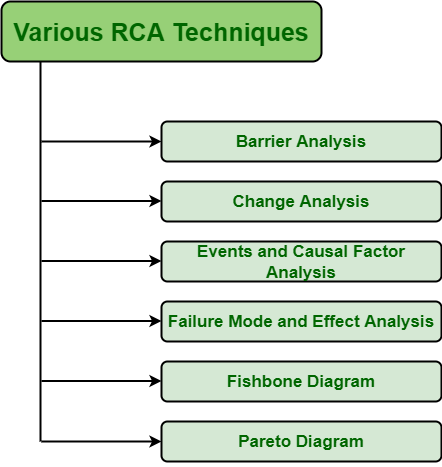

Various RCA Techniques

Last Updated :

30 Sep, 2020

Root Cause Analysis (RCA) is a reactive method that is used to detect problems and then solve them. One needs to understand that problems are best solved by resolving or eliminate their root causes rather than solving symptoms of problems or defects. Eliminating root causes will only lead to minimization in the reoccurrence of a particular problem. There are various RCA techniques available nowadays that are beneficial for various organizations. Some of the techniques are given below –

- Barrier Analysis :

Barrier Analysis, as the name suggests, is a technique that is used to investigate pathways that have a negative impact on the target product. It simply analyzes why and how barriers did not prevent energy flows from causing a negative impact. It is simply a model or technique that is used by several organizations to know that why a defect occurred and how it can prevent reoccurrence. It is applied to safety-based RCA but can be used for other different problems also. It is particularly used in process industries.

- Change Analysis :

Change Analysis, as the name suggests, is a type of analysis that is used to compare change that is occurred to situations where change doesn’t exist or occurred. Here, change is considered a problem or defect. Changes are simply caused due to problems or defects. So, change analysis simply determine what, where, how, and extent of the problem, and then compare it with conditions or situations where a particular defect is not present.

- Events and Causal Factor Analysis :

Events and Causal Factor Analysis, as the name suggests, is a technique that is used commonly for both accidents as well as other major incidents. In simple words, this analysis technique simply analyzes events that lead to incidents and identify causal and contributing factors that are possible for each event.

- Failure Mode and Effects Analysis (FMEA) :

FMEA is basically a system engineering process to analyze failure in system processes or products. It is simply done to identify failures that might exist within the process of the system or design of the product. In this, defects or problems are prioritized on basis of their severity.

- Fishbone Diagram :

The Fishbone diagram, also known as the Ishikawa Diagram, is a technique basically used during brainstorming. It is one of the best methods due to its simplicity and less complexity as compared to other methods that are highly complex and difficult. In this technique, possible effects or causes of problems or defects are analyzed.

- Pareto Diagram :

Pareto Diagram is a technique that is used to analyze only a limited number of defects or problems and their causes. It simply states that 80% of problems or defects are caused only due to 20 % of the problem. Therefore, it only focuses on top causes that are needed to resolve or eliminated simply to solve more defects or problems.

Like Article

Suggest improvement

Share your thoughts in the comments

Please Login to comment...