Difference between MRP and DRP

Last Updated :

29 Mar, 2022

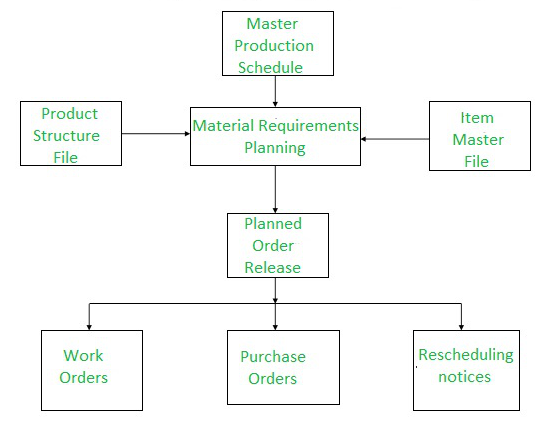

1. Material Requirement Planning (MRP) : Developed in 1970s, raw material whenever required by any organization is managed i.e, which materials are required by company gets stored in a database. Also, it tells about shortage of any material. Material Requirement Planning is widely used approach for production planning and scheduling in industry. It is the approach embedded in many commercially available software applications. Function of MRP is to provide material availability i.e, it is used to produce requirement quantities on time. This process involves monitoring of stocks and demand, leading to automatic creation of procurement proposals for purchasing or production. Main objective of MRP is to determine which material is required, quantity required and by when it is required. It is Factor material inventory and emphasis on physical assets.

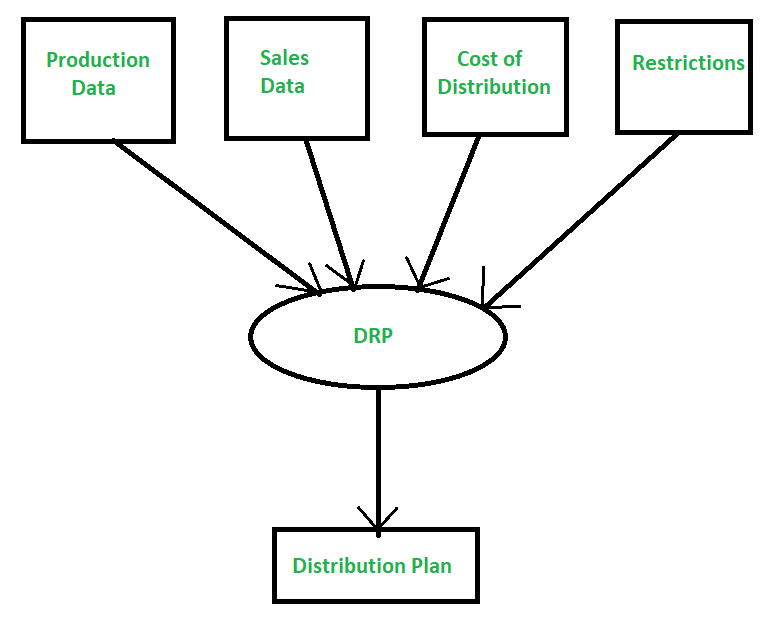

2. Distribution Requirement Planning (DRP) : It is extension of Material Requirement Planning (MRP). It is a process to make delivery of goods efficient by determining its quantity and location where it is more required. It is utilized by firms to ensure availability of right amount of materials at right time and right place. It uses time phased schedule so that it can ensure timely production of end product. The key elements in DRP is: Demands, current Inventory levels, target safety stock, quantities, and replenishment lead times.

Difference between MRP and DRP :

| MRP |

DRP |

| Stands for Material Requirement Planning. |

Stands for Distribution Requirement Planning. |

| It is under the control of the firms. |

It is not under the control of the firms. |

| It controls inventory until manufacturing is complete. |

It controls manufacturing after the manufacturing is complete. |

| It is guided by production schedules. |

It is guided by customer demands. |

| It operates in dependent demand situation. |

It operates in independent demand situation. |

| It coordinates the scheduling and integration of the materials. |

It coordinates the demands between outlets and supply sources. |

Like Article

Suggest improvement

Share your thoughts in the comments

Please Login to comment...