Run-to-Failure (RTF) Maintenance

Last Updated :

09 May, 2023

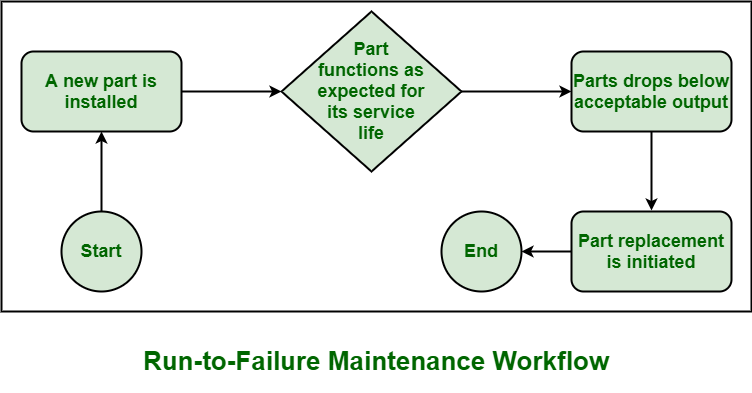

Run-to-Failure (RTF) maintenance, also referred to as fit and forget maintenance, is a type of maintenance strategy that follows simple rule i.e. wait until fail. One has to wait till equipment runs to failure i.e. wait until equipment gets failed or gets broken down. After failure, one can fix it or replace it. This is one of cost-effective strategy and is only applicable if effects and consequences of failure are tolerable and cost associated with equipment failure and its repairment is less or negligible. This strategy is widely used nowadays by several companies and organizations that have various types of equipment. This maintenance strategy is unplanned but in actual, it is a planned strategy that is being designed to reduce maintenance cost of equipment. Team members are also prepared to take measures and perform actions as soon as failure occurs.

Features of RTF Maintenance :

- Real-time monitoring: RTF maintenance relies on continuous real-time monitoring of equipment using sensors and other data collection tools. This allows for immediate detection of potential faults and abnormalities.

- Predictive analytics: RTF maintenance uses predictive analytics to identify patterns in equipment data that may indicate potential faults or failures. By analyzing data trends, RTF maintenance can detect problems before they occur.

- Condition-based maintenance: RTF maintenance is a condition-based maintenance strategy that focuses on the actual condition of equipment, rather than just its age or usage. By monitoring the condition of equipment in real-time, RTF maintenance can make more accurate maintenance decisions and reduce downtime.

- Automated alerts: RTF maintenance systems are designed to automatically alert maintenance personnel when potential faults are detected.

- Remote monitoring: RTF maintenance systems can be monitored remotely, allowing maintenance personnel to access real-time data and alerts from anywhere. This can help reduce response times and improve overall maintenance efficiency.

- Integration with other systems: RTF maintenance systems can be integrated with other systems, such as enterprise asset management (EAM) systems or computerized maintenance management systems (CMMS).

Applications of RTF Maintenance :

- Manufacturing: In manufacturing plants, RTF maintenance can be used to monitor critical equipment such as conveyors, motors, and bearings. By using sensors and data analytics, potential faults can be detected and addressed before they lead to a breakdown, reducing downtime and increasing efficiency.

- Aviation: In the aviation industry, RTF maintenance is crucial for ensuring the safety and reliability of aircraft. By monitoring various systems, such as engines, avionics, and hydraulics, potential faults can be detected and addressed in real-time.

- Transportation: In the transportation industry, RTF maintenance can be used to monitor vehicles such as trains, buses, and trucks. By using sensors and data analytics, potential faults can be detected and addressed before they lead to a breakdown, reducing downtime and improving safety.

- Energy production: In the energy production industry, RTF maintenance can be used to monitor critical equipment such as turbines, generators, and transformers. By using sensors and data analytics, potential faults can be detected and addressed before they lead to a breakdown, reducing downtime and increasing efficiency.

Advantages : There are several advantages of RTF as given below :

- Minimal planning : As there is no maintenance required before failure so planning is not so essential in such type of maintenance strategy. Maintenance is only required and performed after failure has occurred but not before failure has occurred.

- Cost-effective :

RTF is a cost-effective strategy it saves money by simply eliminating maintenance cost of equipment. This strategy does not involve maintenance of equipment before its failure therefore maintenance cost is safe.

- Easy to understand : As maintenance strategy requires very less or minimal planning, one can easily understand working of this maintenance strategy. Because of its simplicity, one can easily implement it without any problem.

Disadvantages : Besides advantages, there are several disadvantages of RTF as given below :

- Unpredictable : There are several failures that are unforeseeable i.e. not able to be predicted. Due to this, one cannot determine when particular assets are needed to be repaired or replaced. So, sometimes it becomes very difficult to resolve issues or problems and it can cause greater damage in future.

- Inconsistent : In such maintenance strategy, failures are usually occurred or reported to occur during use of particular equipment or asset. During analysis, failure was not found, but it occurred during usage of assets. Such failures are considered as intermittent failures that can be caused due to NFF (No-fault-found) occurrences. So, it becomes difficult to plan efficiently regarding fixing it and resources required to fix it.

- Costly : Such maintenance strategy can also be very costly. Sometimes failures can lead to greater damage and require more resources to repair it. This will lead increase in repair cost. This in turn increases production cost, labor costs associated with performing maintenance.

Like Article

Suggest improvement

Share your thoughts in the comments

Please Login to comment...