The cotton industry in India has been considered to be the second most developed in the textile industry of India following the man-made textile. India is the largest producer of cotton and the cotton industry of India is one of the fastest-growing sectors. About 25 percent of the world’s area under cultivation is under India and includes states like Gujarat, Maharashtra, Andhra Pradesh, Haryana, Madhya Pradesh, Rajasthan, Punjab and Tamil Nadu. About 4.5 crore people in India have been employed in cotton textile industry of India.

Cotton Textile Industry in India Map

Let us discover the rich tapestry of the Cotton Textile Industry of India through our detailed map, highlighting major production hubs and weaving traditions across the nation.

Textile Industries in India

Cotton Textile Industry in India

Cotton is one of the most highly sought commodities which has been traded since ancient times. The presence of cotton textile industries can be seen since 1818 AD. The areas of the most important cotton textile include 4 regions:

- Western region.

- Southern region.

- Northern region.

- Eastern region.

Growth and Development of the Cotton Industry in India

In the initial time frame, the cotton industry in India was concentrated in Rajasthan, Maharashtra, and Gujarat, where cotton is grown extensively. The availability of raw materials, market, transportation, labor, and humid climate, among other important factors have aided tremendously.

The partition in 1947, has led to the loss of many long-staple cotton-growing regions to Pakistan and India faced a severe shortage of raw cotton. As of 2011, there are 1,946 cotton textile mills present in India and many thousand small factories are there as well.

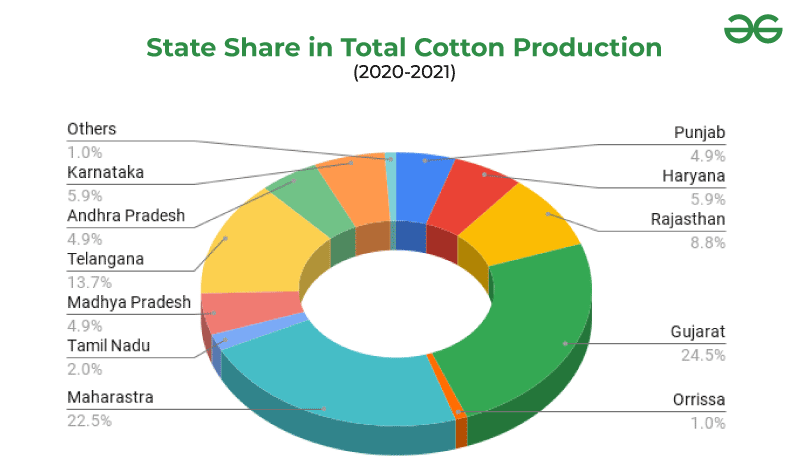

State Share in Total Cotton Production

Background to Cotton Textile Industry

The real advancement of the modem cotton material industry began in the eighteenth century with the modern transformation in Great Britain. It got energy after the innovations of the Flying Shuttle (1733) by Kay, the Spinning Jenny (1764) by Hargreaves, the Spinning Mule (1776) by Crompton, the Power loom (1787) via Cartwright, and Steam Engine and Cotton Gin (1793) in Extraordinary Britain, From Great Britain, present-day innovation of turning and winding of cotton fabric reached to numerous nations of Europe and to the U.S.A., Japan, and India in the nineteenth country.

In the 20th century, this innovation was created in the previous USSR, China, Egypt, Turkey, Mexico, Brazil, etc. The cotton material industry is very broad on the planet and upwards of 90 nations are creating cotton yarn as well as material in fluctuating amounts. Be that as it may, the primary grouping of the material industry is restricted to not many nations. There are two kinds of creation related to cotton material, one is the development of cotton yarn and one more is the creation of cotton fabric. Albeit numerous nations produce both things.

Current Position of Cotton Textile Industry in India

India’s largest organized sector in modern times is cotton textile and employs about 16 percent of the country’s capital and over 20 percent of industrial labor. At present, there are 1,719 textile mills in India and tens of thousands of small factories.

Locational Factors for Cotton Textile Industry in India

Like different enterprises, the cotton material industry additionally expects to amplify benefits by limiting the creation cost. To decrease the absolute use or cost of creation and supply to business sectors, the business needs to figure out the smallest expense ‘area. In the determination of a reasonable size for a cotton material industry, the accessibility of talented work, market, and method for transport assumes a vital part.

- Raw materials: Cotton is an unadulterated natural substance as the proportion of crude cotton and wrapped-up item. Cotton string and material are almost something very similar. It is tracked down that the weight reduction of crude cotton (without cotton seeds) is immaterial to produce.

- Market: The interest in apparel is constantly directed by design. Generally speaking, made material products are noteworthy in nature. Through time, the flavor of shoppers and the style of the general public will more often than not change especially.

- Climate: Moist mild environment is viewed as an ideal condition for the improvement of the cotton material industry. The greater part of the material enterprises was set up in gentle and muggy climatic areas in the nineteenth and twentieth hundreds of years.

- Labor: The cotton material industry is essentially a work-escalated industry. Gifted and modest work is expected by the material business. Many works including the treatment of current machines rely generally upon the work prepared for the business.

- Power Resources: The stock of shows of dominance a significant job in the limitation of the cotton material industry. In the beginning stage of improvement, material ventures were situated close to the water source: waterways, lakes, oceans, and so forth.

- Transport: Suitable method for transportation is expected for the assortment of unrefined components, what’s more, dissemination of completed products: cotton yarn, and cotton fabric to the market. These things might be shipped by trucks (street transport), rail line carts, and ocean vessels.

- Capital: A lot of capital is fundamental for the foundation of any cotton factory. A cotton material industry running on a limited scale or family premise requires little capital however an enormous scope plant needs a colossal measure of fixed and portable.

Distribution of Cotton Textile Industry in India

The highest concentration of cotton textiles is included in Maharashtra, Gujarat, West Bengal, and Uttar Pradesh. They are some of the leading cotton textile producers.

| States |

Characteristics |

| Maharashtra |

- Maharashtra is the leading producer of cotton textile industries.

- Manufactures about 39.38 percent of mill cloth.

- Employment of about three lahks of the population.

|

| Gujarat |

- Gujarat is the second-largest cotton producer in the world.

- Produces about 33% of the mill cloth

|

| Madhya Pradesh |

- There is an abundance of cheap labor due to the backward economy.

- Important centers include Gwalior, Ujjain, Indore, etc.

|

| Tamil Nadu |

- It is a major cotton producer in the southern states.

- Coimbatore is the most important center, with 200 mills.

|

| West Bengal |

- Kolkata is the most important center.

- Other important sites are Haora, Murshidabad, Hugli, Sirampur, etc.

|

| Uttar Pradesh |

- The western part of the state grows most of the textiles.

- The important centers include Moradabad, Varanasi, Agra, etc.

|

| Punjab |

- New cotton varieties like BT cotton has been introduced.

- Important centers of Punjab cotton textiles include Amritsar and Ludhiana.

|

Types of Cotton Textiles

There are various types of cotton textiles that are produced in India. These include:

.webp)

Types of Cotton

- Khadi: Khadi is a hand-woven fabric made from cotton that is typically used for clothing. It is also sometimes referred to as “homespun cloth”.

- Calico: Calico is a plain-weave cotton fabric that is often printed with patterns. It is commonly used for making garments, bedding, and other household items.

- Muslin: Muslin is a finely-woven cotton fabric that can be either plain or patterned. It is often used for making dresses, shirts, and other garments.

- Denim: Denim is a sturdy cotton twill fabric that is typically blue in color. It is most commonly used for making jeans, but can also be used for other garments such as shirts and jackets.

- Chambray: Chambray is a lightweight cotton fabric with a plain weave that can be either solid-colored or patterned. It is often used for making shirts, dresses, and other garments.

Government Initiatives

The government of India has come to enact certain policies for the promotion of cotton textiles. In October 2021, there has been an announcement for the establishment of 100 textile machinery in the country for the promotion of world trade and the growth of cotton textile industries. MUDRA Scheme has been established for the assistance of handloom weavers.

Challenges of Cotton Textile Industry in India

The following are the important challenges of the cotton textile industry in India :

- Scarcity of Raw Cotton: Since the partition, the Indian cotton textile industry has suffered as cotton growing areas went to Pakistan.

- Outdated Machinery: Around 60-70% of the machinery in India is 2 to 3 decades old.

- Erratic Power Supply: Power supply to cotton mills is erratic and insufficient.

- Low Labour Productivity: A worker in India has two looms on average as compared to 30 looms in Japan and 60 looms in USA.

- Strikes: Frequent strikes can be seen in the cotton textile industry.

- Tough competition: Stiff competition can be felt in the Indian cotton mill industry in terms of handloom and power loom.

Significance of Cotton Textile Industry in India

India is ranked as the second-largest cotton producer with the largest cotton-growing area in the world. It has the advantage of low-cost cotton sourcing and the average wage rate in India is about 50-60% lower than in developed countries, which benefits India in case of global outsourcing trends.

The industry has been investing in technology and is also trying to expand its capacity for the strengthening of relationships with other sectors. Design and capabilities also have come to help Indian companies for strengthening their relationship with global players.

Exports from Cotton Textile Industry in India

Cotton is one of the major exports from India and cotton yarns, clothes, etc are among the most important exports. Garments from India are well known around the world and so readymade garments export increased drastically from 1960. Exports from India cover USA, Russia, United Kingdoms, Sri Lanka, and so forth countries.

Recent Schemes Related to Textile Sector in India

| Scheme |

Features |

| Amended Technology Upgradation Funds Scheme (ATUFS) |

It refers to Credit Linked Capital Investment Subsidy (CIS) for exports with “Make in India” with “Zero Effect and Zero Defect” in their manufacturing. |

| North-EastNorth-East Region Textile Promotion Scheme (NERTPS) |

The aim is for providing infrastructural, capacity- building and also marketing support for North- East India. |

| Scheme for Integrated Textile Parks (SITP) |

It was first launched in 2005 to encourage private investments and employment generations in the textile industry for a good infrastructure for important facilities. |

Conclusion

The Indian cotton textile industry is one of the largest in the world, with a production capacity of over 5 million tonnes. In recent years, the industry has been facing challenges due to increased competition from cheaper imports, particularly from China. The Indian government has been providing support to the industry through various measures such as subsidies and duty-free imports of raw cotton. In spite of these measures, the industry is struggling to compete with Chinese manufacturers who have scale advantages and lower costs.

Looking ahead, the future of the Indian cotton textile industry depends on its ability to increase productivity and efficiency, while reducing costs. The industry will also need to focus on developing new products and applications for cotton that can compete with other synthetic fibers.

Related Links

- Protest against import of India Textile in England

- Important Inventions of the World

- Important Industries In The World

- Indian Textiles and the World Market

- Industrial Revolution in Britain: Causes and Effects

- List of Towns Associated with Important Industries

- Types of Synthetic Fibers

FAQs on Cotton Textile Industry in India

Q 1. What type of industry is cotton textile?

Answer-

The cotton textile industry is an agro-based industry, as these industries depend on agricultural produce Few other examples are jute, silk, etc.

Q 2. Which is the largest cotton textile industry in India?

Answer-

The largest cotton textile industry in India is Maharashtra as there is availability of raw materials and traditionally skilled labour.

Q 3. Where is the cotton textile industry in India?

Answer-

The states in which the cotton textile industry is concentrated include Gujarat, Maharashtra, Andhra Pradesh, Punjab, and Tamil Nadu.

Q 4. Which city is famous for the cotton industry in India?

Answer-

Ahmedabad is famous for its cotton industry and is often known as the “Manchester of India”.

Like Article

Suggest improvement

Share your thoughts in the comments

Please Login to comment...