speed regulation is essential.

A system runs based on a motor-generator set and a rheostat in parallel. The main building blocks are a DC motor, a generator, and an adjustable resistor. The DC motor, i.e., the driving motor, drives the speed of the load motor by wobbling the voltage sent to it. The generator changes the electricity from the motor into DC and several variable resistors, (e.g. rheostat) or some devices adjust the current to reach the required speed.

One of the strong points of the Ward Leonard Method is the possibility of giving out precision speed control and a stable one that makes it appropriate for operations where accuracy and reliability are the most valuable. It has been applied across several industries including manufacturing, mining, and elevators, whereby its longevity can be readily seen in providing speed regulation to electrical motors.

What is Ward Leonard’s Method of Speed Control?

In the 19th century, the Ward Leonard Method of Speed Control was developed to regulate the speed of electric motors by the American electrical controls expert, Mr. Harry Ward Leonard, who designed a control system that provided electric motors with a very high degree of precision in their speed regulation. The system consists of a DC motor, a generator, and a variable resistor, which is most of the time a rheostat. The speed controller of the driving motor controls the motor output speed and therefore the generator generates DC power in the output.

The knob of the manual ensures that the motor runs at a controlled speed through the voltage. By using the strategy you will have not only more precise and stable motor speed control but also more reliable on performing exact operations which for example can be applied to control settings of the manufacturing systems and elevators. The method of Ward Lemma has been tested and verified by the years of the time, however, it became aged and just can be seen in the field of the speed control of electric motors today, and its significance is Important.

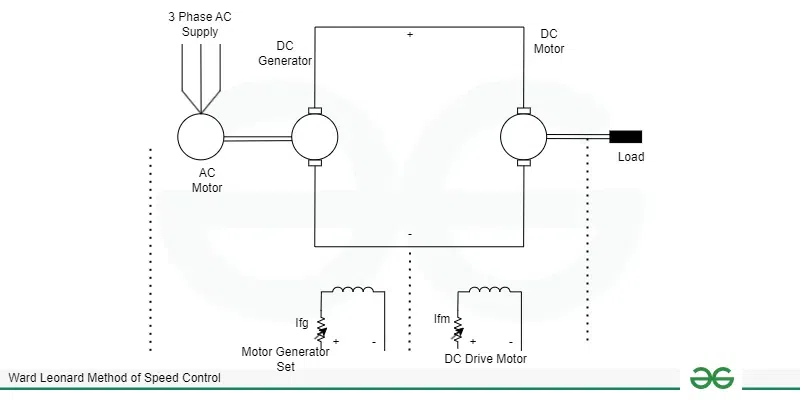

Ward Leonard Method of Speed Control

Principle of Ward Leonard Method of Speed Control

The Ward-Leonard Method of Speed Control, based on the fundamental concept of motor-generator set, enables the regulation of operating speed of an electric motor with high precision. DC motor, which is called as the driving motor, is applied at the base of the system and it is in connection with the load motor which demands speed control. A considerable component of this method includes the use of an inverter, which is well-known for the transformation of the energy output from the driving motor into the direct current (DC) power. The versatile variable resistor, typically a rheostat, is the delicately adjustable control that adjusts the optimized motor voltage supplied to the load motor. Voltage adjustment is achieved by the help of the variable resistor and regulate the “load motor” speed which Ward Leonard system has the capacity to deliver a speed control with high accuracy and stability. In short, it relies on the process of electrical energy transmission though the motor-generator set, which gives a reliable way regulating motor speeds in different industrial uses.

Advantages of Ward Leonard System

The Ward Leonard Method of Speed Control offers several advantages: The Ward Leonard Method of Speed Control offers several advantages:

- Precision Control: In true sense, main advantage is system can vary the speed of an object either faster or slower than the other objects. This is of great relevance in technology sectors such as elevators where the machine has to exercise tasks precisely at controlled speeds.

- Smooth Operation: The technology mentioned is capable to carry out the load lifting and lowering in a timely, enjoyable and effortless manner; thus, the mechanical stress and wear are lowered.

- Regenerative Braking: The system has a designed electric generator that helps improve the energy efficiency level. The energy lost during braking and acceleration is converted to electricity and then fed back to electric system.

- Reliability: The reputation of the Ward Leonard Method is relied upon for the effective operation reliability and durability. The is the reason why it is popular for the applications that require the high degree of reliability.

- Flexibility: The modular configuration of the system makes the covering of electrical motors with various power requirements possible. That has been one of the main successes that has pushed it to use in many industry sectors.

Disadvantages of Ward Leonard System

While the Ward Leonard Method of Speed Control offers several advantages, it also has some disadvantages: While the Ward Leonard Method of Speed Control offers several advantages, it also has some disadvantages:

- Complexity: The system is quite complicated because there are many moving parts involved; motor, generator and variable resistor are few of the components of the system. This will lead to having the higher installation and maintenance costs.

- Energy Losses: Generator is the medium of transformation of electrical energy from the driving motor to the load motor through it. The losses through this process make the system less energy-efficient than the modern controllers.

- Size and Weight: One of the drawbacks of motor-generator device is that it can be cumbersome and bulky, especially for applications requiring more power, which creates a problem for the environment that the space and weight constraints are much more important

- Maintenance Requirements: Such system need more maintenance than some of electronic speed control systems that are based on the solid-state. Components consisting of brushes and commutators, as in the dc motor and generator, usually need periodic care.

- Limited Overload Capacity: Because of its limited overload capacity, it could fail to deal with the increase in the load quickly.

Application of Ward Leonard System

The Ward-Leonard speed control method has shown effectiveness in various sectors where the exact and steady speed of electric motors is the primary focus. Some notable applications include:

- Elevators: The Ward- Leonard system has been traditionally implemented to control the speed and movement of the elevator car. As a precise control is offered by this method it gives you a smooth and accurate transition from floor to floor.

- Steel Rolling Mills: In the steel rolling manufacturing sector mostly, the Ward Leonard Method is applied to regulating motors which supply the driving force for rolling equipment. Hence, it requires reliable speed control to get sheet metal formation and shaping right.

- Mining Equipment: It is utilized in mining activities for instance to regulate the speeds of conveyor belts and other devices to make mining operations run smoothly, safely and efficiently.

- Paper Mills: The Ward Leonard systems have been used in paper mills for controlling the speed of the motors driven to different stages of paper manufacturing thus maintaining uniform quality and efficiency of production.

- Ship Propulsion Systems: In some marine applications, the Ward Leonard Method has been used to control the speed of electric motors driving ship propulsion systems, providing precise control for maneuvering and efficiency

Comparison with Other Method

|

Aspect

|

Ward Leonard Method

|

Field Control Method

|

Armature Voltage Control Method

|

Rheostatic Control Method

|

|

Principle

|

Voltage control

|

Field current control

|

Armature voltage control

|

Armature voltage control

|

|

Speed Control Range

|

Wide

|

Moderate to Wide

|

Limited

|

Limited

|

|

Efficiency

|

Good

|

Good

|

Moderate to Good

|

Poor

|

|

Size and Weight

|

Bulky and Heavy

|

Moderate

|

Compact

|

Compact

|

|

Maintenance

|

Moderate

|

Low

|

Low

|

High

|

|

Cost

|

High

|

Moderate

|

Moderate

|

Low

|

|

Dynamic Response

|

Excellent

|

Good

|

Moderate

|

Poor

|

|

Regenerative Braking

|

Possible

|

Not common

|

Not common

|

Not common

|

|

Applications

|

Heavy-duty applications

|

General-purpose

|

Light-duty applications

|

Light-duty applications

|

Conclusion

The Ward Leonard speed regulation technique, invented by Harry W. Leonard early in 20 century, has been a significant technical input to the electric motors development to possess the exact and stable speed control. Besides, its value in the areas of elevators, steel rolling mills, and mining, where a high degree of accuracy is required is seen in applications where precision mechanical needs.

Yet, it is to be underscored that the emergence of other electronic control methods has led to the emergence of technologies such as VFDs, DTC, and e-drives. More often than not these options are energy more effective, compact and flexible which of course will give them a competitive edge over the traditional Ward Leonard method.

Working out the speed regulation principle, the user should take into account the particularities of the expected application conditions, with efficiency, size, and response speed being the main issues. Although, it may suffer from some shortcomings, Ward-Leonard Method is still used in particular areas, so once again, emphasizes its permanence in the industrial conditions where the speed of precise control is of the special importance. Hence, with the development of control technology, it divides the field of industrial speed control into the categories of selection according to the requirements of different tasks.

FAQs on Ward Leonard Method of Speed Control

Why is it critical to properly control the speed in situations such as elevators?

With proper speed control elevators travel between floors in a smooth manner giving comfort and safety to the ones who are inside.

Is the Ward-Leonard principle suitable for AC motors?

While it was meant for DC motors in the past, the method can be also used with AC motors provided that rectifiers are added.

What can be understood by regenerative braking in the context of the Ward Leonard method?

Regenerative braking is a technology that allows the system to harvest and recycle braking or deceleration energy which is helpful for the energy efficiency objectives.

Share your thoughts in the comments

Please Login to comment...