We have seen how technology has advanced to the point where every resource is being used as a potential that can be used to solve certain purposes. One device is a Steam Boiler which is a device used on a commercial scale for heating water. Its certain qualities make it a perfect heating device.

To utilize the energy of a steam Boiler, we require a proper set up which is done mainly in industries on a large scale. In this article, we will see what a Steam Boiler is, and what are the necessary components of a Steam Boiler. We will also understand the workings of a Steam Boiler through its diagram.

Later, we will try to throw light on some advantages and disadvantages of the Steam Boiler. We will also see some real-life applications of Steam boilers. To understand the characteristics of the Steam Boiler, we will study the characteristics and types of Steam Boiler and all the characteristics that it must satisfy. Later, we will conclude the article with some Frequently asked questions.

What is a Steam Boiler?

A steam boiler is a device or a whole component that is used for heating water. It is important to note that heat doesn’t necessarily boil water, it just heats it up enough. The whole heating process is done in a closed vessel-like structure. It uses some kind of fuel to generate heat which is then given to water. The combination of heat and water generates steam. This steam can later be used for various commercial purposes like industrial heating, cleaning, and cooking. A steam boiler is mainly defined by its structure, components, and working. Let us now see these.

Key terminologies used in Steam Boiler

Here is a list of terms that you need to know before working with steam boiler.

- Efficiency: Steam boiler efficiency can be defined as the ratio of outlet steam in the total heat supplied by the total fuel supplied. Higher the efficiency better the boiler.

- Burner: As the name suggests ,it is that component of steam boiler which is responsible for generating heat mainly by the combustion of fuel and is therefore called burner.

- Boiler: Boiler is the high -pressure component of steam boiler which performs the task of converting all the water to steam.

- Combustion: The combustion chamber has tubes containing water and steam that pass through the a box with the burner and controls. This process is used to generate a lot of heat.

- Furnace: Furnace can be describes an essential unit that plays a large role in heating part of boiler. It is almost mostly self-equipped with a lot of closely set water-tubes that help in heat generation.

Construction and Components of Steam Boiler

Let us now see the construction of steam boiler

Steam Boiler

The steam boiler consist of a major components known as the steam drum. The drum is usually pivoted at the end and is fabricated from steel to create a thick covering around the boiler. The main purpose of this steam drum is to ensure the separation of water from the steam before letting it go to the other outlet. This is why the size of drum should be sufficiently large to allow the separation.

Another important components of steam boiler is water drum. It performs the task of feeding water to different components like generating tubes. It also performs the task of collecting the precipitate of various processes. Some manufacturers might replace the water drum with header and the downcomers.

Generating tubes are large number of tubes with large diameter that ensure proper flow of gases to different components of boiler .They can mainly be used for passing steam and water from one part of chamber to another. Depending on the requirements, we can decide the number of Generating tubes.

Superheater Tubes are large diameter tubes to control the gas flow in the boiler. Since the steam has low heat capacity these tubes require protection from over-heating mainly in the low steam flow conditions. The liquid( mainly water) also performs the cooling task ensuring that no product gets heated to such an extent that it begins self-heating. Almost all tubes are covered around by water for protection.

After all the heating has been performed ,there is some extra heat as the residue .This is like a waste product after the whole process and needs some outlet to escape from the system. Vapor Outlet is responsible for letting out all the waste vapours out from the system. Some of the heavy residue like contaminants in water settle down instead of vaporizing up and are let out throw a bottom product present at the end and bottom of the system.

Working of Steam Boiler

To understand the working of a steam boiler we need to understand that a steam boiler consist of a close cylindrical shape. This whole device consist of the operating system of steam boiler. Generally a liquid is stored in the boiler in most of the cases this liquid is water because of its favorable characteristics. This liquid is further used for generating steam that will operate the boiler. The water is then sent to the heating chamber called furnace . The furnace is a crucial component of the whole boiler since it performs the task of heating up the fluids. The whole furnace is heated up by the combustion of fuels such as coal. This heat then converts the water which reaches it through various tubes into steam.

Now ,we have steam which is processed through water . Note that this steam is under high pressure which is a necessary requirement. This steam is pure and can be used for various commercial purposes . In order to make this steam available for commercial use, the steam is transported to outlet through various pipes that are spread in the entire steam boiler. While the unsaturated steam is used for commercial purposes, the saturated steam settles at the bottom and is taken out of the system. Pure steam is mainly used fir generating power in power plants.

Types of Steam Boiler

Types of Steam Boilers are given below

- Hot Water Boilers

- Electric Boilers

- Gas Boilers

- Low Pressure Boilers

- High Pressure Boilers

- Water Tube Boiler

- Fire Tube Boiler

- Package Boiler

- Stoker Fired Boiler

Hot Water Boilers

Hot water boilers are a type of boilers in which heat is transferred throughout the system to water in order to heat up the water. Since these boilers operate at a high range of temperature, it is necessary to design them using a material that can withstand high temperature and is durable .Therefore these boilers are made using materials like stainless steel, cast iron, aluminium and iron that can withstand high pressure and temperature.

Hot Water Boiler

Electric Boilers

Electric boiler performs the same function as any boiler but it has a different construction and design. It doesn’t use the conventionally steam method to generate heat in the system rather it uses electric means to generate heat in the system. Electric elements that heat up when provided with electricity are used. This makes electric boilers more energy efficient and eco-friendly since no fuel is consumed up. Due to no fuel requirement ,it doesn’t leave any residue. They are generally categorized to be long lasting maintenance free because they require minimal cleaning.

Electric Boiler

Gas Boilers

Gas boiler performs the same function as any boiler but it has a different construction and design. A gas boiler uses natural gas or methane as a replacement of steam which is used in standard boilers. The use of natural gas makes gas boilers more efficient . The fuel of gas boiler i.e. methane is led into the gas boiler through a pipe which brings it from some outlet into the boiler. The configurations of gas boilers can vary and ultimately affect the way in which fuel is getting distributed. Usually gas boilers are used for industrial and commercial purposes.

Gas Boiler

Low Pressure Boilers

Low pressure boilers performs the same function as any boiler but it has a different construction and design. As the name suggests, these boilers within a pressure range of around 10 and 15 psi with a temperature constraint of 300° F (149° C). These boilers come into use when a consistent temperature range is required rather than the one where temperature changes quickly. These boilers are popular mainly because they can deliver steam at a much faster rate than any other boiler.

Low Pressure Boiler

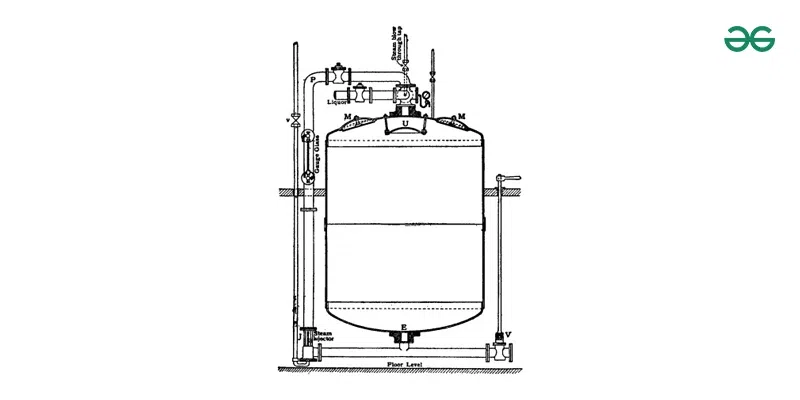

High Pressure Boilers

High Pressure Boilers performs the same function as any boiler but it has a different construction and design. These boilers require to create excessive pressure to power equipment and machinery. Usually a pump is used to generate so much force and pressure required to create the steam at high pressure into the circulation system. The typical range where a high boiler operates is around 5 psi and 800 psi at temperatures which should be greater than 250° F (121° C). These devices need to be monitored regularly because of high pressure in the system. They can be categorized into two types namely batch or continuous.

High pressure boiler

Water Tube Boiler

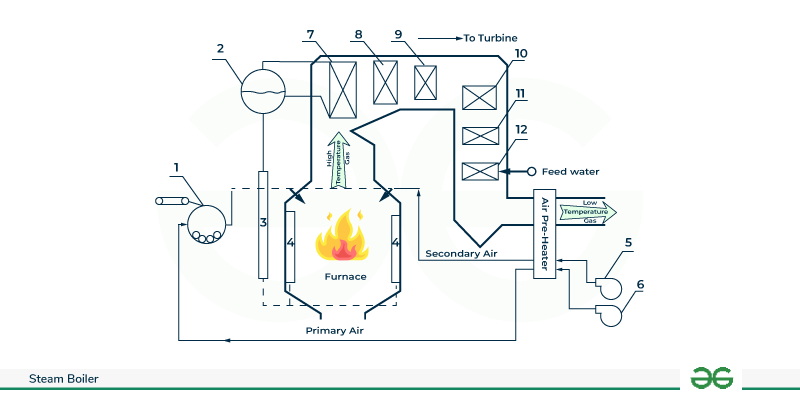

Water tube boilers are a type of boilers in which water is carried throughout the system using tubes in order to generate heat . Since these boilers operate at a high range of temperature, it is necessary to design them using a material that can withstand high temperature and is durable .The tubes that carry the water are then heated to generate steam. Here is a diagram representing how does a water tube boiler works. Note how the water is stored in tubes.

Water Tube Boiler

Let us see the principle that dictates how the water boiler works. here is the principle

The water boiler works on the principle that combustion of fuels can generate heat which can be used to boil the water and generate steam at high pressure. This high pressure steam can then be used for generating power for commercial purpose.

Water boilers are quite useful devices and are mainly popular because:

- They have enhanced efficiency because they convert the fuel into a usable energy and they minimize the heat loss.

- They are quite versatile and adaptable. The steam generated from steam boiler can be used for various versatile purposes like power generation, cooking and even heating.

- Water boilers are reliable in the long -term. They require minimal maintenance meaning that they don’t require much update in the long-run.

- These boilers are quite safe and can be operated without any fear.

- These devices are fast operating and generate steam very rapidly.

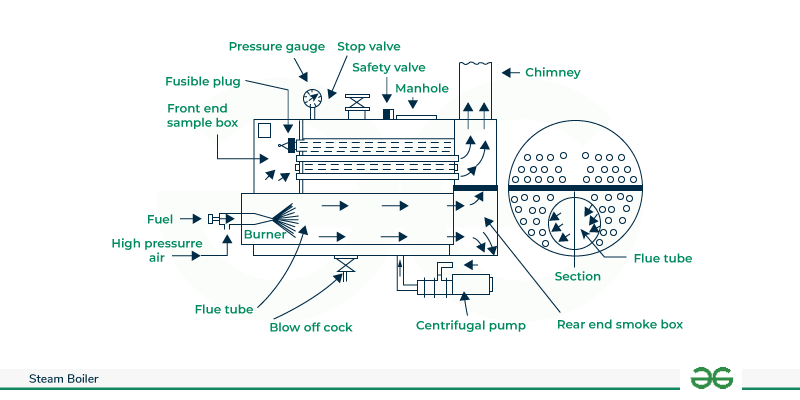

Fire Tube Boiler

Fire tube boilers are a type of boilers in which water or the fluid that is meant to be heated flows through tubes that are constantly surrounded by fire. This is in contrary to a watertube boiler, in which the fire flows through tubes which is surrounded by water. Note that the way it operates, it can be difficult to use fire tube boilers are large scale therefore they are used on small scale to perform small operations like heating and cooking. Here is a diagram representing how does a fire tube boiler works. Note how the fire is stored in tubes.

Fire Tube Boiler

Package Boiler

As the name suggests, a package boiler is a types of boiler that has been packed completely meaning that entire boiler and its components have been assembled and the boiler is ready to use once it’s deployed on the site. Once it reaches the destination only some connection of Essential parts is required because all other pressure components have been stuck together. This type of boiler generates high heat using methods like radiation and convection which gives this boiler High thermal efficiency and better heat transfer. Here is a diagram representing how does a package boiler works. Note how all connections are made.

Package Boiler

Stoker Fired Boiler

Stoker-fired boilers are used in many programs that have a requirement of thermal capacities under 50 MW. In those boilers, the gas is fed by a stoker onto the furnace, in which it is ignited by way of warmth from the refractory above. because the gasoline travels down the grate, it maintains to burn, with number one air coming from below. once it reaches the stop of the grate, the non-combustible residues fall into the ash pit. meanwhile, the flue gases tour into a blending chamber in which the combustion procedure is finished, subsequently passing through the warmth exchanger in which they surrender their warmth to generate steam.

Stoker Fire Boiler

Characteristics of Steam Boiler

Here are some characteristics of a good steam tube boilers:

- A good steam boiler must have high efficiency . This means that it should generate maximum amount of steam and use minimum fuel at the same time. Commercial steam engines require an efficiency of around 80%.

- A good steam boiler must be light weight and compact ensuring that it requires minimal space in any unit. Low weight makes it easier to carry around.

- The time required for getting a steam boiler required must be low. This means that the steam boiler must show immediate starting and start operating as soon as it is turned on.

- A good steam boiler must be economical ensuring that it comes within the budget range. Due to low cost of installing these devices ,they become a first choice for commercial units.

- A good steam boiler must require minimal maintenance . This means that after the boiler has been installed ,it requires almost zero concentration and can operate optimally without much maintenance.

Advantages of Steam Boiler

Some advantages of steam tube boilers are given below

- The whole construction of whole boiler is quite compact. Almost everything is included in one singles chamber which encloses all the tubes and compartments.

- Depending on the requirement of steam, we can control the amount of steam generated by indirectly increasing or decreasing the water supply. In short we can meet any fluctuation in steam requirement.

- The maintenance cost of the system is quite low. You only need to invest initially and after that the system requires minimal maintenance and easy to use.

- Steam boilers have high efficiency which ensure great output returns for every input. This is important in industrial industry since it guarantees greater returns and better profits.

- The whole process almost releases zero emissions i.e. minimal residue after the whole pocess. This is because it uses water as the main components which releases no residual waste that needs to be disposed. There is only some extra steam which can be let out easily.

Disadvantages of Steam Boiler

Some disadvantages of steam tube boilers are given below

- The whole process takes a lot of time mainly because the whole process begins only after all the water has been converted to steam making the process time longer .

- The quantity of water required for such processes is very large. Since steam boilers generate steam on a very large scale, the requirement o water is very high which means that every time you want to use steam boiler, you need to arrange large amounts of water.

- The whole process has a high setup cost because of the equipment’s involved. Arranging these components require a lot of money and therefore make the initial cost of setup high.

- The vessels that are used for steam and water are not different therefore it is not possible to achieve very high pressure steam which is a necessary requirement for heat generation.

- The moisture content of steam is quite high even after the process. This is not a viable property of steam boiler as we require steam with minimal water content.

Applications of Steam Boiler

Some applications of steam tube boilers are given below

- A steam boiler can be used for generating heat and steam which can be then used in different applications . The hot water can be used to heat water for domestic or commercial use depending on the size of production unit.

- The steam generated from steam boiler can be used for generating power for industrial purposes. In various industries, this steam is processed and converted in a form to generate power which then operates devices.

- The steam generated from steam boiler can be used for medical purposes as well. The steam generated from such processes is pure without any contaminants hence can be used for Sterilizing medical equipment.

- The heat generated from steam boiler can be used for various different domestic processes . For examples it can be used for cooking and drying purposes in houses.

- The steam generated from steam boiler can be used potentially used to drive turbines due to the pressure of steam .These turbine rotations can then convert the mechanical energy in any other form of energy which is required.

Conclusion

We have seen how Steam Boiler makes an integral part of modern industries. The need of hot water is felt almost everywhere including some power plants therefore it was necessary to introduce some device that efficiently converts water to steam for commercial purposes. This article has provided us a deep insight as to what a Steam Boiler is and what are its characteristics that distinguishes it from other major devices in market. Steam Boiler although has multiple benefits yet it has some of its own limitations which are stated above .Advancements are being made in this field and expected that readers develop some questions in regard to the topics they studied .Therefore, they are advised to refer to the Frequently Asked questions to clear all doubts.

FAQs on Steam Boiler

Is it necessary to use fuel to heat up water in a boiler?

No we can heat up the water in a boiler using other means like electric furnace or gases like methane and propane.

Which process is used for generating heat in a steam boiler?

Combustion is the process which generates heat required for heating up water in a boiler. Combustion is the process by which fuel is heated up in furnace.

How much power can a steam boiler generate?

Generally speaking, most turbines are capable of producing up to 50 kilowatts (kW) if they are the right size and powered by an efficient steam boilers.

Share your thoughts in the comments

Please Login to comment...